EVs (electric vehicles) run by feeding electrical energy stored in a battery to a motor. In order to obtain great power and cruising range, it is equipped with a high-voltage, large-capacity battery pack consisting of multiple cells. A battery management system (BMS) is essential to maximize battery capacity while ensuring safety.

Here, for those considering a BMS, we will introduce the overall configuration of a BMS and the role of each component, along with solutions from Analog Devices, which boasts a top market share in ICs for automotive BMS.

Overall configuration of battery management system (BMS)

Most EV batteries are around 400V, and recently 800V is also available. The battery pack uses 100-200 battery cells with about 4V per cell. These large batteries require precise management of individual cells and entire packs. BMS plays that role.

BMS measures the voltage, current, temperature, etc. of individual cells and the entire pack, and manages the state of charge (SOC) and state of health (SOH). BMS performance is directly linked to range per charge, battery life, cost, size, and safety.

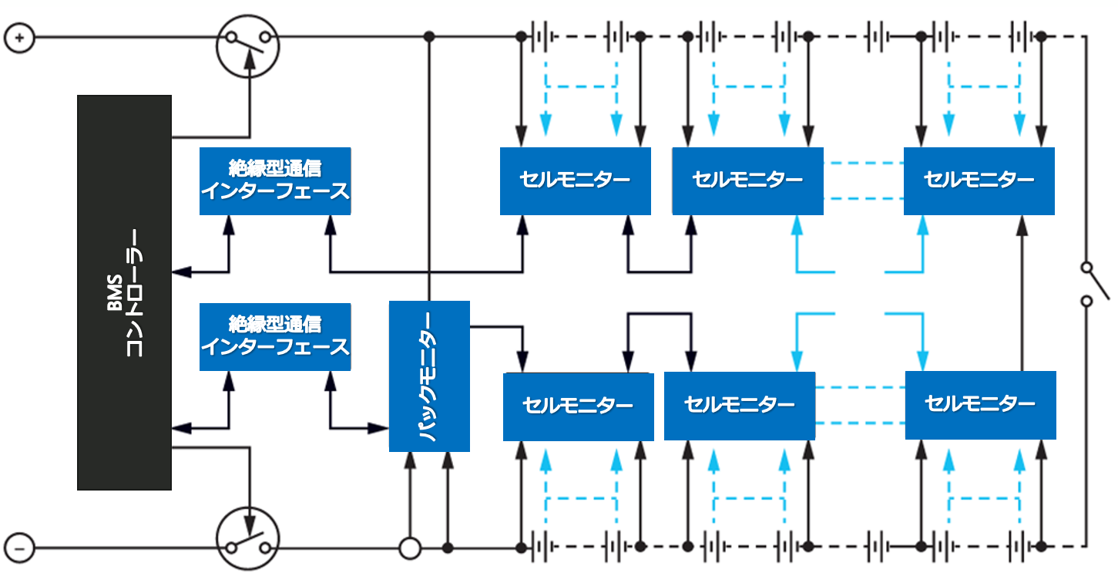

So how is BMS configured? The following three types of ICs are mainly used for the BMS analog front end.

・Cell monitor IC

・Pack monitor IC

・Isolated communication interface IC

Briefly describe each role.

(1) Cell monitor IC

The cell monitor IC monitors the voltage and temperature of each cell and uses a balancing function to equalize voltage variations. The number of cells that can be managed by one cell monitor IC is about 6 to 18, and multiple cell monitor ICs are required to monitor even more cell stacks. Cell monitor IC is sometimes called "BMS IC". It can be said that it is the leading role of BMS.

(2) Pack monitor IC

As its name suggests, it is an IC that monitors the entire pack. Measure key parameters such as current, voltage, energy and charge with high accuracy.

(3) Isolated communication interface IC

It plays the role of efficiently interfacing cell monitor ICs and pack monitor ICs and microcomputers, which are placed in high-potential, noisy environments, with high safety and reliability.

Achieving high-precision BMS using these ICs is the key to extending the cruising range. It is also important to prevent overcharging and overdischarging and to ensure safety.

