One-stop solution for embedding AI x IoT in machine tools

We will help you provide high value-added products to your customers by incorporating cutting-edge technologies such as AI and IoT.

With the advancement of IoT, there is a need to not only "connect" various machines, but also to provide new value by utilizing the data obtained from them. It is necessary not only to sell machine tools individually, but also to provide added value to solve problems at manufacturing sites, such as reducing downtime, optimizing maintenance costs, and increasing the efficiency of work processes.

Macnica leverages its experience in solving problems in the manufacturing industry and has the know-how and cutting-edge technology to solve problems for machine tool manufacturers and end users.

We support the creation of solutions suitable for various machine tools, from demonstration experiments to commercialization and maintenance operations, contributing to the creation of new business models.

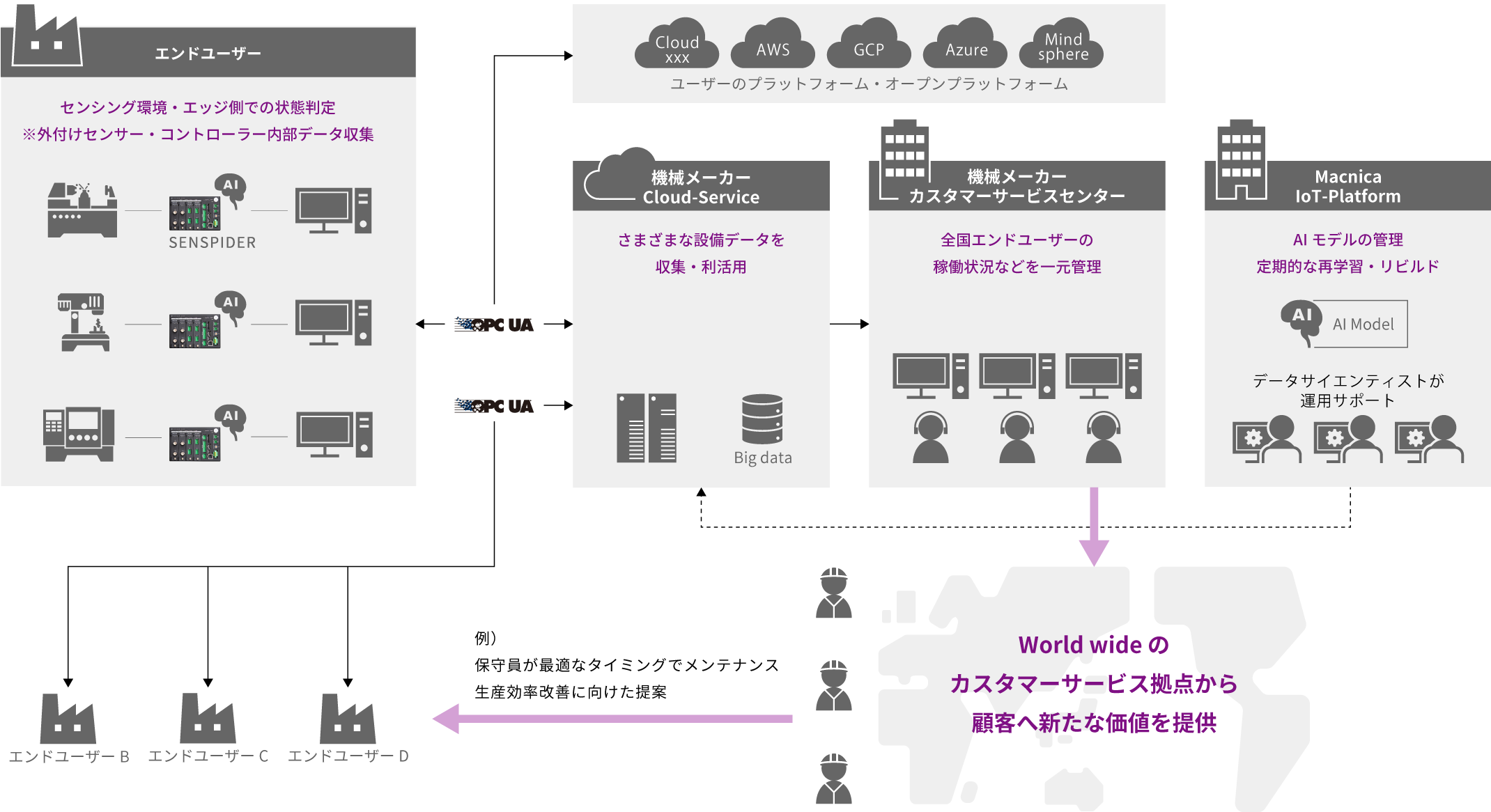

System image Process integration

By utilizing technologies such as AI and IoT to aggregate data not only for machines but also for the entire factory, we are able to monitor and optimize the operational status of all factories around the world.

By aggregating and visualizing the acquired data in the cloud system, continuous maintenance can be provided to end users.

Do you have any problems?

I have to work on product development using advanced technology, but I don't know where to start

I want to know the status of AI efforts by machine tool manufacturers

