Due in part to the coronavirus pandemic and advances in digital technology, demand for online shopping is expanding and the volume of logistics transactions is on the rise. On the other hand, a lack of manpower is an issue at counters that receive shipments, and "measuring for charge calculations" is a manual and time-consuming process. As the working population decreases, there is a need to streamline various logistics operations, not only at receiving counters, but also at mail-order companies, high-speed railways, and airlines.

In order to solve these problems, we have developed a prototype terminal that "instantly measures the size of luggage and automatically calculates the fare." By easily measuring the size of packages using sensors, we can expect to reduce the operational burden on logistics sites and receiving counters, and reduce the possibility of errors. Find out how this innovation was made possible.

Increase in courier services and challenges in receiving and distributing goods at stores

Since the coronavirus pandemic, the use of online services in daily life has progressed, and this is having a major impact on logistics businesses. In particular, demand for home delivery expanded due to online shopping and person-to-person sales through flea market apps. A survey by the Ministry of Land, Infrastructure, Transport and Tourism found that the number of parcels handled by courier services from January 2020 to May 2022 remained at 100 % to 120 % more than the same month in 2019.

Convenience stores (convenience stores), which serve as the reception desk for many parcels, are faced with issues such as a lack of staff and long working hours by the owners themselves. According to a survey conducted by the Ministry of Economy, Trade and Industry in 2018, 61% of stores answered that they were "short of employees." As the working population decreases in the future, there is a need for ways to reduce the burden as much as possible.

Delivery charges vary depending on the size of the package and the destination. For this reason, when receiving cargo at a convenience store, operations such as measuring the three dimensions (length, width, and depth) of the package using a tape measure and setting the departure and arrival points are required. This receiving process has long been an industry standard, but it often results in lines of customers waiting to check out at the register.

In order to solve this operational problem, we thought that it would be possible to easily measure the three sides of the object using a ToF (Time of Flight) sensor that can measure the distance to an object by measuring the arrival time of light. We have developed a size measurement & automatic price calculation terminal.

What is ToF (Time of Flight) sensor?

A ToF sensor calculates the distance to an object by measuring the time it takes for light to reflect from the object and return. In other words, ToF sensors are very useful for accurately measuring the size and position of objects.

ToF sensors have great potential in instantaneous measurement of baggage size. Using the ToF sensor, you can instantly and accurately measure the size of your luggage. This is much faster than measuring with a tape measure, and there is less measurement error. It also offers very high accuracy and reliability. This allows carriers and other users to calculate rates with confidence, and customers to trust in their accuracy.

The specific principles and mechanisms are described in detail in the following article.

Introducing the principle and reference design of a ToF sensor that can also count people

"Package size measurement & automatic fee calculation terminal" that applies ToF sensors to streamline receiving operations

Manual measurements are not only time-consuming, but also prone to errors. Using traditional tape measure methods, measuring large boxes is extremely time-consuming and can result in measurement errors by the operator. To overcome these problems, metering and billing processes need to be automated. This saves time and effort and provides more accurate and reliable results.

The newly developed ``Luggage Size Measurement & Automatic Price Calculation Terminal PoC'' consists of a ToF sensor, OCR camera, LCD monitor, HDMI and Wi-Fi interfaces, and can solve the above issues.

Prototype device for baggage size measurement and automatic fee calculation terminal

ORAT-0092(OMS)

* Equipped with Infineon IRS2381C chip

*Also uses USB dongle

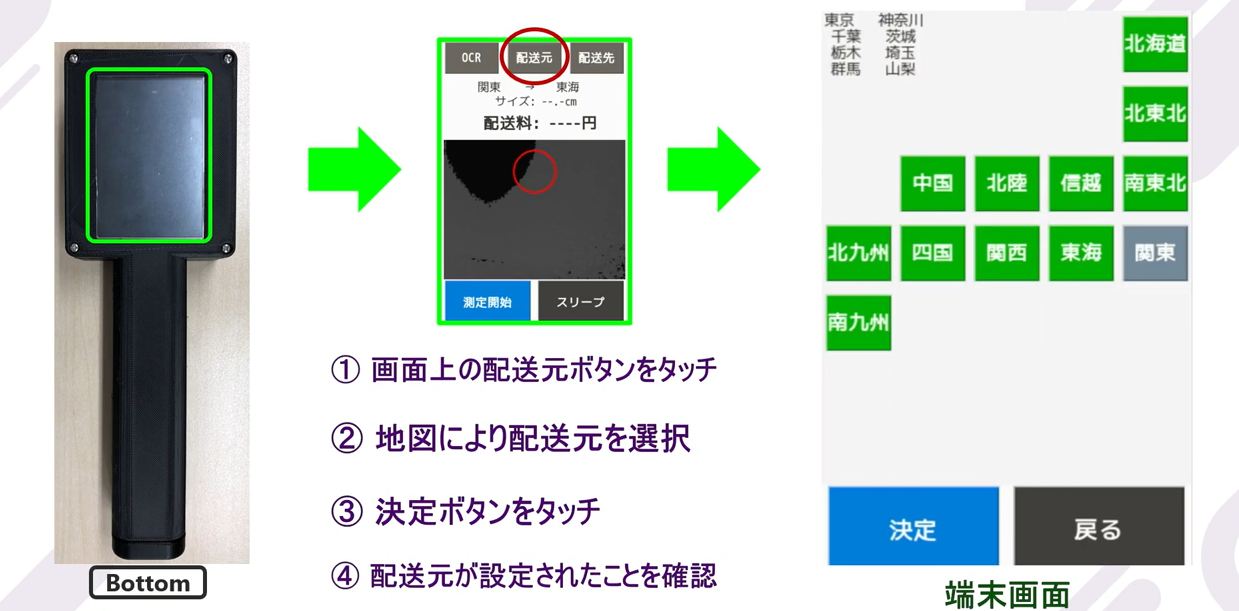

Shipping origin settings

1. Touch the shipping source button on the LCD monitor screen

2. Select delivery source based on map

3. Touch the OK button

4. Confirm that the shipping origin is set

Shipping destination settings

The reason why there is an OCR camera is to read the zip code written on the slip and set the area where the package will arrive. Since the area of the store where the item will be shipped from is fixed, set it in advance on the system.