The role of the cell monitor IC, the main player in the battery management system

From here, let's take a closer look at the functions of cell monitor ICs, which are the mainstay of BMS, while introducing specific solutions from Analog Devices.

The cell monitor IC mainly performs voltage measurement and balancing for each cell. The cell voltage is converted by an AD converter and transmitted to the microcomputer via an isolated communication interface IC. When there is variation in voltage between cells, it can be balanced by discharging.

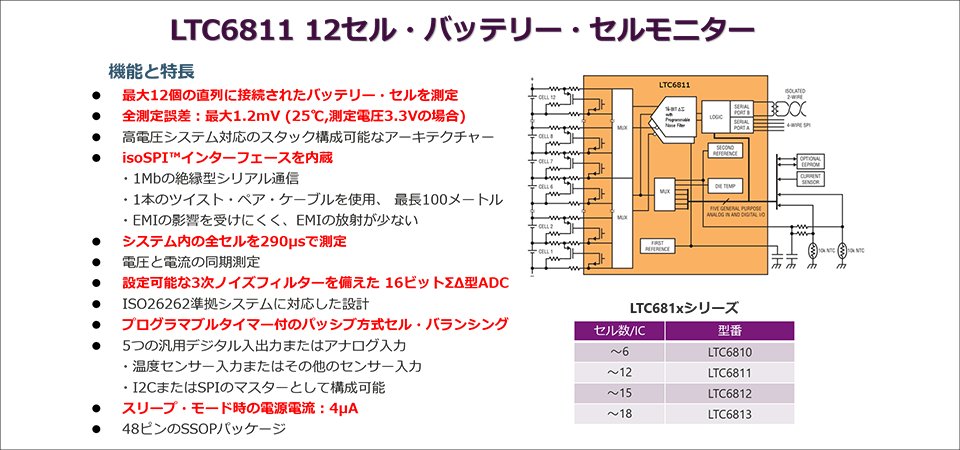

Analog Devices' representative cell monitor IC is the "LTC681x" series, which is attractive for its high precision. Features include:

Features of the LTC681x Series

Features (1) Uses a high-precision embedded Zener reference

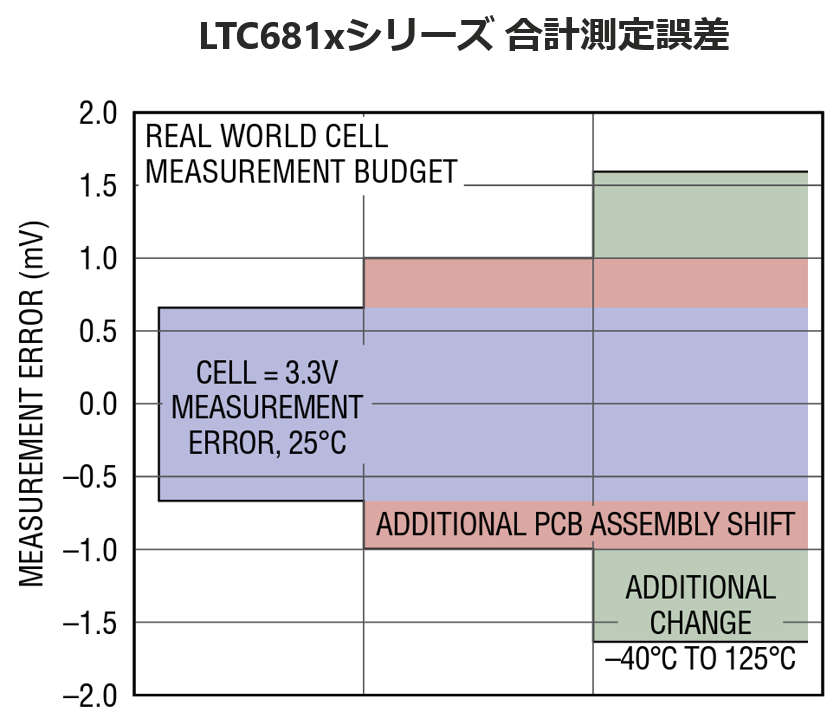

It incorporates a high-quality voltage reference and boasts industry-leading accuracy. Total measurement error can be less than ± 1.2mV at 25 °C ambient operating temperature and less than ± 2.2V from-40 °C to 125 °C (for LTC6811 measurement voltage 3.3V). It does not require factory calibration after PCB assembly, and has excellent long-term stability, temperature characteristics, and hysteresis.

