Challenge the “wall” of Japanese manufacturing DX! Macnica begins collaboration with overseas top runner Orange Leaf to support in-house DX production ~ Experience-first, speeding up DX human resource development ~

Macnica (Headquarters: Yokohama City, Kanagawa Prefecture, President CEO: Kazumasa Kazumasa Hara, hereinafter referred to as Macnica) has announced that Orangeleaf Consulting (Headquarters: Malaysia, CEO: Ellice Ng Pui San, hereinafter referred to as Orange) will promote DX in the manufacturing industry. We are pleased to announce today that we have agreed to form a business partnership in DX consulting with Leaf) and will begin our collaboration.

(From left) Atsushi Sato General Manager of Innovation Strategy Business Division, Macnica

Orangeleaf Consulting CEO Ellice Ng Pui San, co-founder and managing partner Tim Hendricks

■“Lost 10 years” Why isn’t Japan’s manufacturing DX progressing? The challenge is to foster a DX culture and develop human resources.

The wave of "Industry 4.0" (Fourth Industrial Revolution), which was born in Germany in 2011, has greatly shaken the Japanese manufacturing industry. Many companies have been calling for "DX (digital transformation) in the manufacturing industry," and have established DX promotion departments and managers and made investments. DX is a strategic initiative to accelerate organizational growth, improve operations, and deliver value to customers through the adoption and integration of digital technologies. However, there are many cases where changes in the culture/mindset of management and business departments, who are the original promoters, have not caught up, creating walls within the company and causing problems for those in charge of promotion. Furthermore, in Japan, the quality and quantity of human resources capable of cross-organizational business reform and project management linked to systems lags behind countries overseas, creating a barrier in terms of securing human resources. Masu. Behind the ``lost decade'' in manufacturing DX are the issues of ``corporate transformation and systems not being aligned'' due to differences in culture and mindset between departments in DX, and a lack of DX human resources. I am.

■There is no true DX without in-house DX production. Promote self-driven DX with tools to develop DX human resources across the company.

In the field of manufacturing DX, Macnica has provided support for approximately 350 cases using Digital Synergy Factory * 1. For the Company, DX means ``utilizing cutting-edge digital technology to fundamentally reform business models and operations.'' What's important is "experience first," in which you first experience a new business process, and "trial and error," in which you brush up on the content based on that experience. Most manufacturing workplaces have their own challenges, and it is hard to find a way to solve them. There are times when we need to review business models and processes from scratch, but first we try them out and think about them as we make changes. Since speed, flexibility, and response tailored to the situation are important, it may not be possible to achieve this by relying on external IT vendors each time. In-house production is the key to success or failure in DX. We believe it is important to develop in-house leaders who can cross departments and organizations and design business processes by working backwards from the "value" provided to the market and customers.

