Specializing in low-voltage three-phase squirrel-cage induction motors

Predictive maintenance service

For companies in various industries

We are taking advantage of it!

food

beverage

Pharmaceuticals and cosmetics

Papermaking/printing

Semiconductors/Electronics

plant equipment

Nissei Co., Ltd.

At the Biwako Plant

sudden downtime,

Aren't you giving up because you can't help it?

Is there such a thing?

Sudden motor failure!

no spare

Downtime occurs...

due to motor failure

valuable material

To discard...

I want to expand my production facilities

but lack of staff

Worried about maintenance...

From data collection to abnormality diagnosis, this one unit!

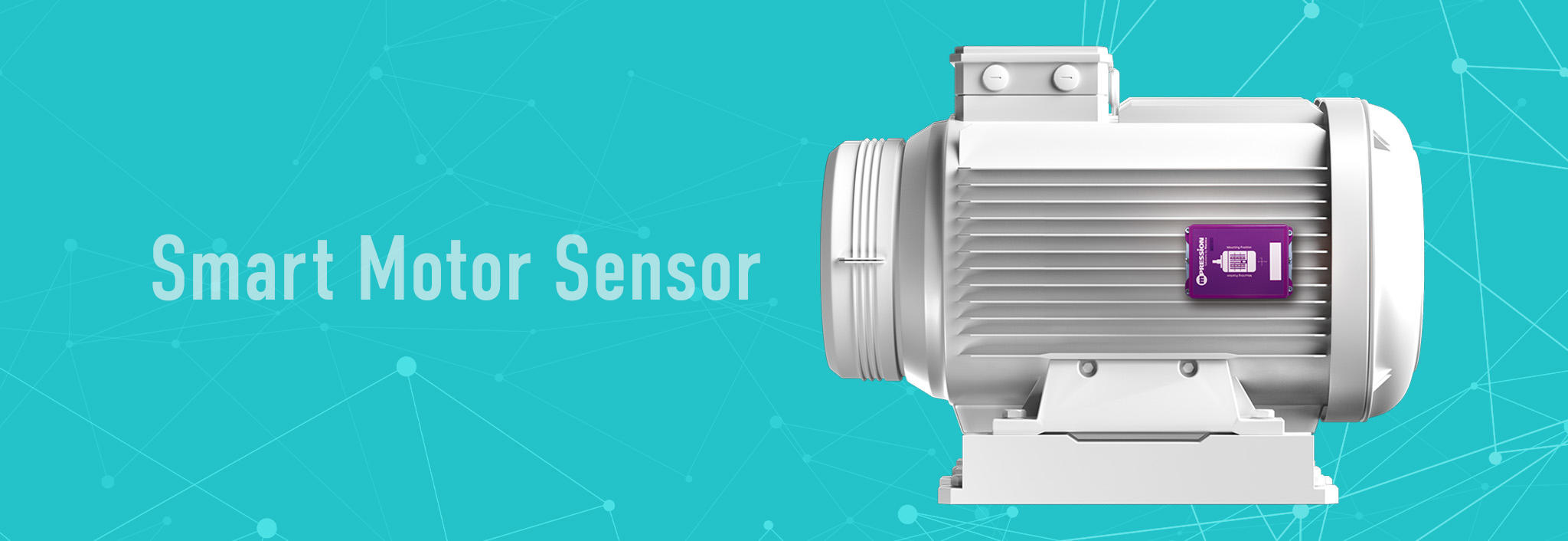

