What was the "past" like?

Electric cars have seemed like the realization of decades of future ambitions, but in 1900 they actually outnumbered gasoline cars by nearly two to one. Today, advances in motors, batteries, chargers, and the electronics that connect them together are making EVs once again a serious contender in the automotive market. Power semiconductor switches are very important in this application, and new advances in wide bandgap silicon carbide devices are enabling even higher performance.

All for efficiency

Dr. Brown from Back to the Future would have understood that energy efficiency and consequent range of EVs has been a weakness since their first appearance as road transport in the mid-19th century. Still, advances in battery and motor technology allowed EVs to outperform internal combustion engines by almost two to one in America in 1900. Electric vehicles, which accounted for 38% of the road vehicle market, were overtaken by steam engines at 40%. dominated the 20th century.

Today, the usefulness of EVs is unquestioned. It is very eco-friendly, and the running cost is only a fraction of that of a gasoline-powered car, and the performance of a supercar can be demonstrated. However, initial cost, charging time, and annoying “range anxiety” are barriers. While economies of scale are driving down purchasing costs over time, improving battery charge times and distances traveled on a charge remains a focus of efforts by power electronics engineers.

Chargers are divided into in-vehicle type and home/roadside type. The inefficiency of the OBC (on-board charger) is directly related to the length of charging time, and the wasted power must be dissipated by a large and heavy cooling device, which affects the cruising range. Roadside or fast home chargers allow much quicker recharging, but electrical inefficiencies here lead to higher energy bills and larger, more expensive products, so they are widely available. It is not economical to do so. Improving efficiency is therefore the key to progress.

Realization of high efficiency with wide bandgap semiconductors

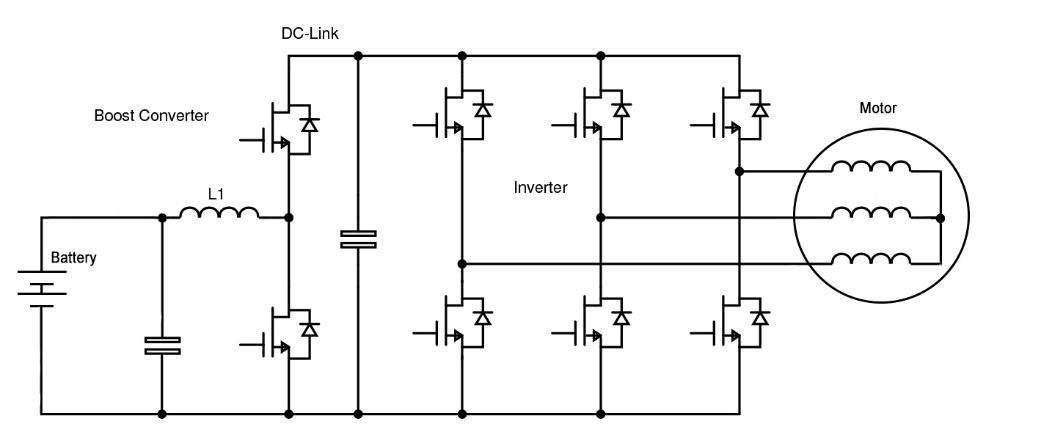

Until recently, the semiconductor switches found in EVs were IGBTs, dating back to the 1960s. Of course, devices are improving year by year, but there is a problem that loss increases when switching at high frequencies. For this reason, the EV motor drive operates around 10kHz, which is difficult to filter. As a result, ripples are generated in the output of the inverter drive, which causes a decrease in efficiency due to motor wear and iron loss. EV drives also need to operate bi-directionally to charge the battery when coasting or braking, and IGBTs that do not conduct in reverse require parallel diodes.

Replacing IGBTs with wide bandgap semiconductors, specifically silicon carbide FETs, can be much more efficient than IGBTs and at much higher frequencies. Motors run more efficiently because they are easier to filter, and faster switching allows for better control of the motor, eliminating effects such as audible noise and torque ripple that cause motor wear. Masu. SiC FETs also have a low-loss diode effect that allows reverse current, eliminating the need for a separate parallel diode. As a package, a bi-directional EV boost converter and inverter can be more efficient overall, smaller and lighter, all of which help improve range. A key advantage is that SiC FETs are available in packages that can be dropped-in as replacements for many existing IGBTs, resulting in instant performance improvements. Devices are currently available from Qorvo with on-resistances below 10mΩ for 1200V class devices and below 7mΩ for 650V types suitable for 800V and 400V battery systems respectively.

Car chargers may already use high-frequency switching Si-MOSFETs, but they have gone from front-end “totem-pole” PFC stages to main bridge converter switches and even output rectifiers that can synchronously drive SiC FETs. By using SiC FETs in all stages, you can benefit from efficiency gains. Home chargers can become smaller, more efficient and save energy using SiC FETs. In fast loadside chargers, SiC FETs can be used for the "Wien Rectifier" three-phase front-end, which can be easily paralleled in the main conversion stage and can handle outputs up to hundreds of kW. . Increased efficiency translates into energy savings and less cooling hardware, lowering costs and encouraging the deployment of more charging stations, resulting in greater economies of scale.

Electric vehicles are set to become the transportation of the future, with wide bandgap semiconductors such as SiC FETS being chosen as power semiconductor switches. Dr. Brown and Marty wouldn't have to go too far into the future to see the past repeat itself. EVs also beat gasoline vehicles in charging time and range.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.