In recent years, the term “smart factory” has become popular, and some people may have tried technologies such as IoT and AI.

Under these circumstances, there are many cases where the use of digital technology itself becomes the goal and the introduction of tools becomes the goal.

The use of digital technology is nothing more than a "means to realize what you want to achieve at the production site".

So what is the essence of the use of digital technology?

In this article, I would like to introduce two themes that I would like you to consider first when promoting a smart factory: "sophistication of improvement activities at production sites" and "data accumulation with an eye to DX."

1. Sophistication of improvement activities at production sites

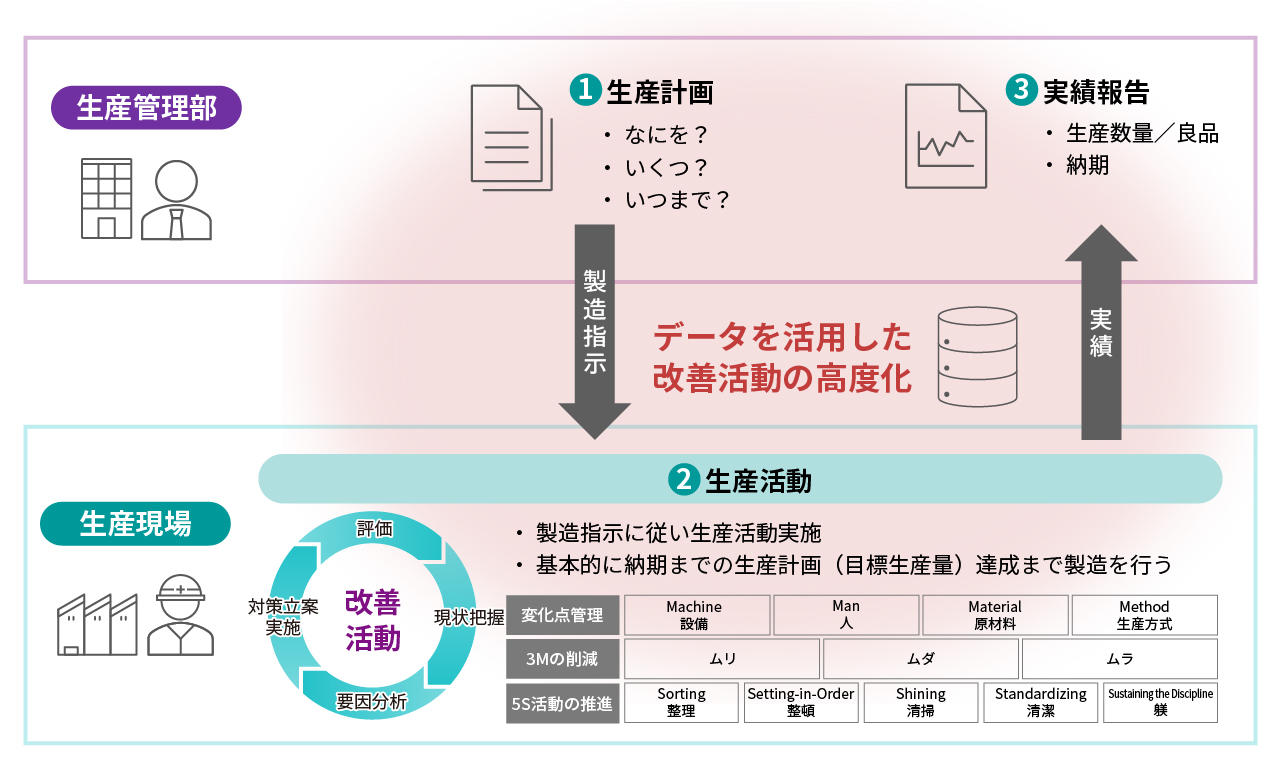

The basic role of the production site is to produce the target quantity planned by production management with high quality by the delivery date. In order to achieve this efficiently, continuous improvement activities are required.

The method of carrying out improvement activities has been established in the long history of manufacturing activities. in particular,

・Three things: “overburden,” “waste,” and “unevenness.” M. reduction of

・"Organization (Sorting), tidy up (Setting-in-Order)""cleaning(Shining)”, “Cleanliness (Standardizing), Discipline (Sustaining the Discipline)” S. Promotion of activities

・Production Four The element called "people (man)""machine(Machine)""material(Materials)""Method(Method)”, change point management, etc.

Through Kaizen activities, many manufacturing industries identify and reduce "losses" that impede production efficiency, and continue better manufacturing activities.

The purpose of utilizing digital technology is the starting point of improvement activities and maximizing production efficiency, which is the same as the purpose of the activities we have been working on so far.

The difference from conventional improvement activities is that the improvement activities up to now can be realized more easily, quickly, and with higher accuracy by utilizing digital technology. We believe that this is the essence of the use of digital technology.