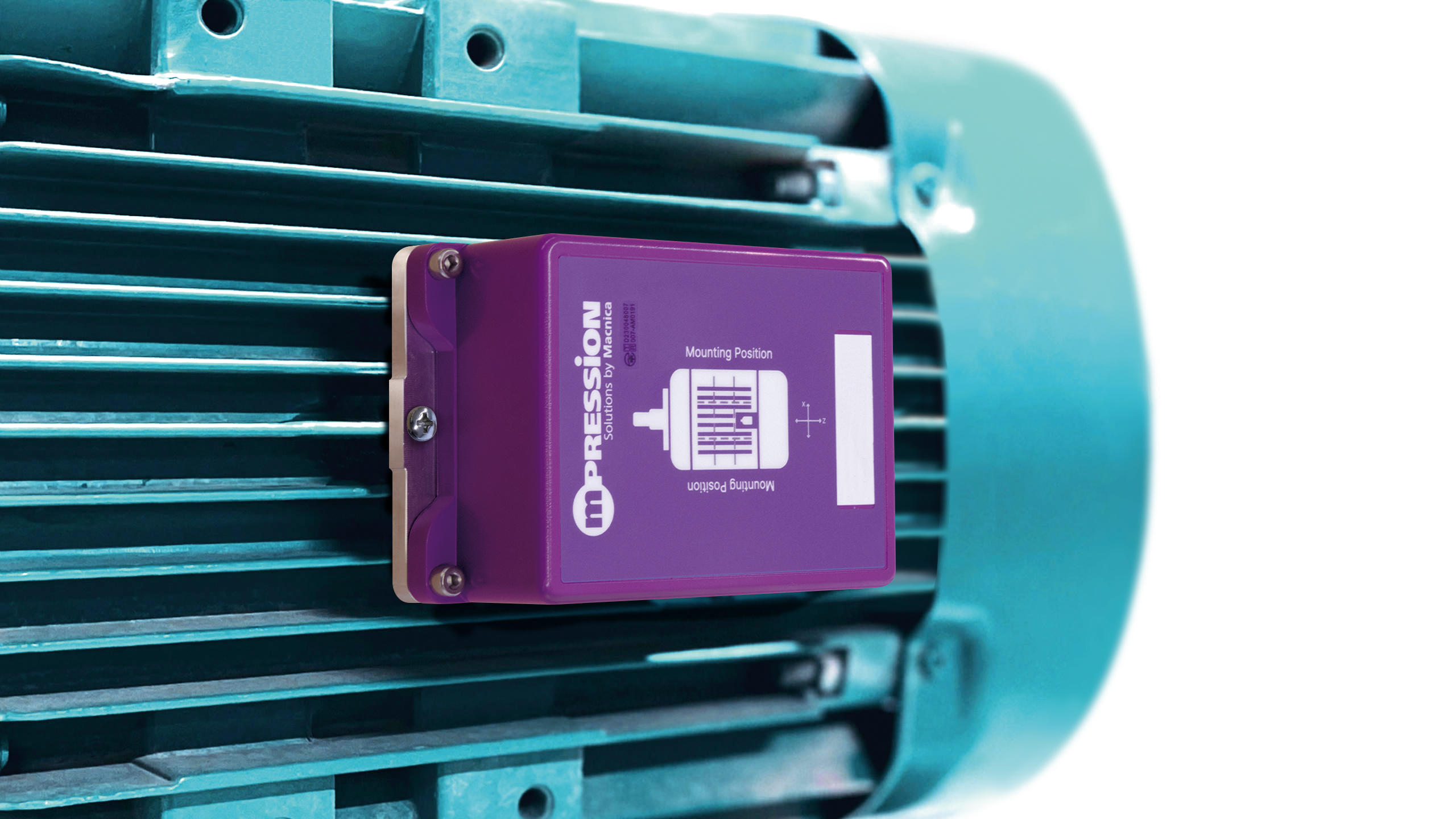

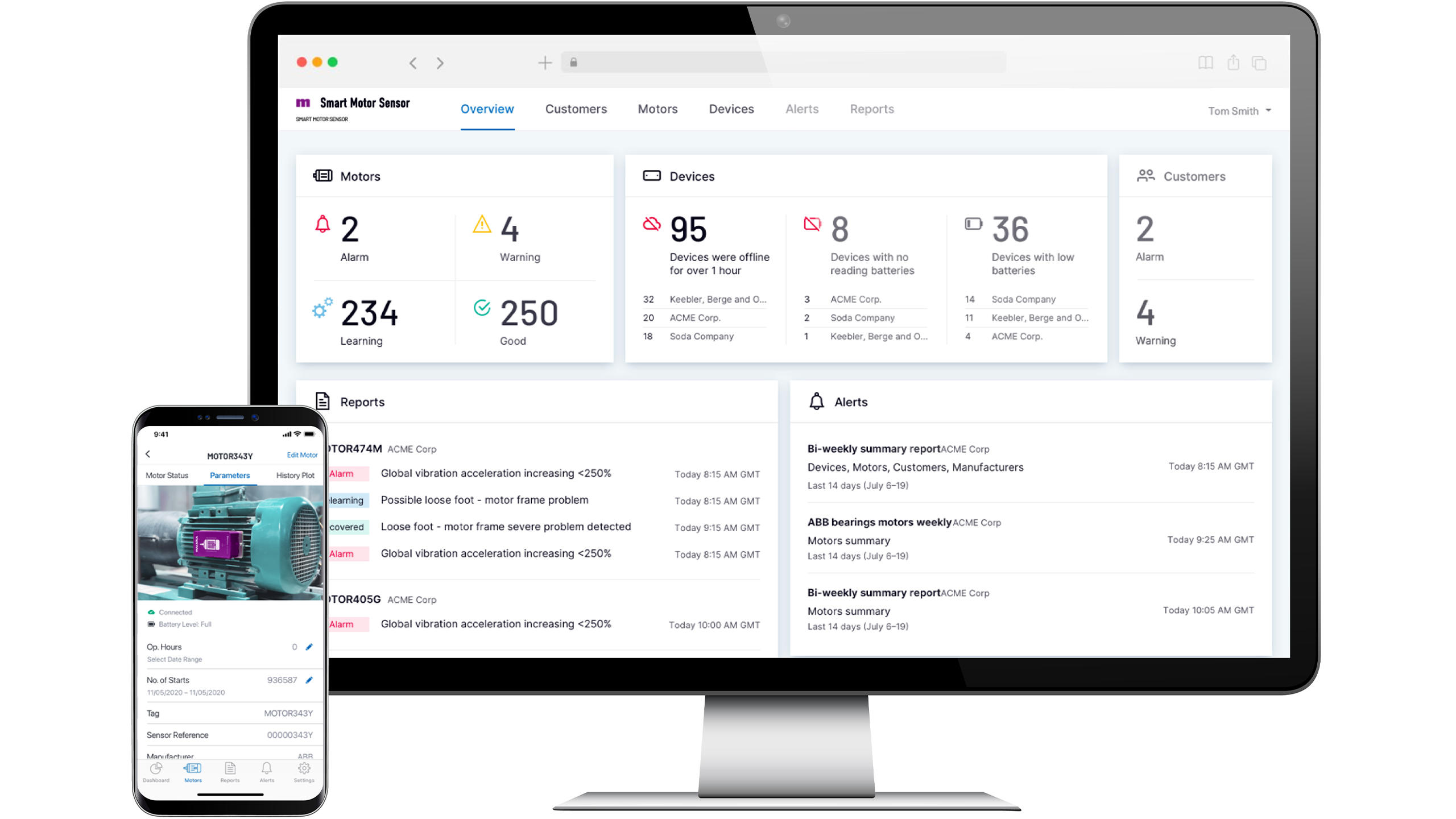

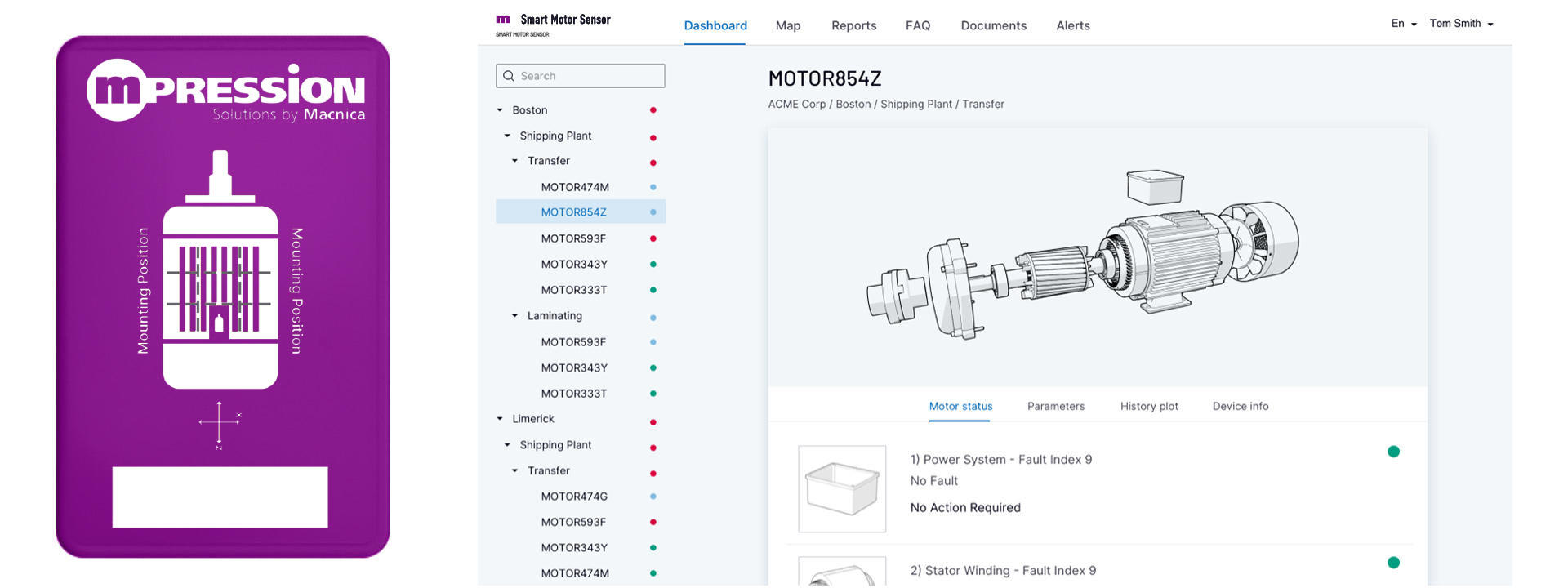

Smart Motor Sensor (Mpression Smart Motor Sensor) is a hardware-cloud integrated remote monitoring solution specialized for low-voltage three-phase squirrel-cage induction motors that can be introduced without specialized knowledge.

