The demand for digital isolators has increased in recent years. Even if you have a vague understanding of the existence of the magnetic isolation method and the capacitance method, many of you may be wondering, "I don't really understand the differences and features," or "Which one is more suitable for my application?" Is it not?

This time, after explaining the differences and features of the magnetic isolation method and the capacitance method of digital isolators, the first part will introduce the Analog Devices lineup of magnetic isolation methods.

Digital isolator attracting attention as an insulation method to replace photocoupler

In circuit design, isolation is performed to improve safety and quality. Safety can be ensured in devices that are directly touched by humans and in circuits with large currents by preventing static electricity, electric leakage, short circuits, and device failures through insulation. It also improves signal transmission quality by isolating noise from ground loops and the like.

Photocouplers have long been the only option for isolation technology in the industrial, automotive, and medical fields. On the other hand, photocouplers have the following drawbacks.

<Disadvantages of photocouplers>

・Uses light for insulation, so consumes a lot of power

・The data rate is usually about 1 to 10 Mbps, and there is a limit to the transmission speed.

・In order to maintain performance while compensating for deterioration of the light-emitting part, power consumption increases with age.

Therefore, in recent years, digital isolators have been attracting attention as a technology that can replace photocouplers. Digital isolators have the following advantages and can overcome the shortcomings of optocouplers.

<Advantages of digital isolator>

・High-speed data rates such as 150Mbps are possible with little propagation delay

・Low power consumption and no increase due to aging

・Excellent temperature characteristics, withstand voltage, CMTI, surge resistance, etc., and high reliability

Due to these characteristics, digital isolators are increasingly being chosen for applications that require higher performance, reliability, and robustness.

Types of digital isolators

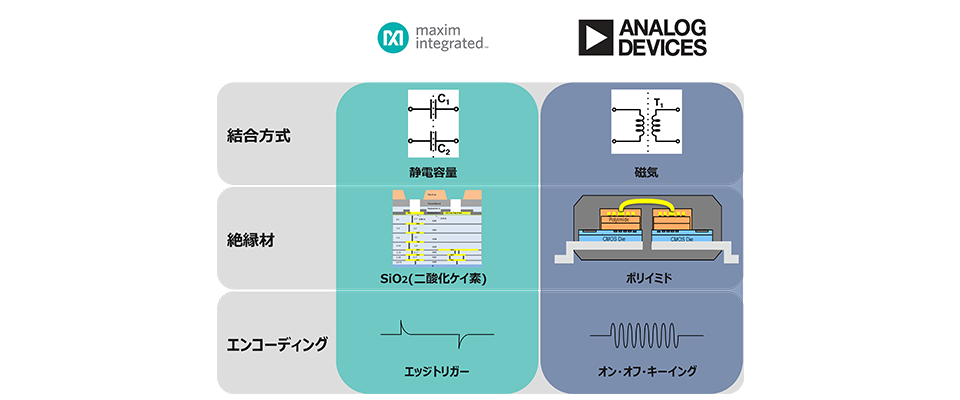

There are two types of digital isolators: capacitive type and magnetic isolation type. Analog Devices has both lineups.

The line-up of the former Maxim, which was merged with Analog Devices, mainly adopts the capacitive method. SiO2 (silicon dioxide) is used as an insulator, and encoding is triggered by an edge.

The traditional Analog Devices lineup mainly uses the magnetic isolation method. Polyimide is used as an insulating material. On-off keying is the mainstream of encoding.

Learn more about on-off keying

The figure below shows the image of the old Maxim on the left and the lineup of Analog Devices on the right.

Which one should you choose? ~Magnetic Insulation vs Capacitance~

So which one is the wiser choice? Let's think while introducing the features of both.