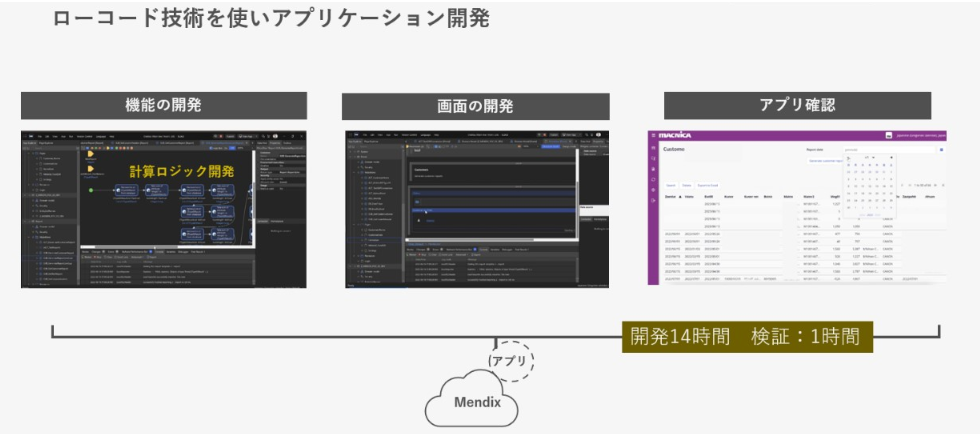

Therefore, Macnica focused on the use of low-code tools. Even if you don't have coding knowledge, you can participate in projects that improve on-site business processes, creating a common language within your company with the IT department. By formulating ideas based on low-code and repeating trial and error with experience first, business departments and IT departments can communicate with each other to promote innovation. This is the speedy and sustainable manufacturing DX envisioned by Macnica. In order to make this initiative a reality and take the first step, Macnica has been providing an accompanying DSF-low-code development support service (Mendix * 2), but now we have welcomed a knowledgeable partner to further expand our efforts. We have decided to accelerate Digital Manufacturing support services.

■About the business partnership ~ Breaking through the DX barrier with Orange Leaf, the world's top runner ~

Macnica chose Malaysia's Orange Leaf as its partner. In DX consulting using low-code, we have over 10 years of experience implementing DX in 100 projects in manufacturing, insurance, retail, etc. in Europe, Singapore, and Malaysia. Ultimately, we aim to enable our customers to promote DX themselves, and we provide support from consulting to human resource development and organizational building. From medium- to long-term planning for in-house DX, support for agile application development using platforms, provision of information on cutting-edge technology for operational improvements, and in-house product owners and low-code development personnel. We provide total support for the phases necessary for in-house DX production, up to the training of employees. Utilizing best practices, we will work with Macnica to contribute to the promotion of DX in the Japanese manufacturing industry.

<Details of the partnership>

1. Formulation of mid- to long-term DX in-house production (App Factory) roadmap for individual customer projects, business improvement/new service planning

2. Agile web and mobile application development support based on “Mendix”

3. Developing future DX human resources (product owners, scrum masters, engineers, etc.)

■Comment from Orange Leaf CEO Ellice Ng Pui San

“the Company are honored to work with Macnica, a leader in technology solutions in Japan. We look forward to contributing to the success of our clients in the manufacturing industry and driving meaningful digital transformation. We aim to leverage technology to innovate the way the enterprise software industry thinks and acts.Our ultimate goal is to achieve bold goals and innovate the way people think and act.Manufactured in Japan It is an important part of the economy and is recognized as a major player, especially in sectors such as automobiles, electronics, machinery and precision machinery.”

*1: Digital Synergy Factory is a general term for Macnica 's solutions/services that accelerate digital transformation (DX) in the manufacturing industry. We will guide you through the process of formulating an executable roadmap based on global best practices, implementing quick experiences that focus on changing the minds and behaviors of those involved, and implementing operations to achieve your goals.