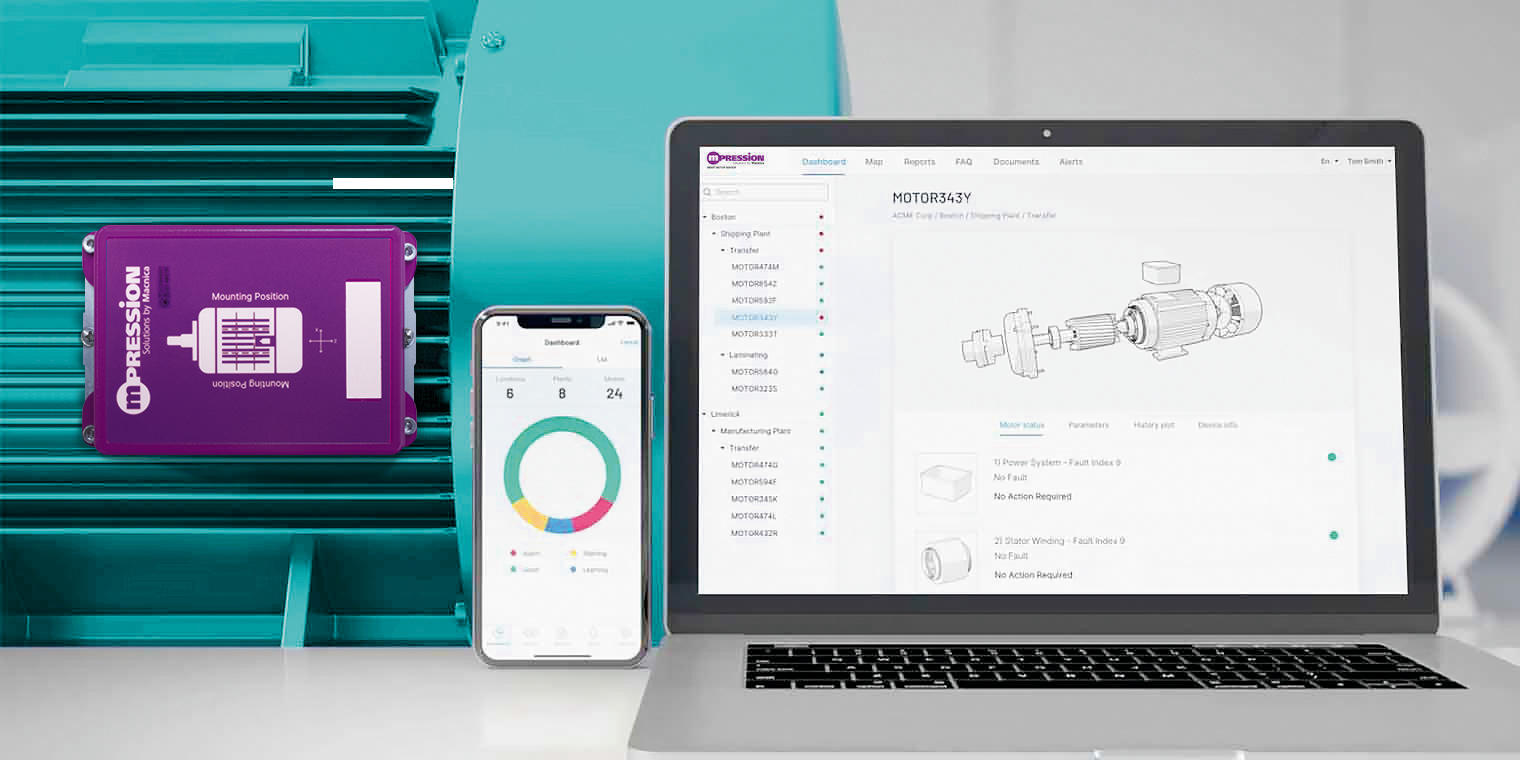

A battery-powered sensor is attached to the cooling fins of the motor, and initial settings are performed using a smartphone app. After the start of use, machine learning by AI will automatically start, and an AI model that detects anomalies will be automatically generated after a certain period of time.

Since the motor status can be checked in real time from a PC browser or smartphone, maintenance can be predicted.

When an anomaly is detected, an alarm is automatically sent via mobile app or email.

Three features of smart motor sensors

- I have a sensor attached to the device and I am collecting data, but I don't know how to use it.

- I don't know how to set the threshold

- 3 years after starting predictive maintenance... it's hard to get to the actual operation

There may be various issues and concerns in realizing motor condition monitoring, abnormality detection, and predictive maintenance. Macnica 's smart motor sensor will solve these problems!

Smart and remote monitoring is possible because it supports Wi-Fi

Real-time status can be grasped

Automatic from data collection to threshold setting and abnormality diagnosis

Because it is a specialized type, it is possible to notify even the location of anomalies and how to deal with them.

Nine abnormal modes that can be diagnosed and detected

| power system | Faults caused by the power system. For example, changes in the impedance of the power cable and loss of phase. |

|---|---|

| Stator winding (insulation diagnosis) | Faulty stator windings. This fault can cause motor current asymmetry. For example, when the impedance of only one phase of the motor changes. |