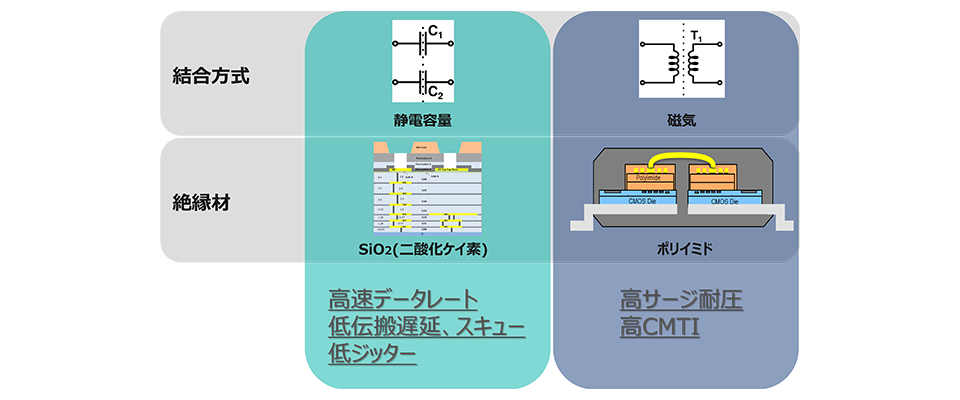

Differences due to bonding method and insulating material

The capacitive method of the former Maxim's lineup uses SiO2 as an insulating material, and features high transmission speed, low propagation delay, low skew, and low jitter. On the other hand, the conventional magnetic isolation method in the Analog Devices lineup uses polyimide as the insulating material, and features high surge withstand voltage and high CMTI.

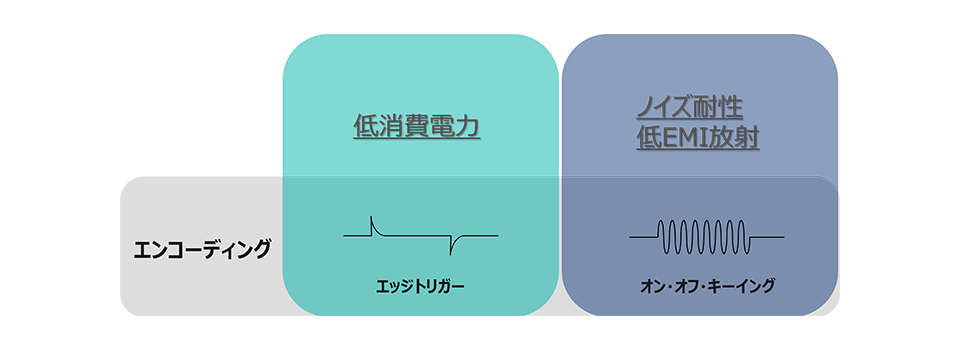

Encoding differences

The former Maxim line-up (capacitance method) uses an edge-triggered encoding method to achieve low power consumption. On the other hand, the on-off keying method, which is the mainstream in the old Analog Devices lineup (magnetic isolation method), contributes to improved noise immunity and reduced radiated EMI.

Which one is best? Each application example

As you can see, both have different features. It is important to consider the strengths of each and choose the method that best suits your application. Below are brief examples of suitable applications for each.

<Examples where the capacitance method is suitable>

For applications where high speed and low power consumption are important, we recommend the old Maxim line-up, which mainly uses the capacitive method. Many products are competitively priced and can be used for general purposes.

(example)

·handy terminal

・Portable measuring instruments

・Various consumer products

<Examples where the magnetic insulation method is suitable>

For applications that require ruggedness and reliability, we recommend the legacy Analog Devices line-up, which focuses on magnetic isolation. You can expect stable operation even in noisy environments.

(example)

・Medical applications (endoscopes, blood test equipment, etc.)

・In-vehicle application

・Power conditioner

・ RF power supply

Choose the best digital isolator for your application.

[Introduction to Lineup Part 1] Analog Devices' Magnetic Isolation Method

Specifically, what kind of products do you have? This time, as the first part, we will introduce the former Analog Devices lineup using the magnetic isolation method.

Technological progress of the magnetic isolation method "iCoupler🄬"

ADI's digital isolator is called "iCoupler🄬". The iCoupler family has gained a reputation for its high robustness and noise immunity since its first generation, and has been installed in many medical applications and power conditioners.

