This article is recommended for those who

- Those who are considering and introducing data collection and utilization of factory equipment

- For those interested in Macnica 's data collection solutions

How long does it take to finish reading this article

5 minutes

Introduction

Hello. I'm Sakuraba from Macnica Solution Development Division!

In our first tech blog: Trying to turn a small Macnica factory into a smart factory (Part 1), we introduced our factory demo machine.

This time, the second in a series of five articles, we will introduce a data collection solution using this demo machine. .

What is a data collection solution?

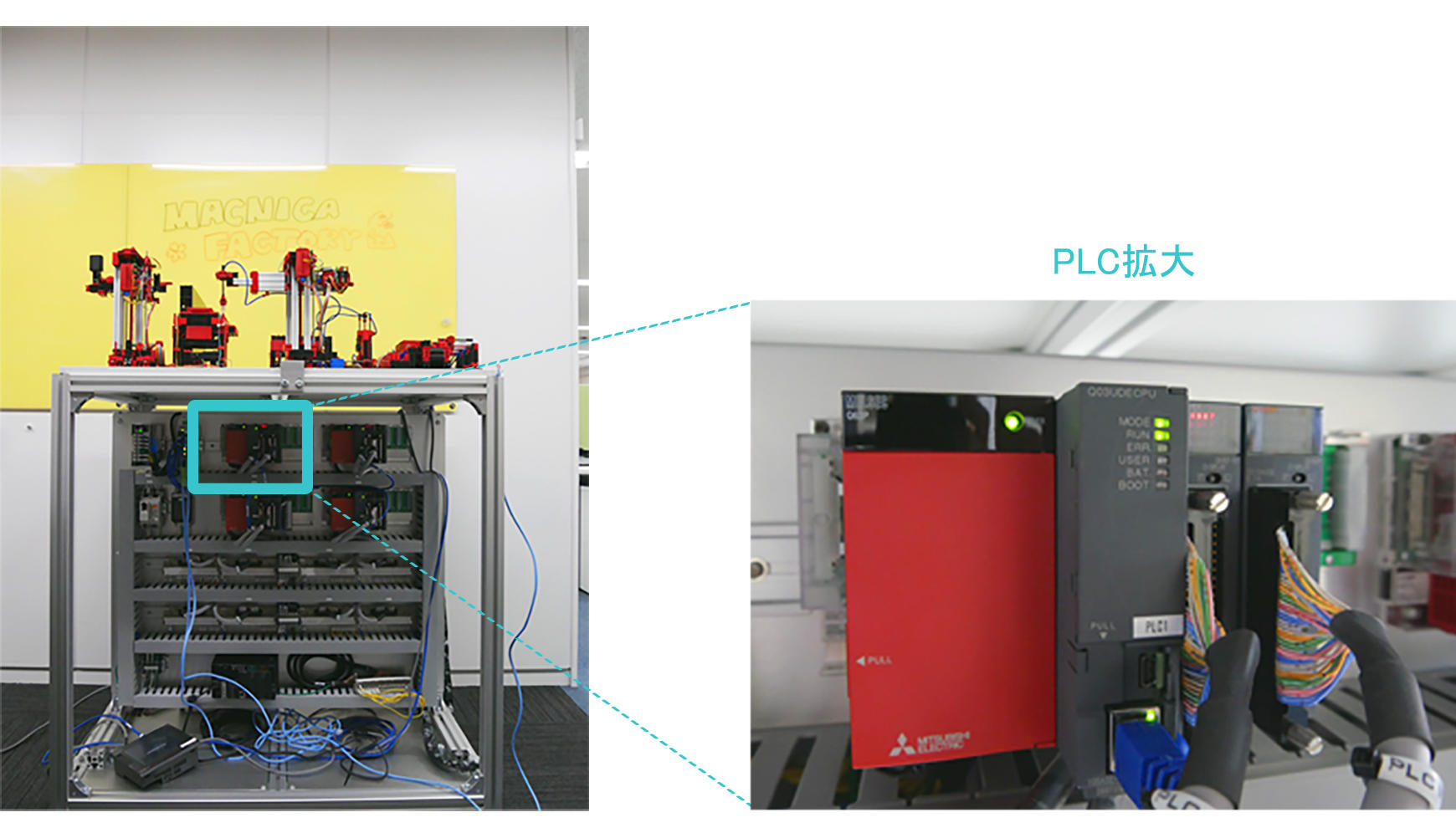

PLCs (Programmable Logic Controllers) are used as control devices for various devices in actual factories.

