AC-DCフライバック電源を設計する際に、制御ICの選択はその後の工数を大きく左右します。

適切な制御ICを選ぶことで電源設計の工数を大きく削減し、将来の拡張性にも対応することができます。

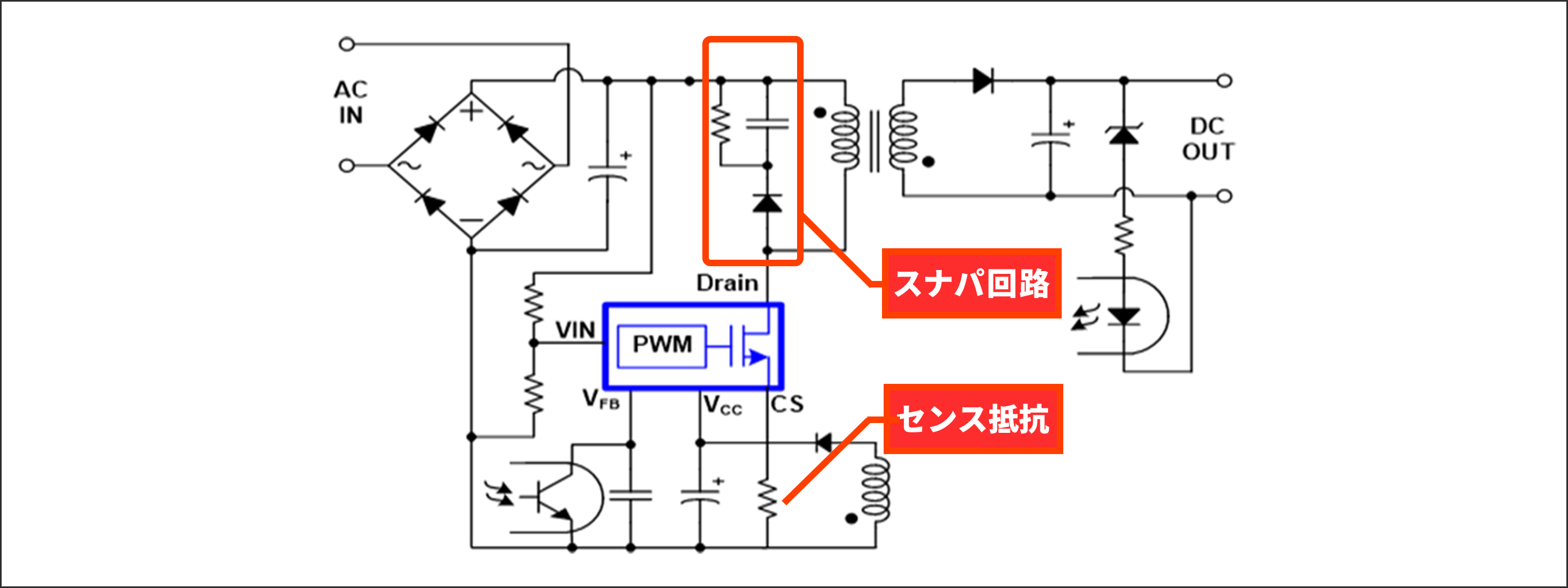

本稿では、AC-DCフライバック電源用の制御ICの中で、高耐圧スイッチング用FETを内蔵した制御ICについて紹介します。

FET内蔵のスイッチング電源制御用IC(以降Switcherと表現します。)は、FET外付けタイプの制御ICにくらべ、以下の3つのメリットがあります。

・ 実装スペースが小さい

・ 低コストである

・ 電源設計が簡単

一方で、FETが固定であるために、評価中に少し効率が足りない、発熱が大きい、ノイズが規格内に収まらないという課題が出た場合に、対処法が限定されるといったデメリットもあります。

最適な制御ICを選択することが、このようなデメリットを最小化することにつながります。

本稿では、以下について紹介します。

1.どのような電源でSwitcherを使うべきか

Switcherは電源の小型化に最適です。

DIP-8やSO-8のパッケージの場合、現在販売されているSwitcherでは、30Wから40Wくらいまでが可能な出力範囲と考えます。したがって、これ以下の出力で、小型、低コストが重要であるならばSwitcherはベストな選択です。

