Introduction. “Is there a way to streamline the inventory work without relying on people or experience?”

Have you ever wondered, "Isn't there a way to make the store's stocking process more efficient?"

What kind of products are sold in the large store? Are you running out of stock? It's difficult to always keep track of things like this with only a limited number of staff. Some stores have intercoms to share information and cooperate with each other, but even so, it is not possible to grasp 100%.

But what if we could “use electronics technology” here? Until now, all judgments were made by people, so it seems that there was a big difference in experience, but if you use electronics technology, even newcomers can work efficiently.

In recent years, image recognition technology and sensing technology have evolved to a level that cannot be overlooked. the Company would like to invite you to take a look at our presentations, including actual examples that utilize our strengths in electronics technology.

The problem of "stocking out products" in supermarkets

A bargain that attracts customers at supermarkets. What would happen if you went to a store looking for a bargain item and the bargain display shelf was empty? If I were you, I'd be right back.

Even if it's not a bargain item, there may be some items that suddenly became popular because they were featured on TV programs or introduced by celebrities on social media. In such a case, we definitely want to avoid a situation in which we lose sales opportunities because we have inventory in the warehouse, but we have not been able to put it out. As with sales, it will be a disappointing result for both parties that betray the customer's expectations.

So why do stocks run out?

1. Unable to grasp sales (selling speed)

As with anything, if you don't try, you won't know the results. A product you thought would sell might not sell as well, and vice versa. It seems to depend on the time of day and the weather.

I don't understand these predictions without experience. A team made up of only veteran employees can take actions based on predictions, but in cases where only inexperienced part-time staff have to turn the work around, predictions cannot be made and there is a situation where products are out of stock. I wake up.

2. Worker dissatisfaction

When I asked someone who had experience selling items, they said that it was not a very enjoyable task. At first, it takes a long time because they can't remember where the product shelves are, and they seem to be dissatisfied that once they learn a job, they get bored with simple work. In addition, it seems that there are many complaints unique to humans, such as getting a backache when lifting a heavy box of potatoes, cutting a hand with a cardboard box, and being cold in the air conditioner. (I will explain how to solve this dissatisfaction on another occasion.)

Maximize product availability and sales opportunities!

What can be done to resolve these issues and complaints?

This is probably the use of "AI, electronics technology". As I mentioned at the beginning, the level of image recognition and sensing technology in recent years is extremely high and can be introduced at low cost. Solutions that were shunned until a decade ago because they were not cost-effective are now available at low cost and with immediate results.

Therefore, why not install a "sensor" to monitor the display status of products or try "automatic recognition with a camera"?

By sending out alerts (notifications) via smartphones, computers, in-store announcements, warning lights, etc., based on the monitoring results, such as "How many products are left on the shelves?" or "Are customers returning products to the wrong places?", Know when is the right time to stock items.

No need to constantly walk around the store! "A system that allows you to respond only as much as you need, when you need it.” All you have to do is make it.

At Macnica, these Helping you create a system to solve problems from scratch It is also possible to Support for product development only We also do

Flexible response according to customer issues and requests I will do it.

What "manufacturing consulting" can support

1. Proposal of various sensors

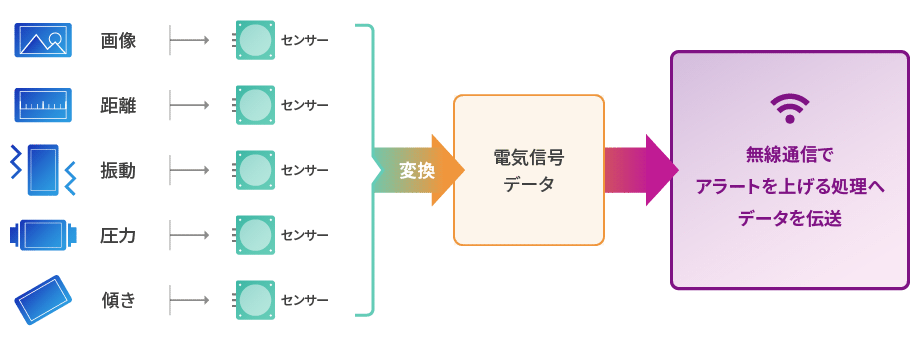

A sensor is a device or apparatus that converts physical or chemical phenomena into electrical signals or data and outputs them.

To put it simply, they play a role in handling the five human senses, such as sight and hearing, in the same way in electronic devices.

However, while humans are able to make complex judgments by combining sight and hearing, electronic devices cannot make such judgments, so we must select the most suitable sensor for the purpose of use.