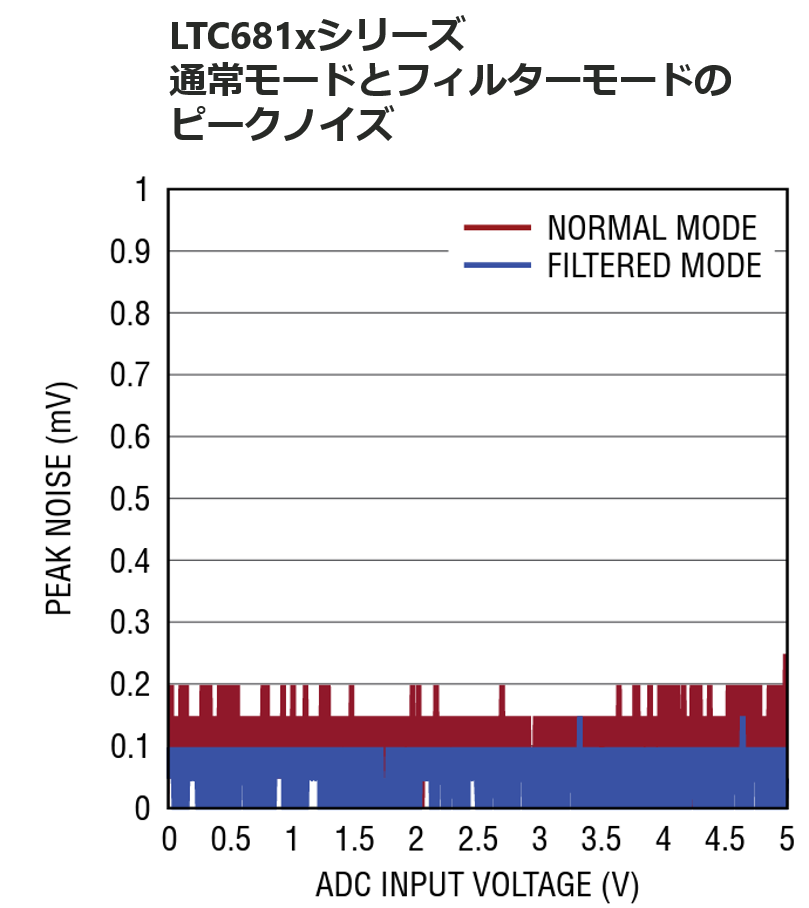

Features (2) Built-in 16-bit AD converter with configurable noise filter

A 16-bit sigma-delta AD converter is used. You can set the filter bandwidth by changing the oversampling rate, and choose the balance between accuracy and conversion speed. Depending on the system requirements, it provides well-balanced normal mode, speed-oriented high-speed mode, noise removal-oriented high-precision filter mode, and additional options for conversion speed.