The main role of a PLC is to control equipment, and it has the input/output functions necessary for that control.

Input/output functions vary depending on the connected sensors and switches.

Information on the operating status of equipment such as ON/OFF information of switches, position information of equipment, temperature, voltage, current, etc. is aggregated.

One of Macnica 's data collection solutions is to extract and utilize this data efficiently.

let's get the data out

Now let's actually retrieve data from the PLC!

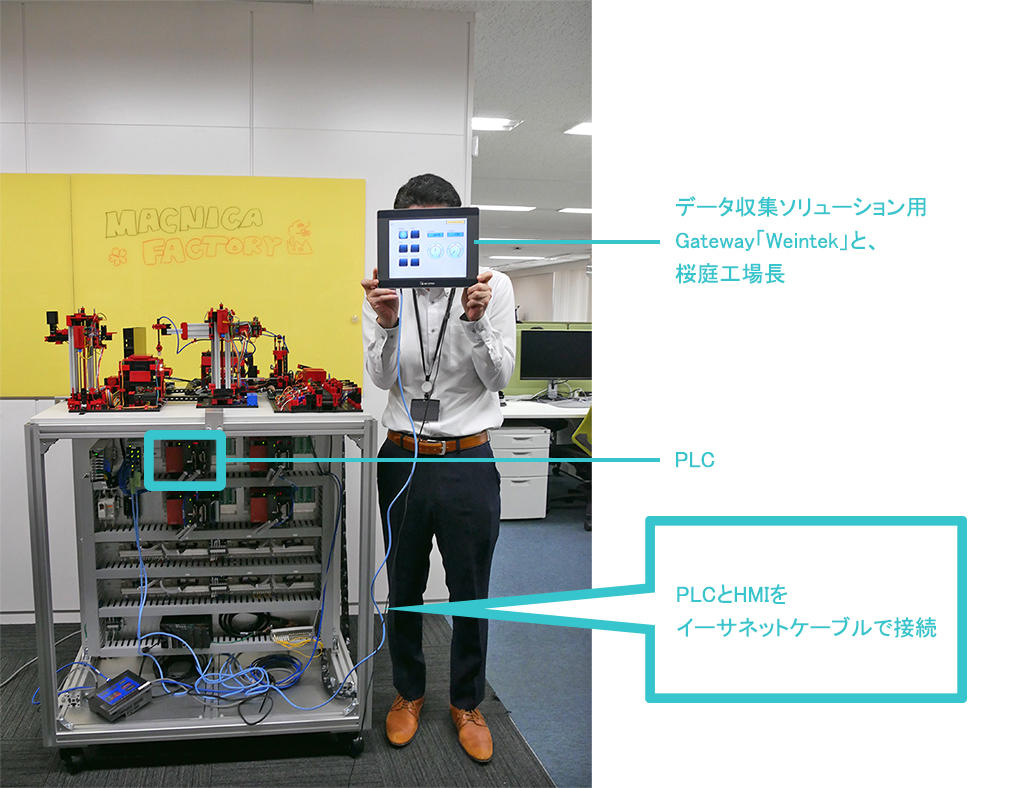

We use Gateway made by Weintek for retrieving data.

Since this Gateway for data collection solution is equipped with an HMI (screen display), it is possible to separate the information you want to see on site from the information you want to see on the management site.

In addition, since this product supports MQTT and OPC-UA communication protocols, it is easy to connect to clouds such as AWS and build networks in factories.

Four PLCs are connected to the factory demo machine, but this time we will try to retrieve data from the PLC controlling the warehouse.

The procedure for retrieving data is roughly as follows.

- Check the address of the data you want to read from the target PLC (This time, retrieve the position information of the crane in the warehouse)

- Write PLC information and connected network information from PC to Gateway for data collection solution

- Make settings for visualizing read data on HMI of Gateway for data collection solution

- Connect the gateway for data collection solution to the network where the PLC is connected with an Ethernet cable

that's all.

Only this.

Very easy, isn't it?

With this procedure, the environment for checking the retrieved data on site is ready.

Now let's watch the video that shows how the data is actually retrieved.

Toward utilization of smart factory data

In this article, we introduced the method of extracting data from the PLC, which is one of the data collection methods that are the key to smart factories.

There are other methods of collecting data, such as the use of high-sampling data loggers and the collection of image data using cameras, but I would like to introduce them on another occasion.

Next time, I will focus on how to utilize the acquired data.

In addition, the content of our solution is described on the following page, so please check it together with this article.