product

- Transportation/storage status monitoring and tracking service - Macnica Tracks® -

- Transportation/storage status monitoring and tracking terminal - Qualcomm® QTS110 -

- Location monitoring and tracking device - Qualcomm® QTS112 -

- [FAQ] Transportation/storage condition monitoring and tracking service - Macnica Tracks® -

- List of documents

Amendments to the Logistics Efficiency Act and measures that shippers should take: Are you leaving everything up to logistics companies?

Introduction: Amendments to the Logistics Efficiency Act

Logistics is an important social infrastructure that supports people's lives and economic activity. However, due to the effects of a declining birthrate, aging population, and labor shortages, it has been pointed out that the shortage of transportation capacity may become more serious in the future.

In light of this background, the Ministry of Land, Infrastructure, Transport and Tourism has revised the Logistics Efficiency Act and introduced a new framework aimed at sustainable growth in logistics.

This legal amendment has made it essential for not only logistics companies but also shippers to take steps to improve logistics efficiency. Macnica has already received consultations from various shipper companies about their issues.

From my perspective as a shipper, I would like to introduce this article to shippers who are planning to get started in this field.

|

From fiscal 2025, it will be an "obligation to make efforts" and from fiscal 2026, it will become an "obligation"

Source: Portal site for promoting understanding of the Logistics Efficiency Act https://www.revised-logistics-act-portal.mlit.go.jp/ |

Responsibility of specified business operators

"Specified Business Operators*" are businesses that are recognized as having a large impact on logistics as a whole, and are designated based on standards set by the government. (Specified shippers, specified warehouse operators, specified truck transport operators) These businesses have a responsibility to proactively promote initiatives aimed at improving logistics efficiency.

|

Key Takeaways |

|

If the company fails to comply with its obligation to make efforts, it may be penalized. |

The three main challenges shippers face and the risks that lead to management issues

Due to amendments to the Logistics Efficiency Act, shippers are now required to take responsibility for logistics management, but many challenges still exist in the field.

In particular, issues regarding "visualization and sharing of information" can be a barrier to complying with the law.

Macnica is also seeing an increasing number of shippers coming to us for advice on how to prepare for legal changes while also using technology to easily resolve quality control issues.

The issues that shipper companies consult us about can be broadly divided into three categories:

| ① Shippers can check directly No system |

Most logistics information is managed by the transport company, and shippers only receive reports. This means they are unable to grasp the transport status or abnormalities of their own cargo in real time, and they tend to respond after the fact. |

| ② In the digital tachograph Real-time confirmation is difficult |

Most conventional digital tachographs (digital tachographs) are designed to record driving operations. Because the data is collected after the vehicle returns to the warehouse, it is difficult to immediately identify any abnormalities during transportation and take preventative measures. |

| ③ Information is scattered, Cannot be comprehensively confirmed |

Information such as temperature, location, and impact is managed in separate systems, and there is no environment where all parties involved, including shippers and transport companies, can centrally grasp the overall picture. ▸ Various sensors and systems are independent, with no integrated view |

![]()

If not addressed, this could lead to the following risks:

| ① Check the status of your cargo In real time Unknown risks |

If incidents such as temperature deviations, shocks, and delays during transportation cannot be detected in real time, it can lead to quality deterioration and delivery delays, causinga loss of customer trust. |

| ② When an incident occurs "Reporting after the fact" is not enough |

If a problem is reported only after it has occurred, the initial response will be delayed anddamage will increase. Preventive measures and prompt corrective action are essential. |

| ③ Information for each department and contractor Divided"Siloization" |

If information is scattered across departments such as quality control, logistics, and sales, and across subcontractors, it will have a major impact on the formulation of overall optimization plans and performance evaluations that must be reported to the government. |

![]()

