Digital twin that creates "three movements"

One step ahead of "reproduction in virtual space"! "Moving 〇〇" created by utilizing digital twins

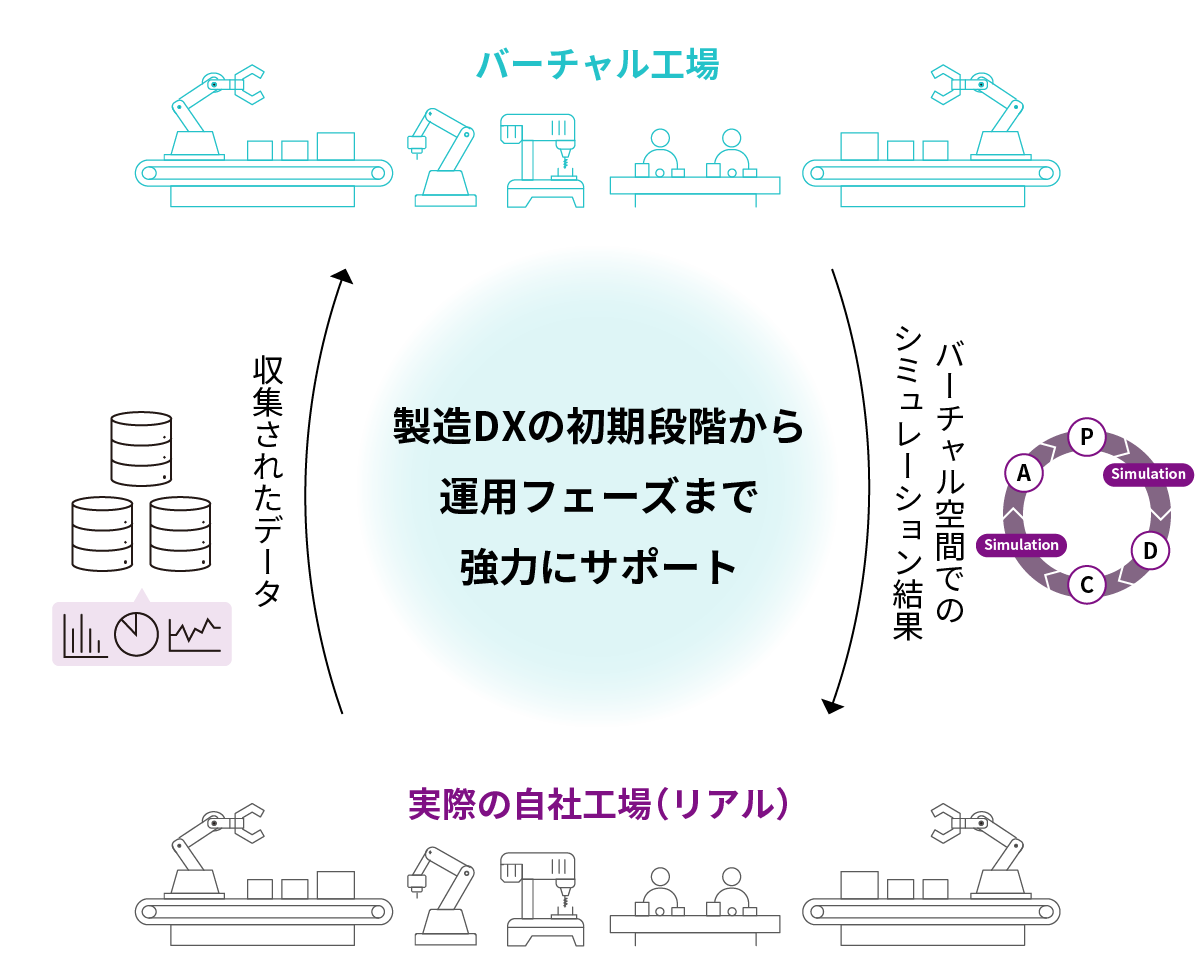

In promoting Digital Manufacturing, using a digital twin to obtain a "moving" virtual factory is an effective means. In addition to being used from the beginning of the project, it will be a strong partner until the realization of "sustainable Digital Manufacturing". However, the true value of the digital twin does not stop there. Introducing the real ability to create "three movements" that accelerate Digital Manufacturing.

What are "three movements"?

1

"Moving" virtual factory

Visualization of issues

2

The site "moves"

Share the future of work

3

Management "moves"

A concrete DX project

1. Visualization of issues “moving” virtual factory

A digital twin reproduces your factory in a virtual space, realizing "visualization" of the state of the factory and issues that are bottlenecks.

Furthermore, it is possible to try as many times as you like, improving planning accuracy and optimizing processes/resources. In other words, the digital twin in promoting Digital Manufacturing can help you efficiently rotate the PDCA cycle from the initial stage, and can support your Digital Manufacturing promotion as a powerful partner that plays an important role in the operation phase.