一方で、それ以上の出力が必要な場合は、より大型のパッケージのSwitcherを選ぶか、もしくは、FET外付けの制御ICを選択することをお勧めします。

2.出力とFETサイズの選び方

Switcherのデータシートを見ると、下図のような最大出力を記載した表が掲載されています。

Switcherに内蔵されたFETの能力とパッケージの熱抵抗によって電源の出力はある程度決まります。実際には、電源の放熱設計に依存するので、この表のデータはあくまで参考値になります。

Open Frameとは、ケースなどもなく、周囲への放熱がよい状態の電源を意味し、Adapterとは電源がケースで覆われ、周囲への放熱が制限されたものを意味しています。

したがって、Adapterのほうの出力がOpen Frameよりも小さくなっています。

また、入力電圧範囲が85~265VACのほうが、230VACよりも出力が小さくなります。

まずはこの表に記載の出力電力を最大出力と考えて製品を選ぶことができます。

| Part Number | PKG |

Switching Frequency |

Max. RDS(ON) [Ω] |

Output Power Table [W] | ||

| Adapter | Open Frame | |||||

| 85 ~ 265 VAC | 85 ~ 265 VAC | 230 VAC | ||||

| NCP11184A065PG | PDIP-7 | 65 kHz | 2.25 | 18 | 25 | 37 |

| NCP11185A065PG | 1.3 | 22 | 30 | 45 | ||

| NCP11187A065PG | 0.65 | 30 | 40 | 60 | ||

| NCP11184A100PG | 100 kHz | 2.25 | 18 | 25 | 37 | |

| NCP11187A100PG | 0.65 | 30 | 40 | 60 | ||

3.モノリシックタイプと2チップタイプ

Switcherには大きく分けて2種類の製品群があります。

・モノリシックタイプ

・2チップタイプ

|

|

モノリシックタイプ |

2チップタイプ |

|

チップ構成 |

FETと制御回路が同一チップ上 |

FETと制御回路が別チップ |

|

FET構造 |

横型 |

縦型 |

|

コストパフォーマンス |

低出力で有利 |

高出力ほど有利 |

|

アバランシェ耐量 |

× |

○ |

モノリシックタイプは、一つのシリコンチップ上に高耐圧スイッチング用FETと制御回路を形成します。

2チップタイプは、制御回路のチップと、ディスクリートの高耐圧スイッチング用FETと2つのチップをワンパッケージにしています。

モノリシックタイプで用いられるFETはドレインとソースがチップの表側に配置された横型構造となります。

2チップタイプで用いられるディスクリートのFETは、通常、ドレインが裏側でソースが表側に配置された縦型構造です。耐圧が高くなるほど、オン抵抗が低くなるほど、縦型構造の方がより低コストで小型にするのに有利になります。

したがって、同じチップサイズであれば、上記の構造上の理由により、モノリシックタイプのFETは、ディスクリートのFETよりも高抵抗になってしまうために、高出力になるほど2チップタイプのほうが有利になります。

以前は、組立コストが高かったために、モノリシックタイプの製品が主流で、低価格でラインアップも多かったのですが、近年の組み立て技術の急速な向上により、2チップタイプのものも安価になってきました。

また、パッケージを限定した場合、パッケージに搭載できるチップサイズには限界があるので、より低抵抗のMOSFETを搭載できる2チップタイプの方が、より高出力を実現できます。

さらに、2チップタイプのメリットの1つとして、堅牢性が挙げられます。

モノリシックの場合は、高耐圧スイッチング用FETと制御回路とが同一チップ上に形成されているために、雷サージなどがFETの端子に印加されたときに、FETと制御回路間でラッチアップが発生して破壊することがあります。

2チップタイプの場合、FETと制御回路が物理的に分離されているため、このようなラッチアップが発生することがなく、雷サージに対して高い耐性を示します。

またモノリシックタイプのFETでは、一般的にアバランシェ耐量が低く、スペックシートにも記載がないのに比べ、2チップタイプのFETではスペックシートにアバランシェ耐量が記載されています。

このように2チップタイプの電源制御用ICは、高出力、高効率、堅牢性というメリットを備えています。

一方で、数W程度の低出力のスイッチング電源になると、必要とされるFETのサイズが小さくなるので、モノリシックタイプのSwitcherの方がコストパフォーマンスはいいかもしれません。