How to set the shipping address by scanning the postal code

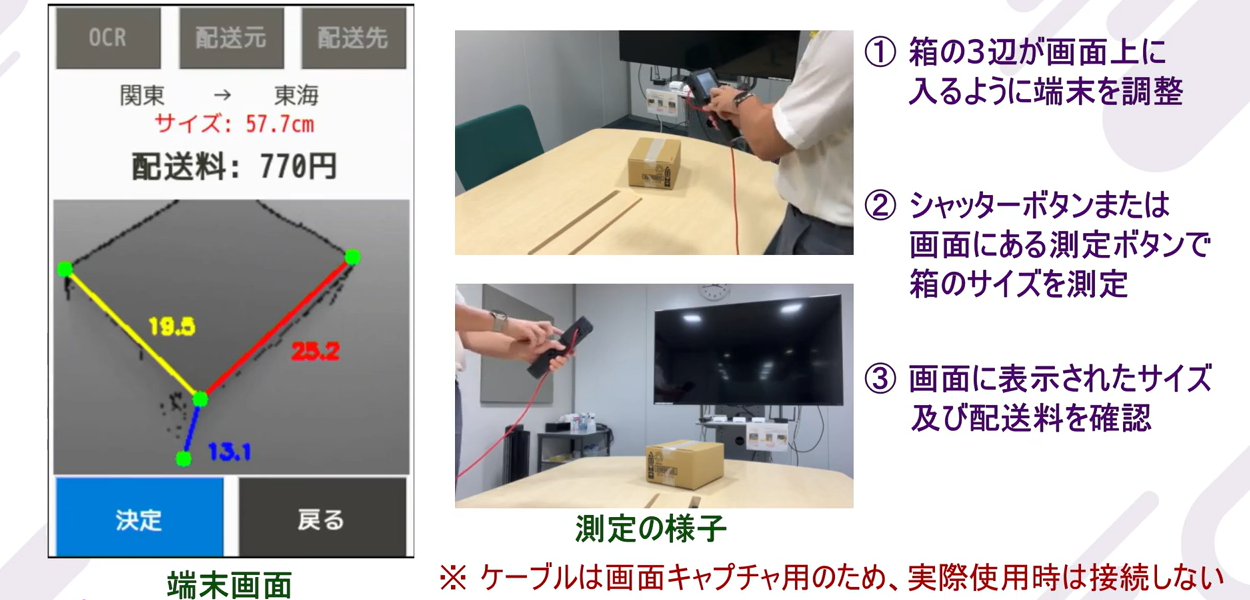

size measurement

1. Adjust the device so that three sides of the box are on the screen

2. Measure the size of the box using the shutter button or the measurement button on the screen

3. Check the size and shipping charges displayed on the screen

When measuring the external size, hold the terminal over the package and press the shutter button, and the ToF sensor will instantly measure it. The receiver can check the measured size on the LCD monitor. Once the departure/arrival location and external size are confirmed, the shipping fee will be automatically calculated and displayed on the screen. The acquired data can be transferred to a PC, etc. via Wi-Fi and linked.

Luggage size measurement

In a PoC conducted at Macnica, receiving a package using this terminal was significantly shortened to 10 seconds, compared to 3 minutes using conventional manual methods. Furthermore, since the terminal used in this PoC uses a general-purpose microcontroller, we believe that a higher-performance device configuration can further reduce reading and size measurement speeds.

Weight measurement is also possible with another system. It can also be applied to online shopping businesses and airline/railway sites.

Depending on the courier service, it may be necessary to measure the weight. In such cases, it is possible to link with "AI Smart Shelf", which was previously developed as a solution to support optimization of store operations.

We believe that these systems can help improve the efficiency of various logistics sites. For example, an "online retailer" that ships a large number of packages every day can use this service to simplify the work of estimating shipping costs. “Airlines” and “high-speed trains” may charge additional fees depending on the passenger's luggage, and may leave it up to the customer to measure the luggage size. Systematization can also be expected to reduce the burden on customers who use transportation services.

Widely applicable to various sites

Macnica utilizes devices such as sensors and technologies such as software and AI to realize solutions to various business issues.

Advances in automation and digitalization offer further possibilities. The convergence of IoT and AI makes parcel tracking and management even more efficient. Advances in data analysis and predictive models will allow us to predict future demand and improve logistics management.

This time, we have developed a device that can be used to measure the external size of parcels in order to reduce the stress on both the store and the customer when receiving packages at convenience stores. This is a solution that is expected to reduce the operational burden on employees at all logistics sites and improve the customer experience.

It can be expected to be used in a variety of other places, including transportation companies, baggage at airports, inspection at factories, and shoe size measurements. At Macnica Monozukuri Consulting, we can apply this technology to build terminals and systems tailored to each customer. If you are interested, please contact us.

Manufacturing consulting service

Manufacturing consulting service Please refer to the button below for details.