2. Data accumulation for DX

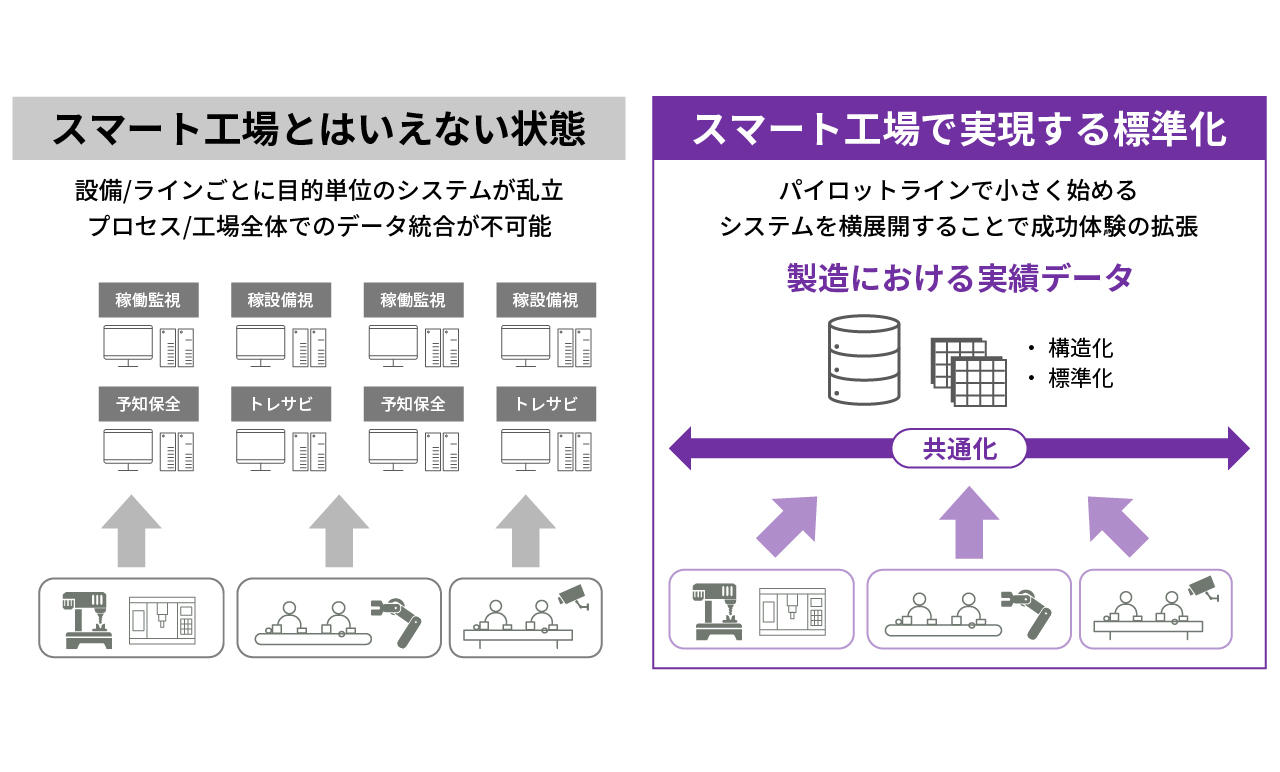

As expectations for DX are increasing in companies, not only the enhancement of conventional improvement activities, but also transformation that anyone can understand is required. In order to realize such DX, accumulated data of the production site is necessary as a major premise.

In the supply chain, DX in the production phase tends to be delayed. I think that there is a background that it is difficult to acquire data because there are many records by people and old equipment data. In fact, I think that there are many people who say that "the data of the production site is accumulated". However, in most cases, the data of the production site is accumulated in a state divided into units of process and purpose, so the divided and accumulated data can be used to get a bird's-eye view beyond the process and line. However, it is difficult to analyze the entire factory.

In the realization of DX, it is important to accumulate "data shared throughout the factory".

There are two major requirements for a smart factory.

(1) Sophistication of improvement activities at production sites

② Based on the data accumulated at that time DX Realize with a common data structure in anticipation of

For those who are going to promote it from now on, and those who are already working on it, why don't you consider these two themes before proceeding with the project?

in conclusion

Based on this idea, we are supporting the promotion of smart factories for everyone in the manufacturing industry in various genres.

In the video below, you can learn how to think about line production efficiency and loss analysis and how to obtain worker status without burden.

We introduce specific initiatives. Please refer to it.

DSF Cyclone Product Introduction

Supporting quick start & quick win of smart factory

"DSF Cyclone" connects manufacturing results and production plans with structured data to realize a "highly productive factory".

If you are interested, please refer here.