In the case of stocking this time, we will install appropriate sensors on the product shelves in order to know in real time the information "how many products have decreased".

After that, we can replace the human eye only by telling the employees the information "how many products have been reduced" obtained by the sensor. Next, let's consider how to convey it.

Transmission method of information acquired by the sensor

2. Examination and construction of alert method

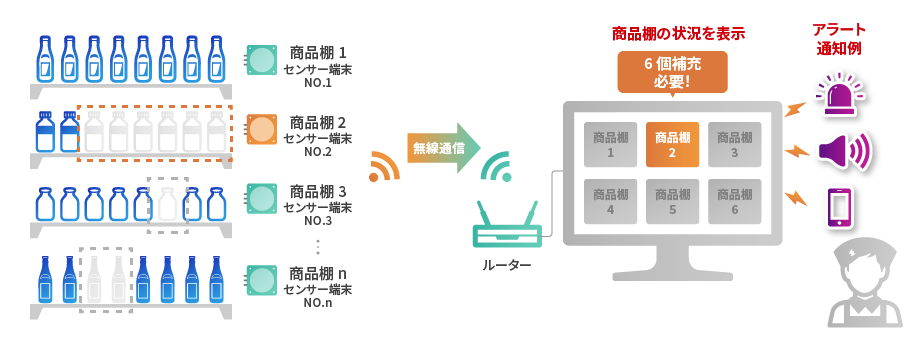

In order to receive the sensor information of "how many items have decreased" and actually put them out, it is necessary to send an alert (notification) to the employee that "how many items have decreased". To do this, we first prepare a sensor terminal to be attached to each product shelf, and a router and PC to which the information will be sent.

Communication from the sensor terminal to the router is performed wirelessly. There are many types of wireless, and Bluetooth and Wi-Fi are commonly used, so it is easy to imagine. must be considered.

So, let's take the 920MHz band as a candidate. The 2.4GHz band (wireless LAN, Bluetooth, etc.), which is often used as a wireless band, is sometimes said by facility managers, ``I don't want you to increase the 2.4GHz band any more because it causes crosstalk.'' The 2.4GHz band is inferior to the 920MHz band in terms of radio wave reachability, so the 920MHz band is recommended for applications where lower throughput (*) is acceptable.

When the router receives the sensor information, set it to display the low inventory status of each shelf on the PC screen. Example) "Product shelf 2 (decrease in 〇 pieces)"

Based on that information, how about doing the following, for example?

[Example of alert notification]

・Turn on the product shelf lamp

・Send an internal announcement that only employees can understand

・Let employees hold smartphones and send notifications

Identifies "How many products on which shelf have decreased?"

Which "sensor" and which "wireless method" are best to use? We will make proposals according to the purpose and situation that the customer wants to achieve.

[*Note]

Throughput is the processing power per unit time. You don't have to keep sending out-of-stock alert signals every tenth of a second.

Low-power radio below 1 GHz is commonly called Sub-GHz.

<Features of 920MHz band>

・Communication distance is theoretical value 25km, practical value 100~200m (about 10 times of 2.4GHz band)

・Transmission speed is 100kbps (more than 10 times faster than 400MHz band)

・Less influence of interference (WLAN / Bluetooth / microwave oven, etc.)

3. How to use data

It is also easy to store the data acquired by the sensor in the cloud.

In the future, it is also possible to use the acquired data for sales promotion, and to process such data in the cloud and provide notifications (advice).

You can visualize information that was vague until now, such as products that sell when the temperature is high, and products that sell on rainy days.

4.Others

If you have any problems or requests other than the above, please feel free to contact us. We will respond flexibly.

Summary

The contents introduced this time are not limited to supermarkets, convenience stores, home centers, etc., but can be used in various situations such as bookstores, pharmacies, hospitals, warehouses, etc. It can also be used with the keyword "inventory management", such as checking the remaining amount of tableware at restaurants.

We were unable to introduce a solution to dissatisfaction of workers at this time, but robots that automate product delivery will be active in the future. Demand forecasting (ordering), pricing, staffing, etc. should also determine the optimal solution.

In addition, there is no doubt that the introduction of AI will contribute to increasing sales, but the important thing is to know the answers to the questions "Why are you not selling?" and "Why are you selling so much?" If we don't find out the cause, it's only natural that we'll run out of stock and lose opportunities.

First of all, why don't you start by quantifying and understanding the parts that rely on experience and intuition?

About "manufacturing consulting" service

For details on Macnica "Manufacturing Consulting" service, click here

Inquiry

If you would like to introduce a service like the one introduced in this article, or if you would like to consider it first, please feel free to contact us below.