Visual inspection automation by AI

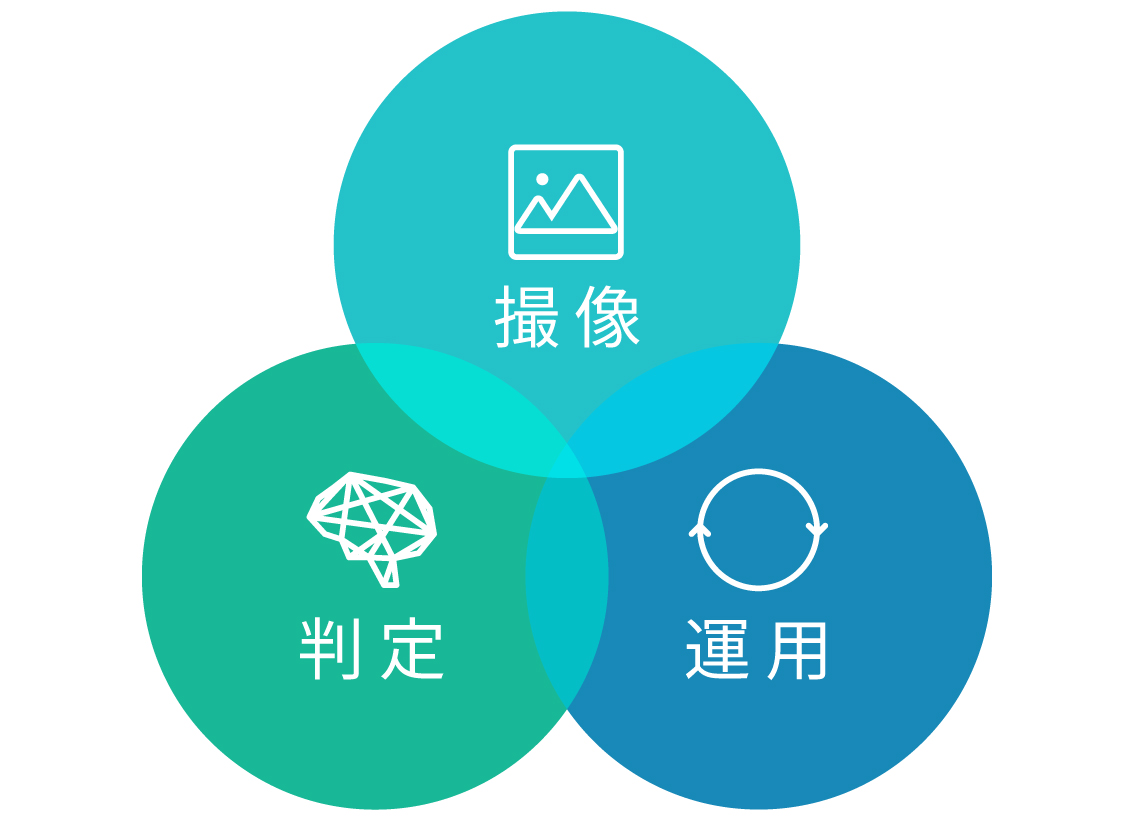

"imaging", "judgment" and "operation"

Integrating three know-how

One stop solution! !

Do you have any of these problems?

I want to digitize and automate the work that depends on individual skills in the inspection process.

It takes a huge amount of time to design feature extraction (parameters) for inspection equipment...

The work of NG classification requires a lot of man-hours for inspectors, and we want to promote efficiency and automation.

Those who have concerns about AI utilization and are at a standstill

Appearance inspection is a very important process to meet high quality requirements from customers and to secure trust.

An increasing number of companies are working on automation with the aim of breaking away from individualized inspection methods.

Behind this is the improvement of imaging technology that replaces the human eye and the dramatic progress of AI technology that replaces the human brain.

In AI in particular, the era has changed from the era in which AI can distinguish things that can be distinguished by the human eye, to the era in which AI can distinguish things that cannot be distinguished by the human eye.

However, although these technological advances have increased the possibility of realizing automation, on the other hand, more specialized knowledge is required, and it has become difficult to proceed with the project with only the human resources of the company.

At our company, we have integrated the three know-hows of "imaging", "judgment", and "operation" that require expertise so that those who are going to work on automating appearance inspection can proceed with the project with peace of mind. We provide a one-stop service from the formulation of an overall plan to operational support.