It is also possible to fuse virtual and real factories after continuing to use digital twins from the early stages. In that case, we will realize "sustainable Digital Manufacturing" that collects and analyzes the data necessary for improvement and maintenance in real time and feeds back the optimal solution.

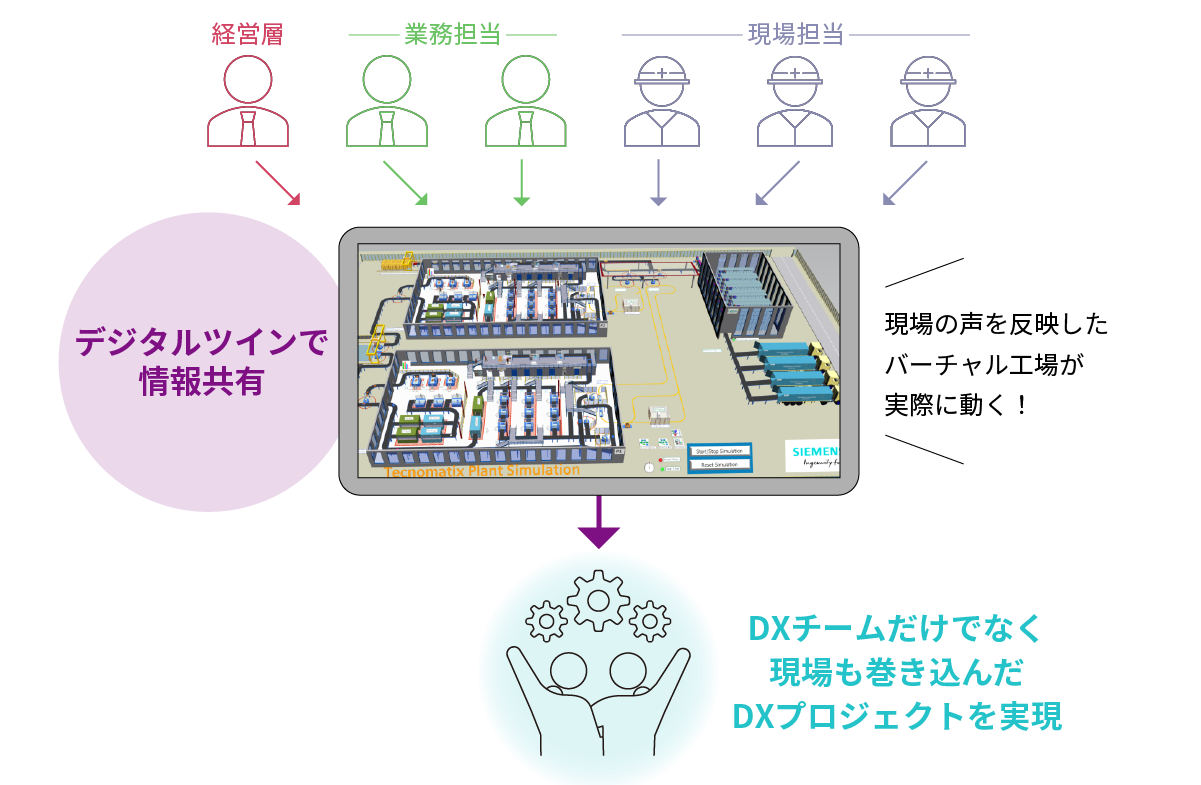

2. Sharing the future of jobs where the workplace "moves"

Digital twins are excellent not only as simulators, but also as communication tools.

One of the big “walls” in promoting Digital Manufacturing is cooperation with “sites” such as other departments and related departments. An effective way to remove that "wall" is to share the future that "actually works".

By sharing how the simulation will change the factory and how the movement of people will change, feedback from the field will be generated, and from negative voices such as "Why are we proceeding with DX?" You can change it into a positive voice that says, "What?"

Furthermore, if it is simple feedback, it is possible to immediately perform simulations in a shared space, and it is also possible to realize a "DX project involving the site" at once.

3. Concrete DX project for management to “move”

Simulations using digital twins are also effective in approaching management.

Concerns regarding the promotion of Digital Manufacturing can be considered as many times as possible in advance at the lowest cost and in the shortest period of time, giving management the impact of "project specificity" and "visible project" on investment decisions. I can.

Also, by showing a virtual factory that actually works like the actual site, it is possible to overcome the big barrier of "cost-effectiveness", which is one of the judgment criteria for management.

From there, proactive communication is born, and it is the "digital twin" that has the potential to create the beginning of "real Digital Manufacturing" where the <DX promotion team>, <on-site>, and <management> work together. .

*After applying, you will be redirected to the video list page.

Related services

Macnica also supports various individual themes.

Document

Other materials

Explore other approaches

Digital Manufacturing starting from health checkup

Manufacturing process innovation starting with digitization