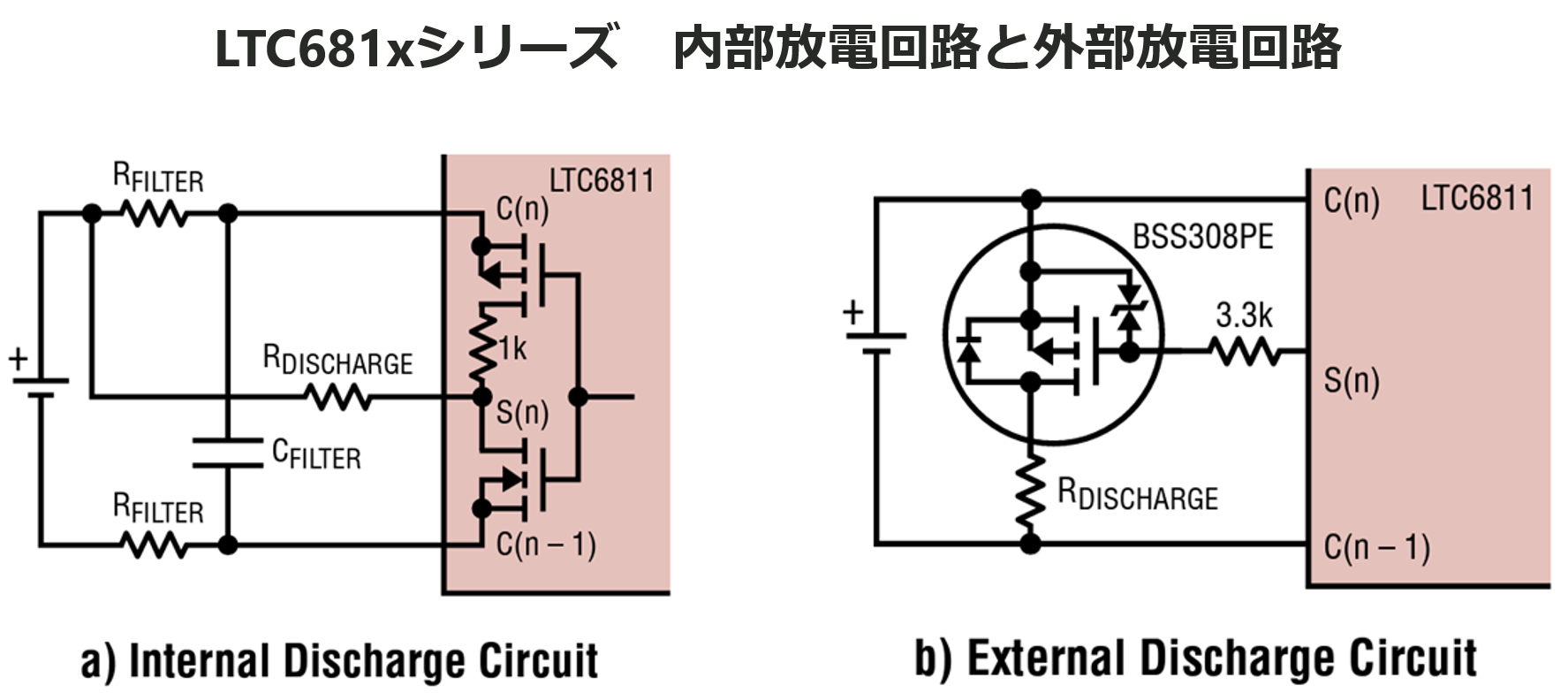

Features (3) Built-in passive cell balancing function

Passive cell balancing allows if one cell in a series stack becomes overcharged, it can be slowly discharged by connecting it to a resistor.

An internal Nch MOSFET with an on-resistance of up to 10 Ω acts as a switch and flows current up to 200mA (LTC6812/3) to balance the cell voltage. If you want to flow more current than that, you can connect an external FET and control it as a current path.

Feature (4) Communication via isoSPI interface

The LTC681x features an isoSPI interface that is noise insensitive and allows for isolated configurations. Multiple devices can be daisy-chained and all controlled by a single host processor. By setting the current and threshold, it is possible to adjust noise immunity according to the system environment and configuration and improve communication reliability. The ability to use a simple 2-wire twisted pair cable also contributes to lower system costs.

The LTC681x series, which incorporates various technologies, enables highly accurate cell monitoring. There is a series lineup for 6 to 18 cells, including the "LTC6811" that can monitor 12 cells.

Why does the accuracy of the cell monitor IC extend the cruising range?

Why is cell monitor IC accuracy important? This is because the effective capacity of the battery changes depending on the accuracy of the cell monitor IC. A battery cannot use all of its capacity. To prevent deterioration due to over-discharging or over-charging, the effective capacity is, for example, a lower limit of 10 % to an upper limit of 90 %. How you can make the most of this range is directly related to battery life.