You cannot introduce AI on your own

We want to provide customers with products with high added value

Machine Tools Typical Issues by Type and Approaches to Solutions

Different types of machine tools have different ways of solving problems.

We use the latest and most suitable technology for various machine tools to solve problems and support process optimization.

Types and issues |

ダウンタイム削減 |

Machining precision abnormality detection |

|---|---|---|

lathe |

Spindle predictive maintenance |

Tool error/wear detection |

Grinder |

Spindle predictive maintenance |

Whetstone abnormality (clogging, crushed eyes, spilled eyes) |

gear cutting machine |

Spindle predictive maintenance |

Tool error/wear detection |

machining center |

Captured during warm-up |

Tool error/wear detection |

electrical discharge machine |

Table ball screw predictive maintenance |

Coolant discharge monitoring |

Injection molding machine |

Ball screw/motor predictive maintenance |

Screw wear detection |

final goal

- Automatic recommendation of optimal machining parameters for input drawings

- Remote process error cause detection, remote maintenance

- Real-time feedback to machining conditions with machine condition sensing

- Index position optimization

Building AI-powered solutions that are valuable to end users

Supporting business model transformation itself for machine tool manufacturers

Okamoto Machine Tool Mfg. Co., Ltd. Effort example

``Aiming for a grinder that anyone can easily perform high-precision machining, approaching the behind the scenes of the development project''