In addition to automating the appearance inspection process, we analyze the causes of defects using acquired image data, and provide support for quality improvement solutions that identify defects and digitization of the entire manufacturing site.

Three things necessary for Visual inspection automation

AI visual inspection manual BOOK

This is a free material that explains in detail the points to consider: "imaging", "judgment", and "operation", which are the three essential elements for Visual inspection automation using AI!

Visual inspection automation,

Three of "imaging", "judgment" and "operation"

They are closely related.

just one of

Automation is not possible.

Point of Imaging: Building an Environment That Can Detect Defects

Judgment point: Eliminate oversight

Operational points: data management, maintenance

but,

Simply following the points above will not work.

because…

Notes on the imaging phase

Just to take a picture of the target

tend to focus

[Failure example]

The total number of shots is enormous, and as a result, the tact time exceeds the specified limit.

[Solution example]

Succeeded in developing a model that does not miss anything by performing AI learning with an expanded imaging field of view

Notes on judgment phase

A model that detects NG only by the amount of learning

tend to rush to cover

[Failure example]

Accuracy improvement of specific NG detection hits a ceiling

[Solution example]

Succeeded in high-precision AI judgment by increasing lighting on the imaging side and performing specialized imaging for specific NGs that cannot be overlooked.

Points to note in the operation phase

We succeeded in device development and AI model development, but...

[Failure example]

Unable to secure human resources capable of managing and operating AI models, unable to upgrade...

[Solution example]

Succeeded in maintaining the operational level by formulating post-operational workflows in advance, planning countermeasures, and securing human resources.

Issues that may occur in each phase

There is a possibility that it can be solved by complementing each other.

In other words, after holding down each point,

Know-how in “imaging,” “judgment,” and “operation”

We need to consider it comprehensively.

1 Imaging

It is a very advanced technology that makes full use of optics, software technology and image processing technology.

As an example, there are the following methods.

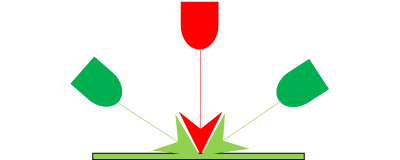

- A method to improve inspection performance by changing the lighting angle and lighting direction

- A technique for reducing reflected light with a modified filter

- Detection method by synthesizing images with different lighting directions

- A method that separates colors for each lighting angle, such as coaxial lighting, ring lighting, and colored lighting, and detects them in batch imaging.

