From management relying on human senses to diagnosis by AI

Aiming to optimize motor maintenance with predictive maintenance solutions

--Rengo Co., Ltd.

This is a customer testimonial about the adoption of the "Smart Motor Sensor" by Rengo Co., Ltd. In order to optimize the maintenance of papermaking machines, which are extremely important in the paper manufacturing process, the company has introduced quantitative management and evaluation using a motor predictive maintenance solution.

Participating members of this project

Rengo Co., Ltd.

- Mr. Naoya Dozono, Deputy Manager, Digital Promotion Department, Papermaking Technology Development Headquarters, Papermaking Division

Macnica

- Ultima Company Analog Solutions Division 1

Shiro Enohara, Product Solutions Division, Product Marketing Department

- Task

-

- Variations in maintenance due to human senses

- Usage

-

- Papermaking machines play an important role in the papermaking process

- effect

-

- AI-based diagnosis enables quantitative management and evaluation

- You can tell "this is wrong" rather than "somewhere wrong."

Issues at manufacturing sites

Dozono: At manufacturing sites, it is necessary to prevent sudden equipment stoppages and ensure stable equipment operation. To achieve this, maintenance is extremely important. Of course, it is important to check with the five human senses, but there are also some areas where variation occurs due to experience and skill.

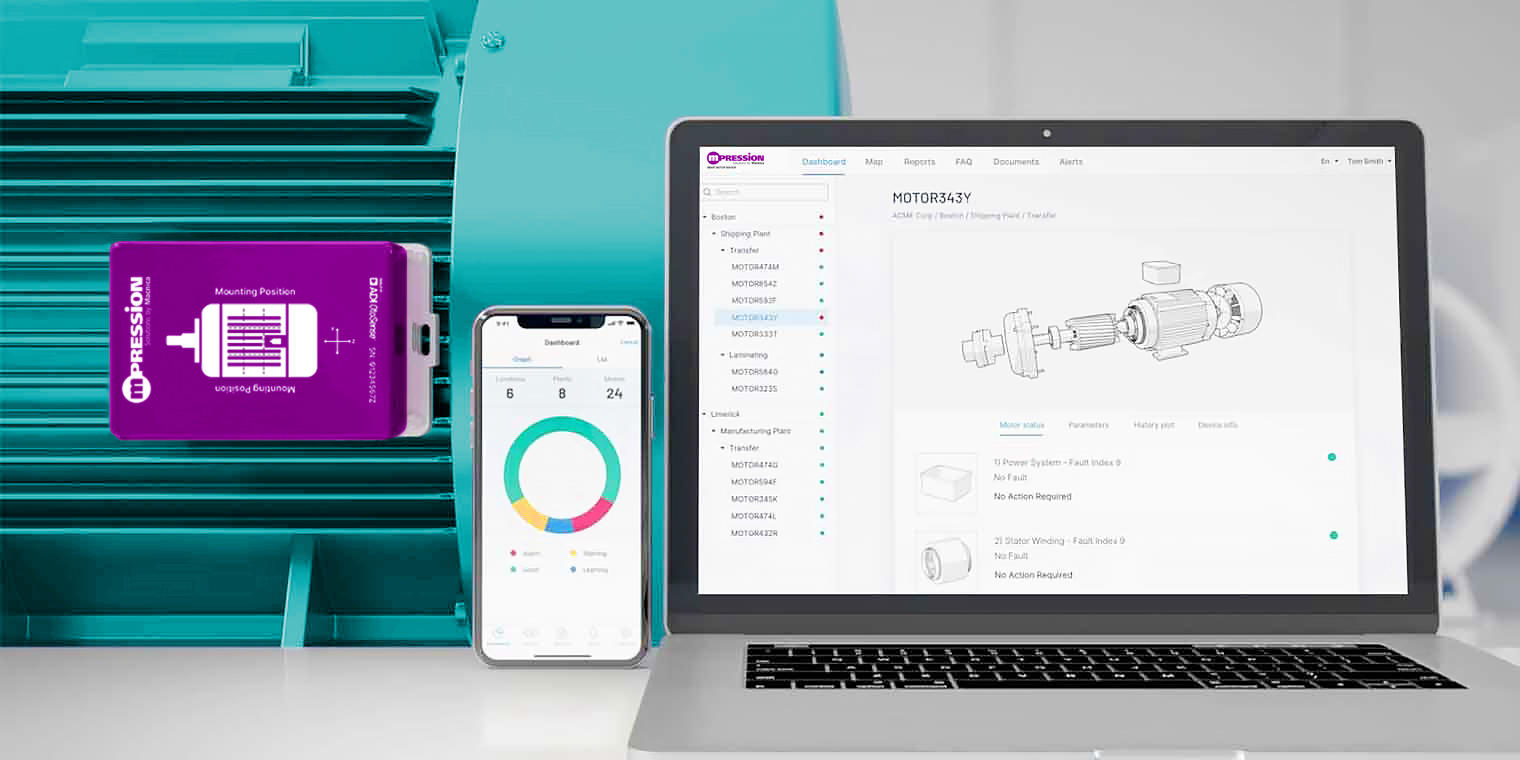

The "Smart Motor Sensor" (SMS) enables quantitative management and evaluation through AI diagnosis, so we are promoting the use of SMS in order to solve these issues.

Introduction of "Smart Motor Sensor"

Dozono: We are currently introducing "SMS" mainly to paper mills. In the paper making process, there is a process called "paper making" where water-diluted paper stock is poured into the machine. In this process, the papermaking machine is a very important piece of equipment. This machine uses a large rotating body to transport the paper, and a motor is used to drive this roll.

For electrical equipment maintenance personnel, the "SMS" is very attractive because it specializes in monitoring the condition of not only bearings but also electrical abnormalities in motors. When something abnormal occurs with a motor, it has the great advantage of not just letting you know "something is wrong," but "this is what is wrong."

Looking ahead

Dozono: In the event that an abnormality should occur with the motor in the future, I hope that "SMS" will contribute to conservation efforts by notifying us of the abnormality before it leads to major trouble.

Additionally, the Company equipment uses a large number of high-voltage three-phase motors, so we would be grateful if a product compatible with these motors were available.

Rengo Co., Ltd.

- Business

- Manufacture and sale of paperboard, corrugated board, corrugated boxes, folding cartons, and other paper products

- Founded

- 1909

- Number of Employees

- Consolidated: 23,389 employees Non-consolidated: 4,345 employees (as of March 31, 2024)

- website

- https://www.rengo.co.jp/

PRODUCT/SERVICE

Click here for products and services related to this case study

Mpression Smart Motor Sensor

Predictive maintenance service specialized for low-voltage three-phase squirrel-cage induction motors

CONTACT

Please feel free to contact us with any inquiries regarding this case study or product implementation.