One-stop solution for embedding AI x IoT in machine tools

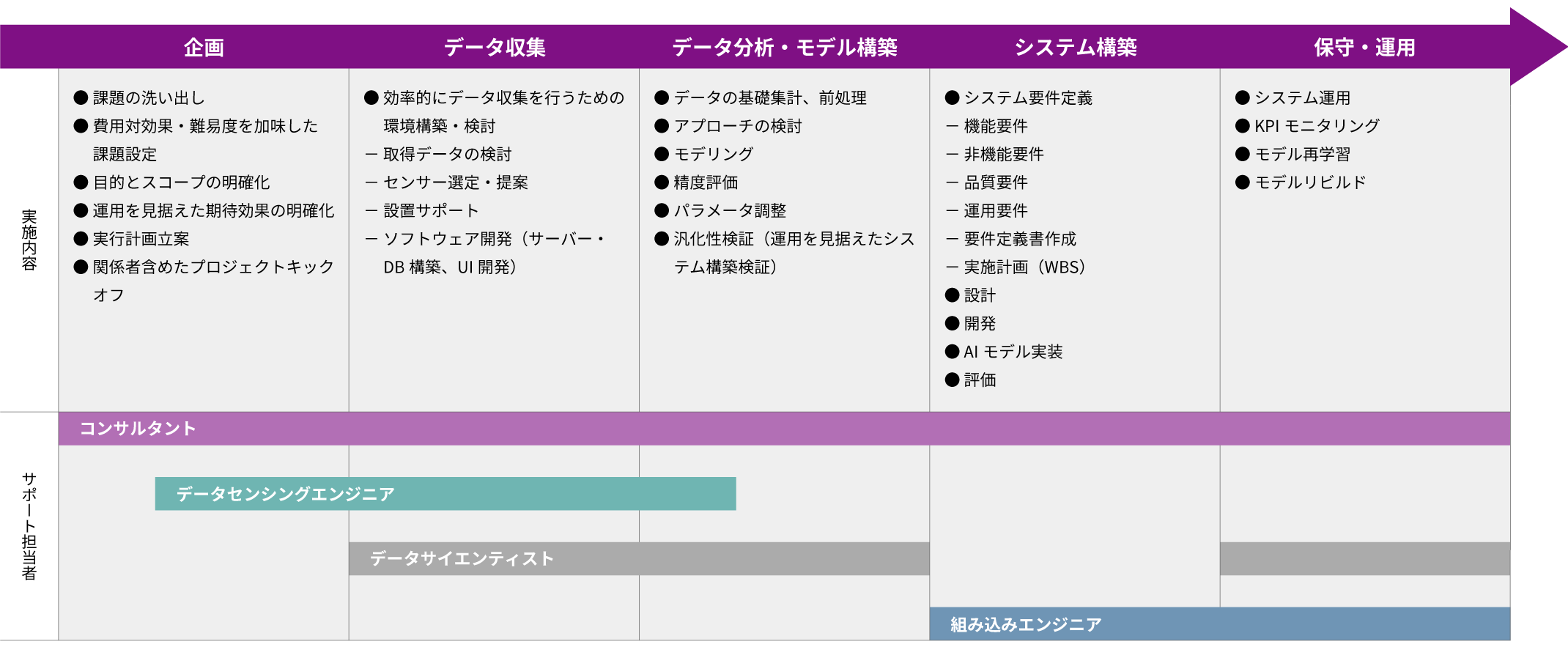

How to proceed with a machine learning project and support system

In order to provide high value-added machine tools to end users, it is essential to introduce technologies such as AI and IoT.

However, this requires a support system with specialized knowledge in each phase.

Macnica has specialists such as data scientists and data sensing engineers who will accelerate the resolution of our customers' problems.

Macnica 's strengths

01 Sensing technology

Support for effective data collection according to equipment by engineers from the manufacturing industry who are familiar with on-site equipment

- Consulting on appropriate sensor selection and mounting position

- Utilization of CNC/PLC data in equipment

02Data analysis and AI implementation technology

E (Engineer) qualification specializing in solving problems in the industrial equipment and manufacturing industries * Support by a possessed data scientist

- Optimal Algorithm Selection for Problems - AI Generation, Device Implementation

- Algorithm tuning according to a wide range of user environments (instrumental differences, machining conditions, target workpieces, etc.)

A wide variety of mounting destinations

- Wide coverage from edge computing terminals and industrial PCs to component level (CPU, PGA, GPU)

*Qualification E: A person who understands the theory of deep learning and has the ability to select and implement appropriate methods, certified by the Japan Deep Learning Association.

03Incorporated support centered on our own products, unique to technology trading company Macnica

Adopting trends in cutting-edge technology, commercialization, and incorporation of AI IoT into mass-produced equipment

- Semiconductor sensor-based low-cost, waterproof, compact vibration pickup “AVP”

- Sensor data collection Edge computing terminal ”SENSPIDER”

- Original OPC UA Server SDK (Industrie4.0 compliant)

Technical Exchange Meeting 2020 Lecture Report

"Digital Transformation of Machine Tools and the Road to Service to Generate New Revenue Sources" was held.

What is the transformation of machine tool manufacturers from selling products to selling products using digital technology?

You can see the materials of the session on the day.