4. シリーズラインアップが重要

Switcherを選択するさいには、FETサイズ、ドレイン電流リミット、周波数のラインアップがそろえられていることをチェックすることが重要です。

電源評価をしてみたら少し効率が足りない、少し発熱が大きいといった問題は頻繁に発生します。

トランスを変更して対応できればいいのですが、その効果が得られない場合や、トランスが変更できない場合、FETがワンランク上の製品や、周波数やドレイン電流リミットが異なる製品を同一シリーズから選択できなければ、PCBの設計のやり直しや、大幅な回路の見直しが必要になってしまいます。

したがって、FETサイズなどのシリーズラインアップが充実している製品を選択することが必要です。

5. スイッチング周波数は効率とノイズに影響する

多くのSwitcherが周波数固定の電流モードPWM制御方式を採用しています。

(最近では、Frequency Foldbackなど、軽負荷時には周波数を低減させて効率を改善する制御方式が一般的になってきていますが、本稿では、これらも含めて周波数固定の電流モードPWM制御方式と呼称します。)

基本周波数は、メーカーによって多少の違いはありますが、60kHz, 100kHz, 130kHzの3タイプが多くみられます。

周波数は、効率とノイズに密接にかかわります。効率、ノイズを優先させると、低周波数の方が有利になります。

一方で、高周波数の方がより小型のトランスコアを選択できるというメリットがあります。

この周波数によってトランスの設計も異なるので、最初に周波数を選択する必要があります。

6. ドレイン電流の過電流保護リミットは最も重要

電源設計において、スイッチング周波数と並んで重要なパラメーターがドレイン電流の過電流保護リミット(ILIMIT)です。

多くのSwitcherでは、このILIMITが内部固定となっており、微小な調整ができません。

このようなSwitcherでは、冒頭で話したように、評価の結果、少しパワーが足りないという問題が発生すると、ワンランク上のICに置き換えることになり、システムのコストアップになります。

ILIMITを設定するセンス抵抗が外付けなっており、電源設計者が外部調整できるような製品であれば、FETが許容できる範囲でILIMITを調整することができるので、このような問題を簡単に解決できます。

さらに、ILIMITはドレイン電圧にも影響を与えます。

ILIMITが大きすぎる場合は、トランスコアが飽和し、ドレイン電圧が耐圧に対してマージンが不足することがあります。

このような場合も、ILIMITを外部調整できることは、電源設計者にとっては非常に便利です。

また、この外付けセンス抵抗のメリットは、自由にドレイン電流リミットを選択できるという設計自由度のほかに、ディスクリートの抵抗素子を用いるので、ドレイン電流リミットの精度が高いというメリットがあります。

制御ICに内蔵されたセンス抵抗は、半導体素子で形成されているので、ディスクリートの抵抗素子よりも温度特性、ばらつきが大きくなります。

7. FETのドレイン耐圧は効率にも影響

AC-DCフライバック電源で使用される一次側スイッチング用FETは、通常600V以上の耐圧が必要です。

特に、起動時や負荷変動時、制御モードの切り替わり時などにドレイン電圧が最も大きくなります。

電源設計のさいには、あらゆる条件において、FETのドレイン電圧が絶対最大定格に対して十分なマージンをもつように設計しなければなりません。

通常は、対策として、スナバ回路を使って、リーケージインダクタンスによって生じるサージノイズを吸収させます。

スナバ回路の抵抗値を小さくするとサージノイズが小さくなりますが、スナバ回路でのロスが大きくなるため電源の効率が低下します。

したがって、FETのドレイン耐圧が高いということは、安全性の確保とともに、スナバ回路を軽くすることができ、効率を改善することにもつながります。

8. ノイズ対策は面倒で難しい

雑音端子ノイズ試験は、一通りの電源評価が実施され、電源の基本動作が確認された後の工程で行われるものですが、回路だけでなく、パターン設計、トランス構造など多くの要因が絡むので、対策には経験と時間が必要となります。

ノイズ対策のフィルターを追加すると、再度効率、温度の評価もやり直すことになります。

あらかじめノイズ対策の機能を持った製品を選ぶことで、電源設計の最後の工数を削減できます。

フライバック電源で一般的なノイズ対策としては、疑似共振制御(QR)と周波数ジッター機能があります。

他にもActive Clampという技術もありますが、部品点数が増えて高価になることと、SwitcherでActive Clampに対応した製品が無いために本稿では触れません。

疑似共振制御は、ノイズ、効率に対して有効な制御方式ですが、常に非連続モード(DCM)での動作となり、重負荷になるほど周波数が低くなるので、一次側に大きな電流を流す必要があります。