Click here for details: https://www.macnica.co.jp/business/ai_iot/

*2: Click here for details about Mendix

https://www.macnica.co.jp/business/ai_iot/products/service/136982/

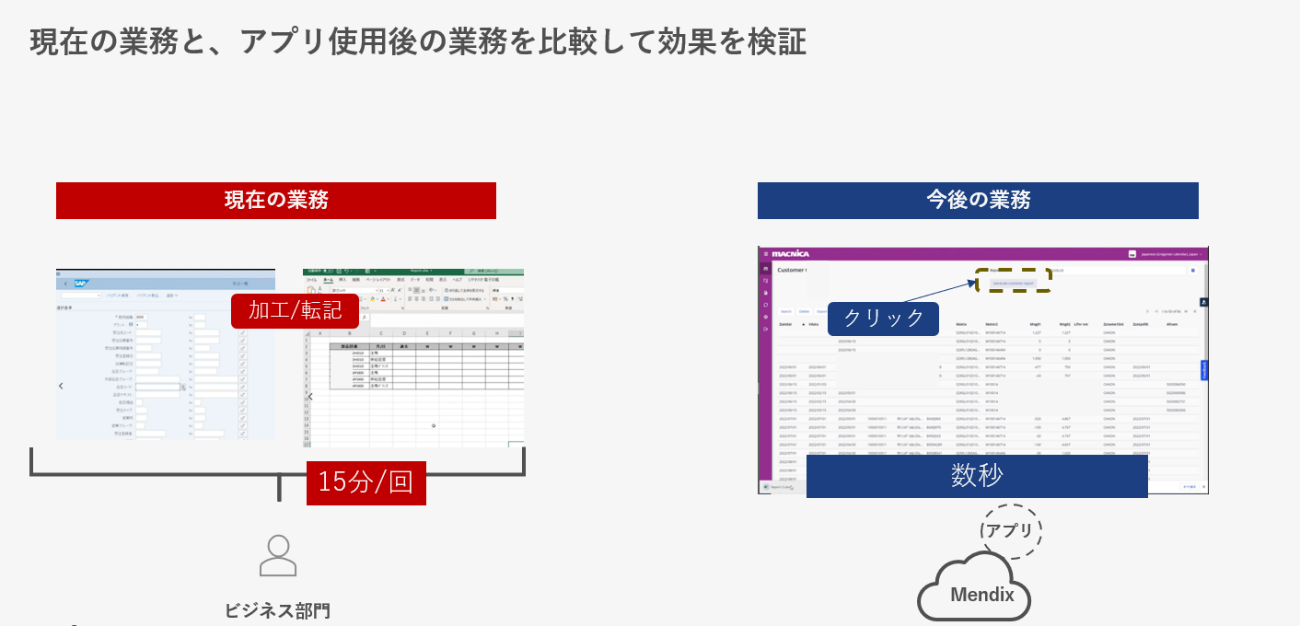

■Example of DX “Experience First” using low-code tools

(A Macnica employee with no coding experience tried it.)

In the semiconductor business, which is Macnica 's main business, sales staff use data output from ERP and Excel to quickly and accurately provide delivery dates to some customers in accordance with customer circumstances. There was a situation where it took minutes/times to create it. Therefore, we planned to develop an application to improve business operations. We developed the app using low code with support from Orange Leaf. As a result, it took a total of 14 hours from business analysis to application development and experience of business improvement effects. Thanks to this app, work that used to take 15 minutes each time now takes only a few seconds, and we have achieved amazing work efficiency. As a result of this experience, further DX business transformation themes for the business division were proposed one after another.

■About Macnica 's smart manufacturing business

Macnica also provides DX support for the manufacturing industry based on the technological capabilities it has cultivated as a semiconductor trading company and its experience in implementing cutting-edge technologies such as AI and IoT. In the future, as DX accelerates in the manufacturing industry, security issues will also emerge. Macnica is also introducing the world's most advanced technology in the security field to Japan. Japan's manufacturing industry faces many unique challenges. Macnica will work hard to create new business opportunities and develop society by listening closely to customers' concerns, discovering issues together, and promoting DX.

[Click here for inquiries regarding this matter]

Macnica Digital Industry Division Person in charge: Tone

Tel: 045-470-9188

e-mail: consulting-iot@macnica.co.jp

*Company names and product names mentioned in this text are trademarks or registered trademarks of Macnica and each company.

*The information published in the news release (including product price, specifications, etc.) is current as of the date of announcement. Please note that the information may be subject to change without prior notice.

About Orangeleaf Consulting

Orangeleaf Consulting is a pioneering digital transformation consulting company based in Malaysia. We help organizations embrace innovation and remain flexible in an evolving world of technology. Our mission is to enable effective transformation, and we specialize in advanced technologies, especially low-code solutions, providing a fast and effective approach to application development and process improvement. And we believe in going beyond just technical solutions to driving meaningful cultural change within organizations, fostering innovation, and building sustainable success.

Please see here for the detail. https://www.orangeleaf.com.my/

About Macnica

Macnica is Service & Solution Company that handles the latest technologies in a comprehensive manner, with semiconductors and cyber security at its core. With operations in 81 locations in 23 countries/regions around the world, the company is leveraging the technical capabilities and global network it has cultivated over its 50-year history to discover, propose, and implement cutting-edge technologies such as AI, IoT, and autonomous driving.

About Macnica: www.macnica.co.jp

<Inquiries from the press regarding this matter>

Macnica://www.macnica.co.jp

Public Relations Office Miyahara E-mail: macpr@macnica.co.jp

Macnica Building 1, 1-6-3 Shin-Yokohama, Kohoku-ku, Yokohama 222-8561