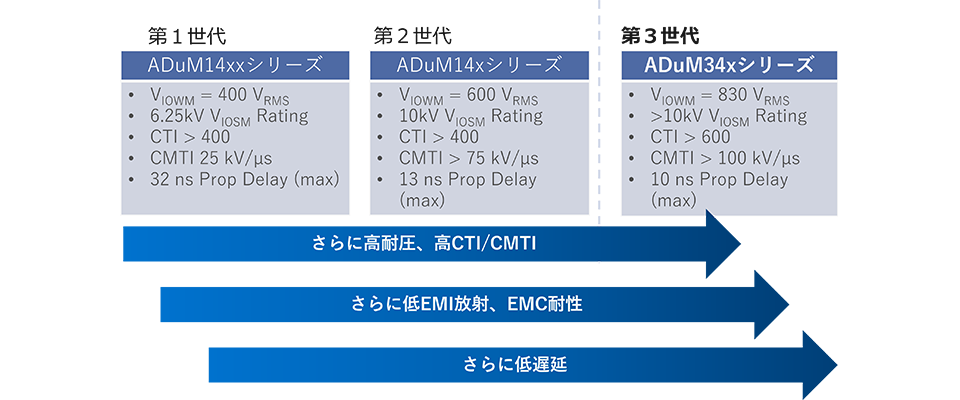

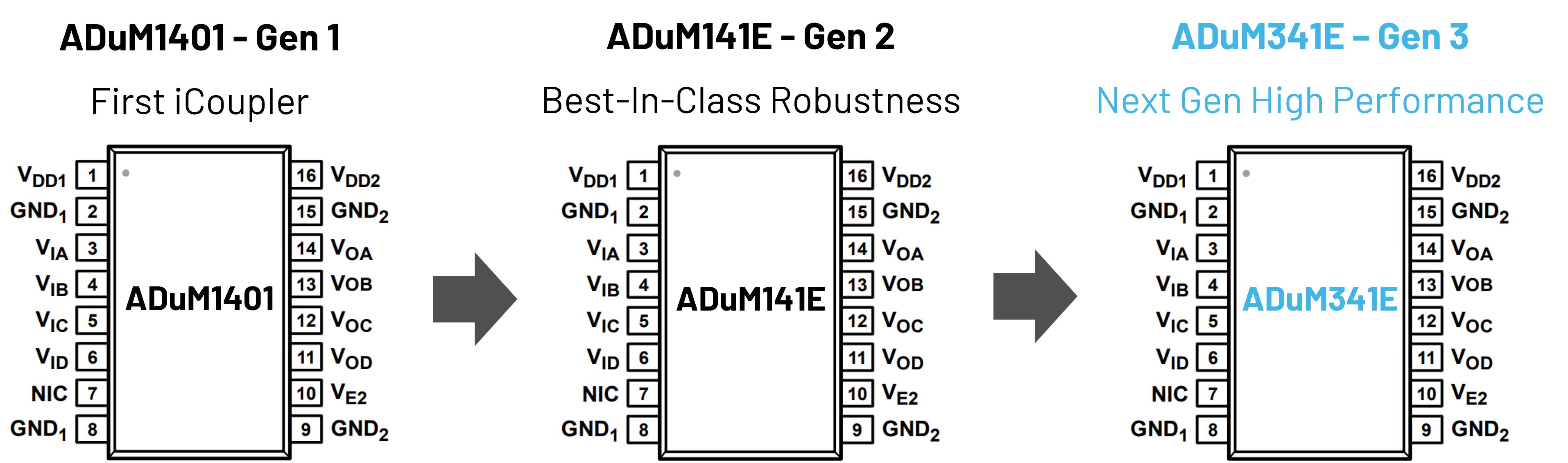

Technological innovation has been repeated with the advent of new generations, and the latest 3rd generation "ADuM34x series" has achieved even better performance in all aspects such as robustness, noise immunity, and transmission speed.

Can be replaced from the previous generation with pin compatibility

One of the features of the iCoupler🄬 family is that all generations of products are pin compatible. Customers already using 1st and 2nd generation iCoupler🄬 products can now adopt the latest 3rd generation technology simply by replacing the chip.

Medical and industrial equipment are often used for 10 or 20 years without changing their design. Even in such applications, the insulation performance can be reliably improved simply by replacing the chip. You can't afford not to take advantage of this advantage.

Excellent performance of the 3rd generation "ADuM34x series"

The table below compares the product performance of each generation. Green cells represent the best performance between generations. The 3rd generation is the best in most items, and you can see the high performance at a glance.

Particular attention should be paid to the safety, robustness and propagation delay parameters required by medical devices and industrial machinery. "Isolation Rating UL1577", "CTI", "Working Voltage (Viorm)", "CMTI (min)" and "Prop delay (max)" with slightly dark blue background in the table below are applicable. All in all, the performance of the 3rd generation stands out.

The 3rd generation ADuM34x series has performance that will greatly benefit not only those who newly adopt digital isolators, but also those who have used the 1st and 2nd generation iCoupler® family products. is evolving.

3rd generation standard digital isolator, ADuM34x series, updated in every aspect. Everyone, please take advantage of it by replacing it positively.

3rd generation standard digital isolator ADuM34x series updated in every aspect.

Replace everyone!

Application example

·Medical equipment

・Measuring equipment (separation of noise)

Click here to purchase products

Click here for manufacturer site/other related links

Inquiry

If you have any questions regarding this article, please contact us below.

Analog Devices Manufacturer Information Top

If you want to return to Analog Devices Manufacturer Information Top, please click the button below.