| rotor | Failures are caused by discontinuities in the moving parts of the rotor, such as the rotor bars and end rings, and weld problems in copper rotors. This problem can occur with motors that start/stop frequently. |

| shaft / balance | The rotor becomes unbalanced due to the deviation of the center of gravity of the rotating part of the motor. For example, a bent shaft, missing balance parts, or dust buildup on the motor fan. |

| Eccentricity (air gap) | The problem is that the starter and rotor are not concentric. In large motors, this can be caused by bending the rotor shaft or tilting the shaft due to poor bearing installation. |

| bearing | Bearing failure due to defective inner/outer rings, retainer, rotating body, or insufficient lubrication. Possible causes include improper installation, improper operating conditions, and current in the bearing. |

| alignment | The alignment between the motor itself and the load side is in a bad state. |

| cooling system | This could be due to a malfunction of the motor cooling system, a blocked ventilation opening, or a stopped fan. |

| mechanical looseness | This is a defect caused by mechanical looseness of the motor. This is caused by the motor not being installed properly. |

Case

Column

Related product

Limited quantity! Trial kit free rental campaign

Kit contents

スマートモーターセンサー /

ダッシュボードライセンス

Install it on your motor,

the actual state of the motor

You can check it on your dashboard!

Please contact us for a trial period.

Please feel free to contact us.

▼ Contact us below ▼