連続モード(CCM)での動作も可能な周波数固定のPWM制御方式に比べると、より低抵抗のFETが必要となり、トランスのコアサイズも大きくなります。

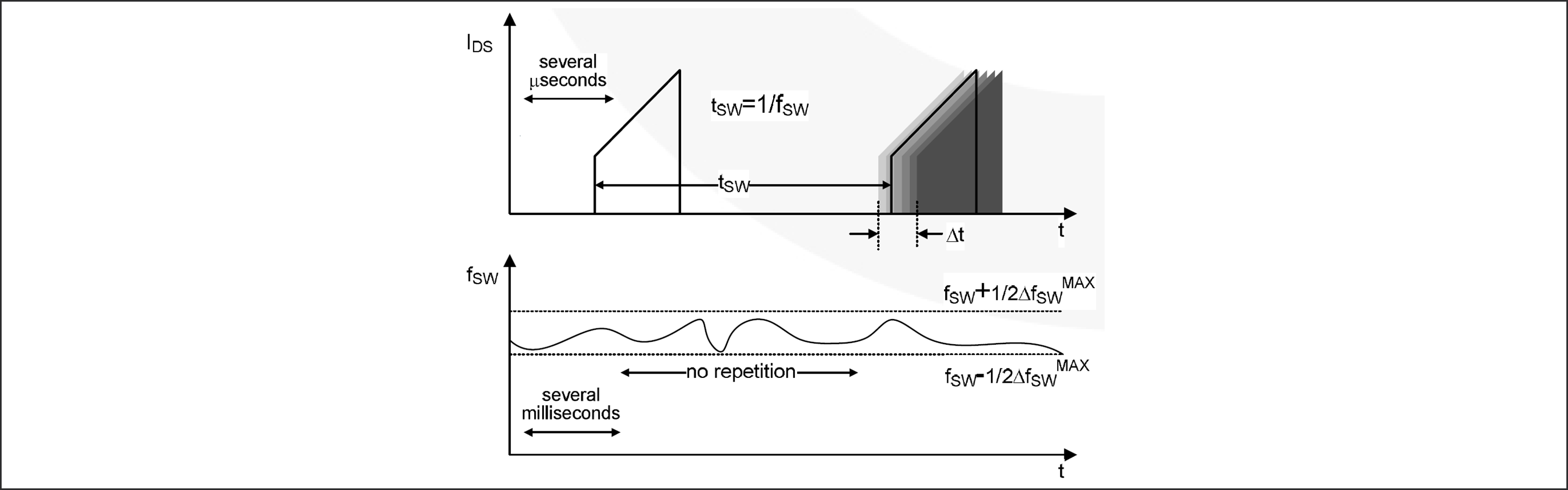

周波数ジッターは、Frequency hoppingやFrequency Modulationなど各社さまざまな方式、呼び方がありますが、スイッチング周波数に意図的に揺れを与えることで、スペクトラム拡散させるという意味では同じ技術です。

簡単な技術ですが、EMIアベレージノイズを低減させる効果があり、ノイズ対策の工程を削減させることができます。

また、この技術は、疑似共振ほどの効果はありませんが、大きなデメリットはありません。

9. スロープ補償がないとトランス設計が難しい

スロープ補償は、サブハーモニック発振を防ぐために効果的な機能です。

ローコストタイプの制御ICには、このスロープ補償が備えられていないものがあります。

スロープ補償がない場合、連続モード(CCM)動作においてもDutyが50%以下になるようにトランス設計をする必要があります。

CCM動作かつ、Dutyが大きくなるのは、低入力電圧で重負荷の条件です。

もしスロープ補償がなく、CCM動作かつDutyが50%以上で動作すると、サブハーモニック発振による不安定な動作となり、音鳴りが発生したり、過負荷保護が設定値よりも低い負荷で動作したりする恐れがあります。

スロープ補償により、電源の設計許容範囲が広がります。

オンセミは、FET外付けの電源制御ICとともにこのSwitcherでも多くのラインアップを持ち、精力的に新技術開発をおこなっています。

オンセミのWebサイト上では、FET外付けタイプをオフライン・コントローラー、FET内蔵タイプをオフライン・レギュレーターと表記しています。

電源制御ICやSwitcherにご興味をいただいた場合、下記問い合わせボタンにてお問い合わせいただければと思います。

お問い合わせ

オンセミメーカー情報Topへ

オンセミ メーカー情報Topに戻りたい方は以下をクリックしてください。