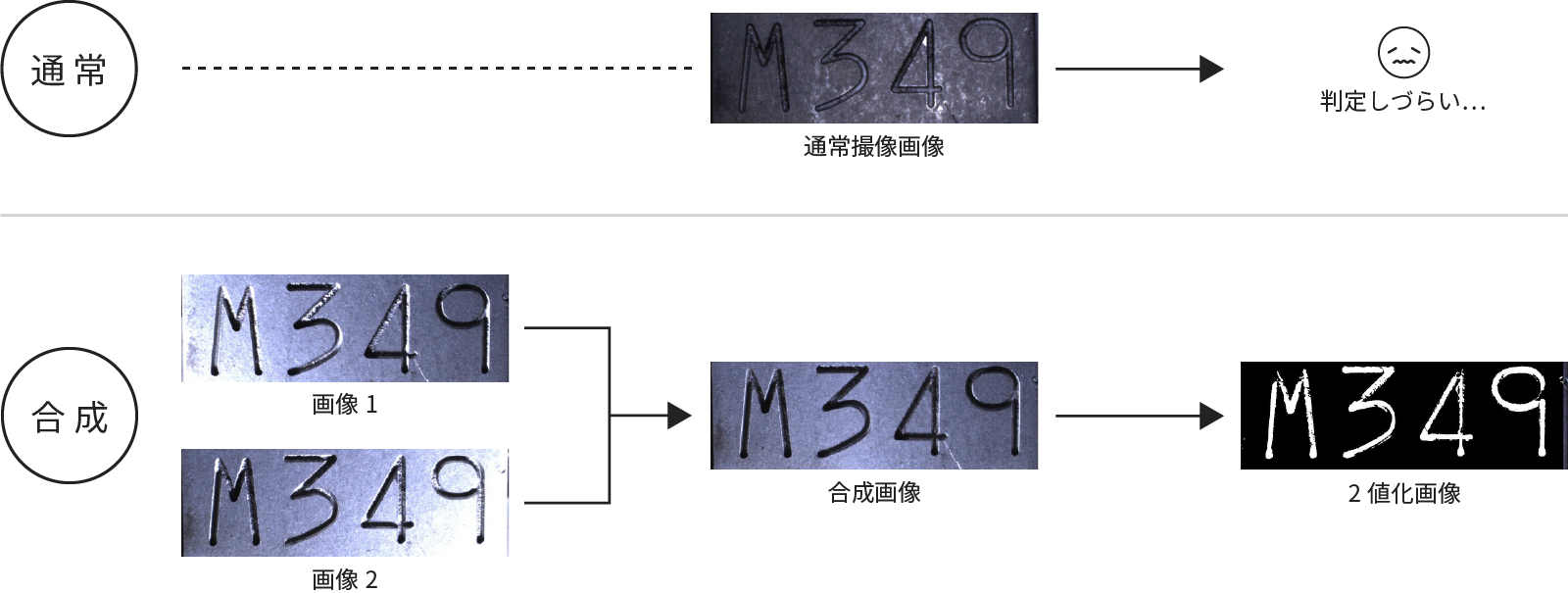

Imaging example 1 Engraved character inspection

Method: Detect by synthesizing images with different lighting directions

It can be seen that even engraved characters, which are difficult to discriminate in normal images, can be clearly discriminated.

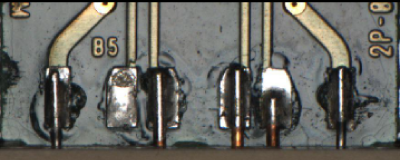

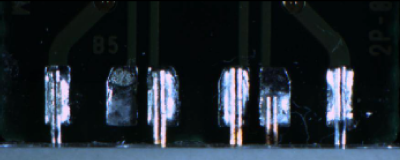

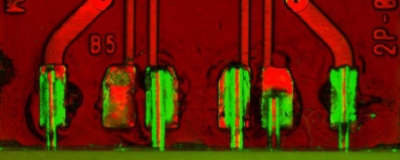

Imaging example 2 Solder inspection

Method: Coaxial lighting, ring lighting, colored lighting, etc. Detect by batch imaging by classifying colors for each lighting angle

Imaging time can be shortened because of batch imaging.

Coaxial illumination image

ring lighting picture

Colored lighting image

Image of colored lighting

≪ Flow of introduction of standard imaging equipment ≫

*The order may change depending on the situation.

|

Inspection standard |

|

| ▼ | |

|

Mass production inspection process |

|

| ▼ | |

|

Imaging |

|

| ▼ | |

|

imaging test |

|

| ▼ | |

|

Equipment introduction |

Using the imaging mechanism created by image inspection, we will manufacture a visual inspection device that meets your needs. |

≪Frequently asked questions about shooting≫

2 Judgment

Here, we will introduce the points of introducing a judgment model by AI.

≪ Inspection method and characteristics ≫

We will introduce the general characteristics of AI image inspection, visual inspection, and conventional image inspection.

It is important to recognize and understand the characteristics of each in order to select the method that fits the problem to be solved.

|

Visually |

AI image |

conventional |

|

|---|---|---|---|

|

Ease of design |

― | △ | × |

|

with roses |

〇 | 〇 | × |

|

distinguishing features |

〇 | 〇 | △ |

|

consistency of judgment |

△ | 〇 | 〇 |

|

Reliability of operation |

△ | 〇 | 〇 |

|

processing speed |

× | △ | 〇 |

|

exact measurement |

× | × | 〇 |

Inspection examples for which AI image inspection is easy to apply

Occurs with existing imaging tests

Reduction of gray zone (suppression of over-detection)

Dirt and scratches that cannot be dropped into rule-based inspections

Classification and sorting based on differences in characteristics, such as distinguishing between