Cell voltage changes depending on the state of charge (SOC,State of Charge). The measured cell voltage is a parameter for SOC estimation. Therefore, the usable battery area must be designed taking into account the measurement error of the cell monitor IC. For example, in the case of a cell monitor IC that is expected to have an error of ± 5 %, the actual usable area must be considered to be between 15% and 85 %. Running capacity drops from 80% to 70%. An error of ± 1% would result in an 8% increase in running capacity to 78%. This allows you to extend your cruising distance.

Role of pack monitor IC and isolated communication interface IC

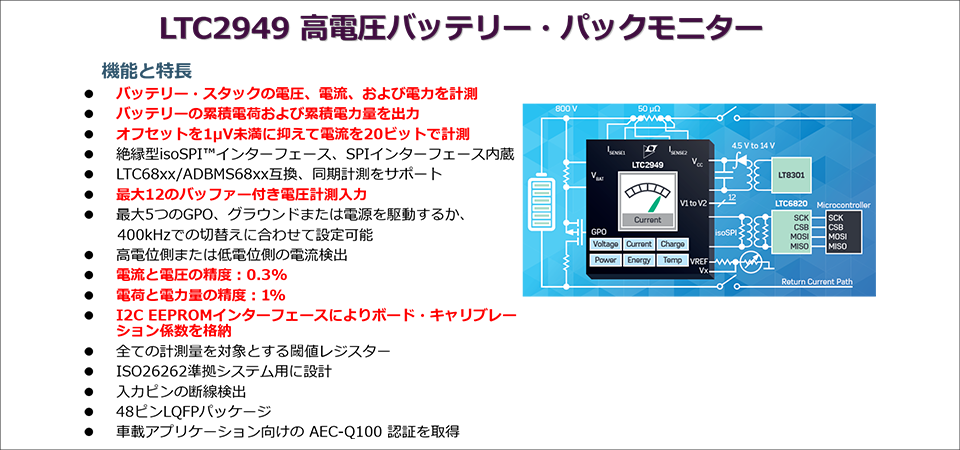

The pack monitor IC plays a complementary role to the cell monitor IC in battery management. Cell voltage can estimate SOC to some extent. However, the cell voltage varies with temperature. Since the temperature fluctuates due to current flow while driving or charging, the cell monitor IC alone cannot estimate the SOC with high accuracy. The pack monitor IC enables more accurate SOC estimation by measuring and accumulating the current flowing into and out of the battery with high accuracy. In addition, it performs multiple monitoring necessary for battery management.

A typical pack monitor IC from Analog Devices is the "LTC2949".

It has a built-in 20-bit high-precision sigma-delta AD converter for current detection, making it possible to obtain measurement results for current, voltage, power, charge, and temperature. It also has a wide variety of functions that cannot be covered by cell monitor ICs, such as a general-purpose AD converter for connecting other sensors, measuring insulation resistance, controlling precharge switches, and monitoring contactor status. It can be connected using the isoSPI interface in the same way as the cell monitor IC.

Isolated communication interface that can be used as a set with cell monitor IC and pack monitor IC

The role of the isolated communication interface is to electrically separate the high-voltage battery and control system, improve safety, and improve signal noise immunity.

The "LTC6810/20" is an isolated communication interface IC that can be used as a set with Analog Devices' cell monitor IC and pack monitor IC. It converts the 4-wire SPI signal that microcomputers generally have into a noise-resistant differential isoSPI interface and transmits it insulated via a transformer.

You can read more about isoSPI technology in this article. Please take a look at it.

In addition, Analog Devices offers a rich product portfolio for BMS. ASIL-D compliant products with enhanced self-diagnostic functions have also been released. If you are interested, please feel free to contact us.

Application example

·Electric car

・Hybrid car

Click here for recommended articles/materials

Click here to purchase products

Click here for manufacturer site/other related sites

Inquiry

If you have any questions regarding this article, please contact us below.

Analog Devices Manufacturer Information Top

If you want to return to Analog Devices Manufacturer Information Top, please click the button below.