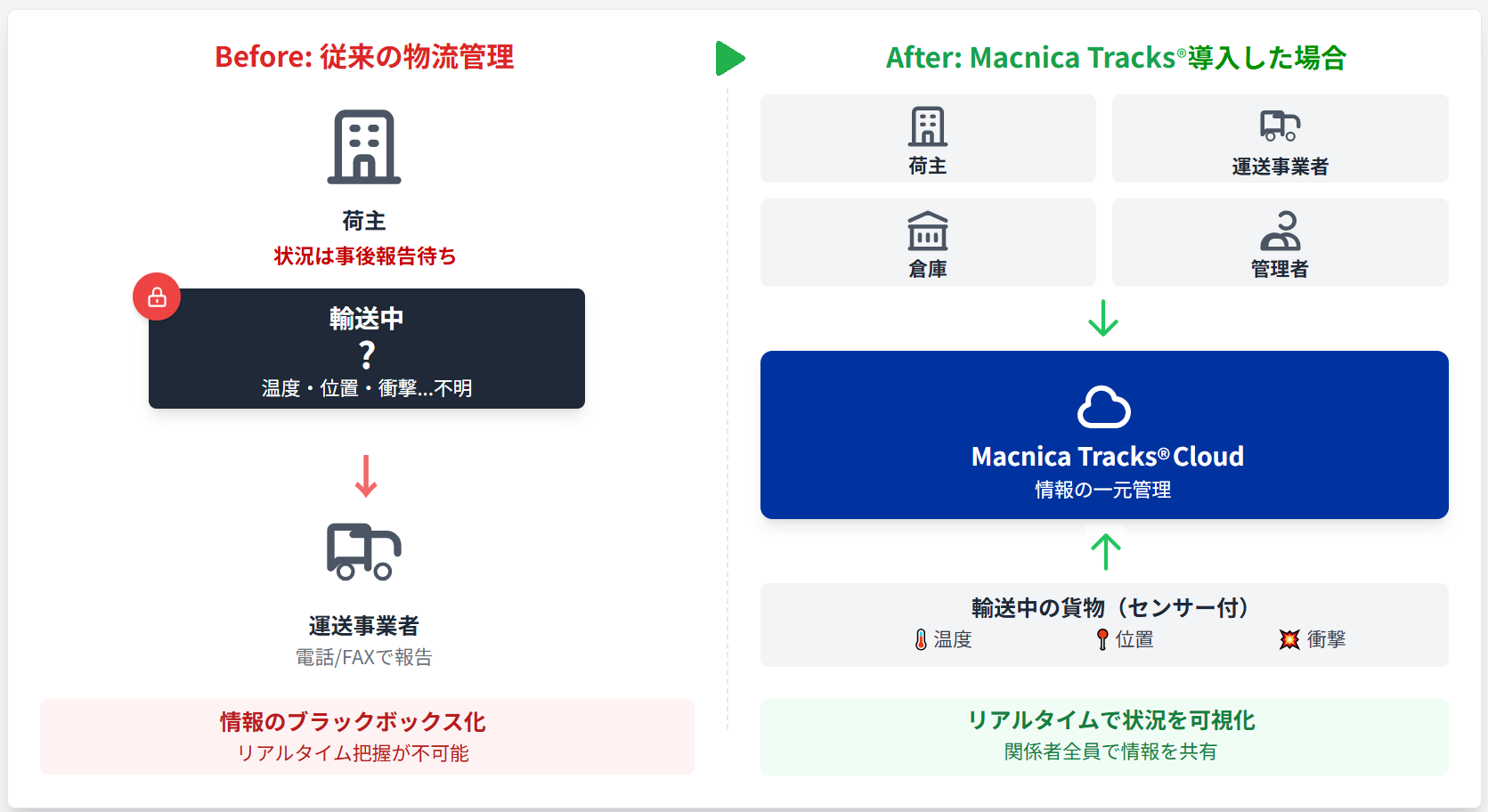

Macnica Tracks® can solve this problem! From fragmented, black Box logistics to a strategic supply chain connected by data

Three benefits that Macnica Tracks® can solve

Macnica Tracks® is a cloud-based monitoring solution developed by Macnica that realizes logistics visibility and efficiency.

We provide an environment where anyone, anywhere, can immediately grasp the "reality of the field", which was difficult to see with conventional logistics management.

Here are three benefits of Macnica Tracks® that solve the three challenges mentioned above.

| 1. Highly visible UI that anyone can use |

An intuitive UI (user interface) designed for a diverse range of users in logistics sites. No expert knowledge required, just a dashboard with important information (temperature, location, impact, battery level, etc.) Anyone can understand at a glance. ⇒ "An easy-to-use and easy-to-implement system that can also be checked by shippers" |

| 2. Cloud-based, real-time data viewing |

Data from sensor terminals is sent to the cloud immediately. Shippers and transport companies can simultaneously view the same information, and receive immediate alerts if an abnormality occurs. ⇒ "Real-time anomaly detection, immediate response, and information confirmation by the shipper" |

| 3. Permission management and device access restrictions enable information sharing among stakeholders |

Viewing and operation permissions can be set for each party involved, such as shippers, transportation companies, and warehouse operators. This enables smart information sharing, delivering only the necessary information to those who need it. ⇒ "Visualize the entire delivery process, and all parties involved share the same centrally managed data." |

Learn in 3 minutes! How to use Macnica Tracks® (video)

|

Finally With the revision of the Logistics Efficiency Act, an era has arrived in which shippers are also required to take responsibility for logistics management.

|

Related information External site links

For your reference, we have compiled some links below to information related to the Logistics Efficiency Act.

▼Outline of the revised Logistics Efficiency Act

https://www.maff.go.jp/j/shokusan/ryutu/attach/pdf/buturyu-606.pdf

○ Ministry of Economy, Trade and Industry website: About logistics efficiency

https://www.meti.go.jp/policy/economy/distribution/butsuryu-kouritsuka.html

○ Portal site to promote understanding of the Logistics Efficiency Act

https://www.revised-logistics-act-portal.mlit.go.jp/

▼About the "Explanatory Manual" and "Shipper's Pattern Collection"

○Commentary on shipper criteria

https://www.revised-logistics-act-portal.mlit.go.jp/files/pdf/sippers-judgment-criteria-book.pdf

○Shippers' thoughts on each logistics pattern

https://www.revised-logistics-act-portal.mlit.go.jp/files/pdf/sippers-mindset-logistics-pattern.pdf

○Commentary on shipper criteria

https://www.revised-logistics-act-portal.mlit.go.jp/files/pdf/sippers-judgment-criteria-casestudies-book.pdf

Inquiry

For any questions, estimates, or other inquiries regardingMacnica Tracks® introduced in this article, please contact us using the form below.