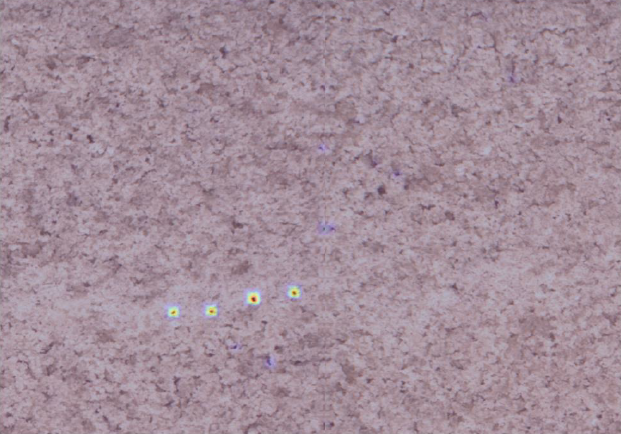

Application example of AI image inspection Inspection of workpieces with uneven patterns

This is a foreign matter inspection for material-based workpieces that are difficult to distinguish with the human eye.

With current AI technology, it is possible to detect foreign objects with a high degree of difficulty like this.

Inspection object

AI reaction point

≪ Flow of judgment model construction ≫

|

sample image |

After concluding a non-disclosure agreement, we will keep sample images (OK/NG). |

| ▼ | |

|

Data preprocessing |

Consider the data structure by combining dozens of candidates for image cropping, reduction, binarization, etc. |

| ▼ | |

|

study |

Start learning by selecting tools, selecting networks, examining various parameters |

| ▼ | |

|

inspection |

We verify the accuracy of the AI model built by learning, consider it, and select the optimal model. |

| ▼ | |

|

Accuracy report |

We will report the accuracy of the developed AI model |

≪Frequently asked questions about AI judgment≫

3 Operation

In the operation phase, we will perform AI retraining to improve the accuracy of the judgment model.

Since AI relearning requires specialized knowledge, Macnica supports customers by providing AI operation services.

|

operational data |

Full-scale collection of image data, which was scarce at the PoC stage |

- AI Operation Service -

|

| ▼ | ||

|

AI model |

AI learning using operational data |

|

| ▼ | ||

|

AI model |

Implement the developed AI model |

|

| ▼ | ||

|

Accuracy verification |

Link the results of regular human inspections and AI judgments |

|

| ▼ | ||

|

Relearn |

Relearn images that AI misses/overdetects |

How to proceed with the Visual inspection automation project

When starting a project, Macnica first formulates an overall plan to address the client's unique challenges.

We also provide a variety of services at each phase to enable our clients to proceed with their projects with peace of mind.

|

How to proceed with the project |

service |

|

|

-Phase 1- |

Grasping the current situation / Creating a plan / Examining cost effectiveness / Creating a work flow / Scrutinizing the estimate |

Consulting Services |

| ▼ | ||

|

-Phase 2- |

Examination of imaging environment (camera, lighting, image size, tact time) / simple equipment estimate / rough estimate of operation equipment |

・Imaging verification service |

| ▼ | ||

|

-Phase 3- |

Required specifications / business flow / functional requirements / system configuration / data storage system / production linkage system / quotation |

Operation phase requirements definition service |

| ▼ | ||

|

-Phase 4- |

Imaging device development / transportation system / operation system introduction |

・AI model development service |

| ▼ | ||

|

-Phase 5- |

Operation image data collection / AI model development / AI model implementation |

・AI operation service |

Beyond automation

Manufacturing industry DX starting from Visual inspection automation

Various realizations can be obtained from the data (facts) obtained by visual inspection.

for example…

If there is data with many defects

→ Isn't it better to investigate and improve the cause of defects that occur in the previous process? the realization that

If there is data that the inspection quantity itself is decreasing

→ If the number of production changes, wouldn't it be better to establish a personnel shift? the realization that

→ Actually, if it turns out that there were many short stops, wouldn't it be better to do CBM? realization that

Awareness obtained from the data obtained in this way will be a stepping stone toward the realization of DX.

I know how to proceed! Seminar video

A seminar video showing how to proceed with Visual inspection automation is now available!

I want to hear more about the Visual inspection automation project! If you are interested, please listen to it.

With the cooperation of imaging partner Shindenshi Co., Ltd. and AI partner CEC Co., Ltd., we are delivering it in four parts.

- [Introduction] Steps for visual inspection optimization

- [Imaging] The most important step for automating visual inspection, the secret of building an imaging environment

- [AI Utilization Edition] Appearance Inspection x The Forefront of AI ~Keep an Eye on AI's Actual Values and Possibilities~

- [Automation, Beyond] The path of factory DX starting from the optimization of visual inspection