Okuma Corporation

Introduction facility overview

[Okuma Corporation Head Office Factory Facility Overview]

■ Location: 5-25-1 Shimokoguchi, Oguchi-cho, Niwa-gun, Aichi 480-0148

Total floor area: DS1 parts factory (12,300 m2), DS2 parts factory (11,000 m2)

■Neo cleaning area: DS1: 1,400 m2, DS2: 1,320 m2

■ Number of units introduced: 1 unit

Introduction background

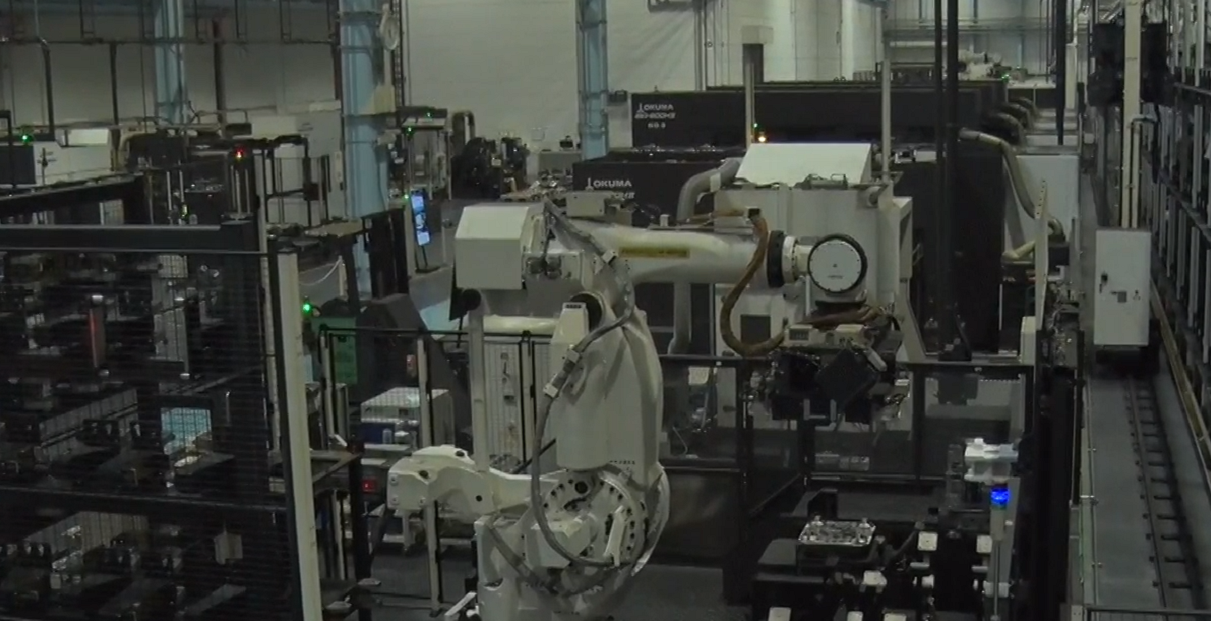

At the Aichi Factory, more than 80% of Okuma machines are in operation, promoting efforts to become a smart factory.

One of the challenges was to maintain and improve the working environment for the realization of diversity, and to keep the floor clean in the sense of welcoming customers who visit the factory tour.

Until now, managers used ordinary floor cleaning machines to spend time cleaning, but we thought that if we could automate cleaning, we would be able to focus more on high-value-added work and increase productivity.

In addition, the workplace environment will become cleaner than before, and we expect secondary effects such as thorough implementation of 5S and safety by leading to the awareness of maintaining a clean environment.

interview

Points emphasized in selecting a robot

One of the features of Neo is that it not only wipes clean, but also picks up dirt without damaging the floor. In addition, until now, we used diluted detergent, but Neo has the cleaning power to clean even without using detergent. I feel that this is also very good in terms of reducing the impact on the environment.

In addition, the same area can be cleaned in about half the time compared to conventional cleaning, and even if cleaning is done in the same time, the number of cleanings will be doubled, so the cleaning effect will be enhanced. I'm here. Introducing Neo to automate floor cleaning and reduce the impact on the environment is effective in terms of letting people know that Okuma is working on SDGs as well. I don't think so.