The other day, we invited a machine tool manufacturer with whom we have a relationship and held a technical exchange meeting.

The technology exchange event will consist of the following four programs, and here we will introduce the contents of the third program, "[Lecture by Macnica Engineer] Key Technologies Driving Digital Innovation."

Also, the materials for the day are here It can be downloaded from.

*Input of personal information is required to download materials.

1. EMO Blog ① (3 times in total)

2. Participatory panel discussion] Industry key figures approach the essence of digital innovation in machine tools

3. [Lecture by Macnica Engineer] Key technologies driving digital innovation

Four. [Special Lecture] Fighting the world through value change - How we were able to transform from Ise's long-established restaurant "Ebiya" to one of the world's leading AI companies "EBILAB" -

Lectures by Macnica engineers were given on the following three themes.

① Impact of 5G on the manufacturing industry

② Solving the generalizability problem with self-learning AI and business model reform starting with AI implementation

3) The essence of vibration sensing as seen through examples

(1) Impact of 5G on the manufacturing industry

About 5G

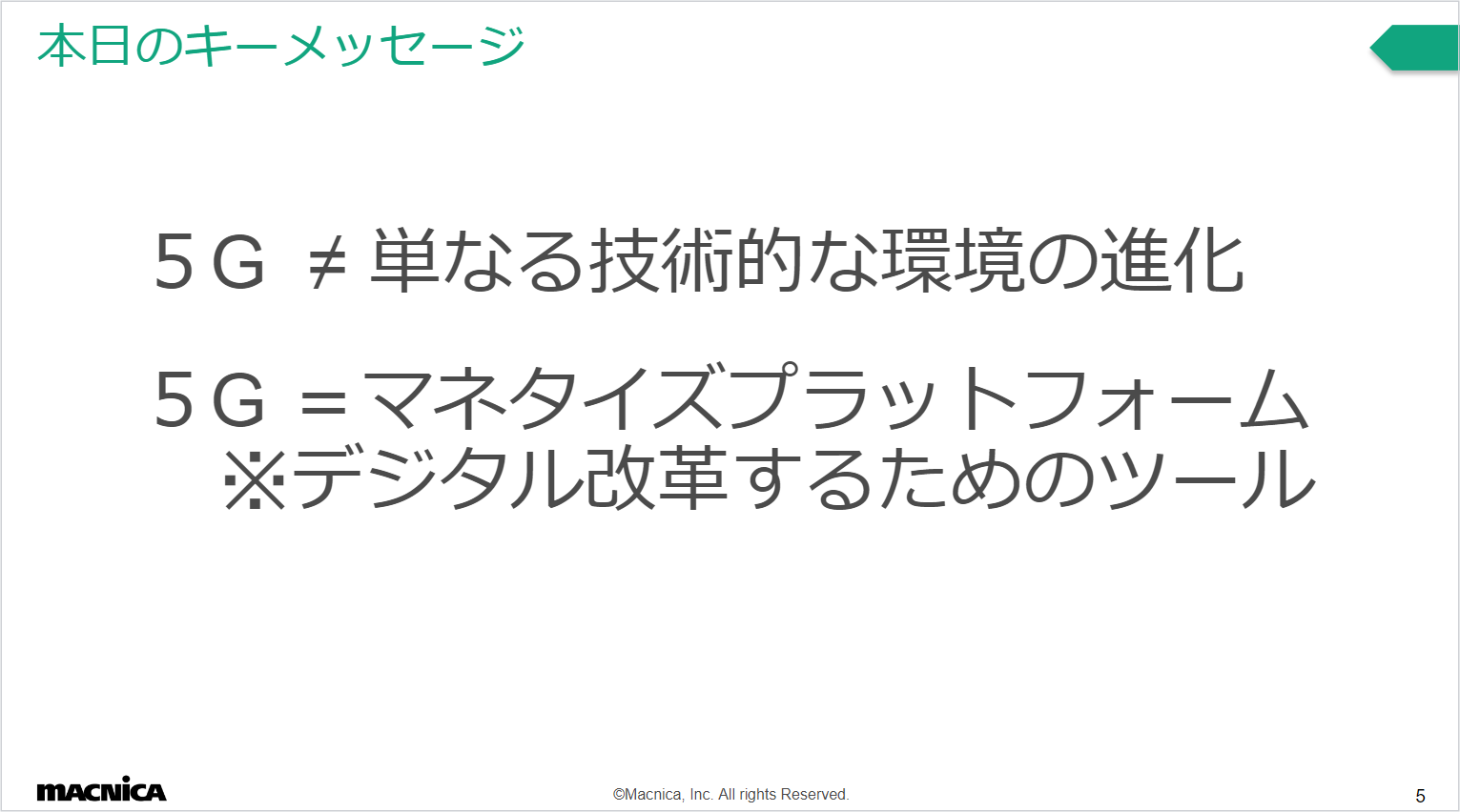

Last fall, 5G was used at rugby match venues to enable multi-angle viewing, and the use of 5G has begun worldwide.

Major changes from 4G to 5G include high-speed, large-capacity communication, the possibility of multiple simultaneous connections, and high reliability. It is expected to become a monetization platform for

Needs for digitization of manufacturing sites, the actual state of wireless utilization, and future utilization methods

One of the current trends in the manufacturing industry is the shift from mass production and high-mix low-volume production to variable-variety variable-volume production.

In the midst of this trend, there is a demand for greater efficiency through the digitization and wirelessization of manufacturing sites.

However, the challenges of using wireless in industrial networks are the latency and lack of reliability compared to wired networks.

By utilizing 5G, it will be possible to achieve low latency and improved reliability.

Furthermore, implementation of a standard called IEC/IEEE60802 TSN (Time Sensitive Network), which synchronizes the time of machines in a factory, is also under consideration.

In addition, by adopting local 5G, it is possible to flexibly build according to individual needs, and compared to the services of telecommunications carriers, a network environment that is less susceptible to communication failures, disasters, network congestion, etc. in other locations. will be able to build

We believe that the use of 5G can promote smart factories.

(2) Resolve generalization problems with autonomous learning AI and reform business models starting with AI implementation

Wall of Generalization and Autonomous Learning AI

Efforts to utilize AI at manufacturing sites are spreading, but although it works well at the stage of proof-of-concept (PoC), at the actual manufacturing site, the AI model created by PoC is affected by differences in tools, disturbances, etc. There are many cases that cannot be handled.

As a solution, there is a method of having AI learn various patterns, but the AI model becomes larger and more complex, and experience shows that it is almost impossible to learn all situations.

This is called the generalization wall.

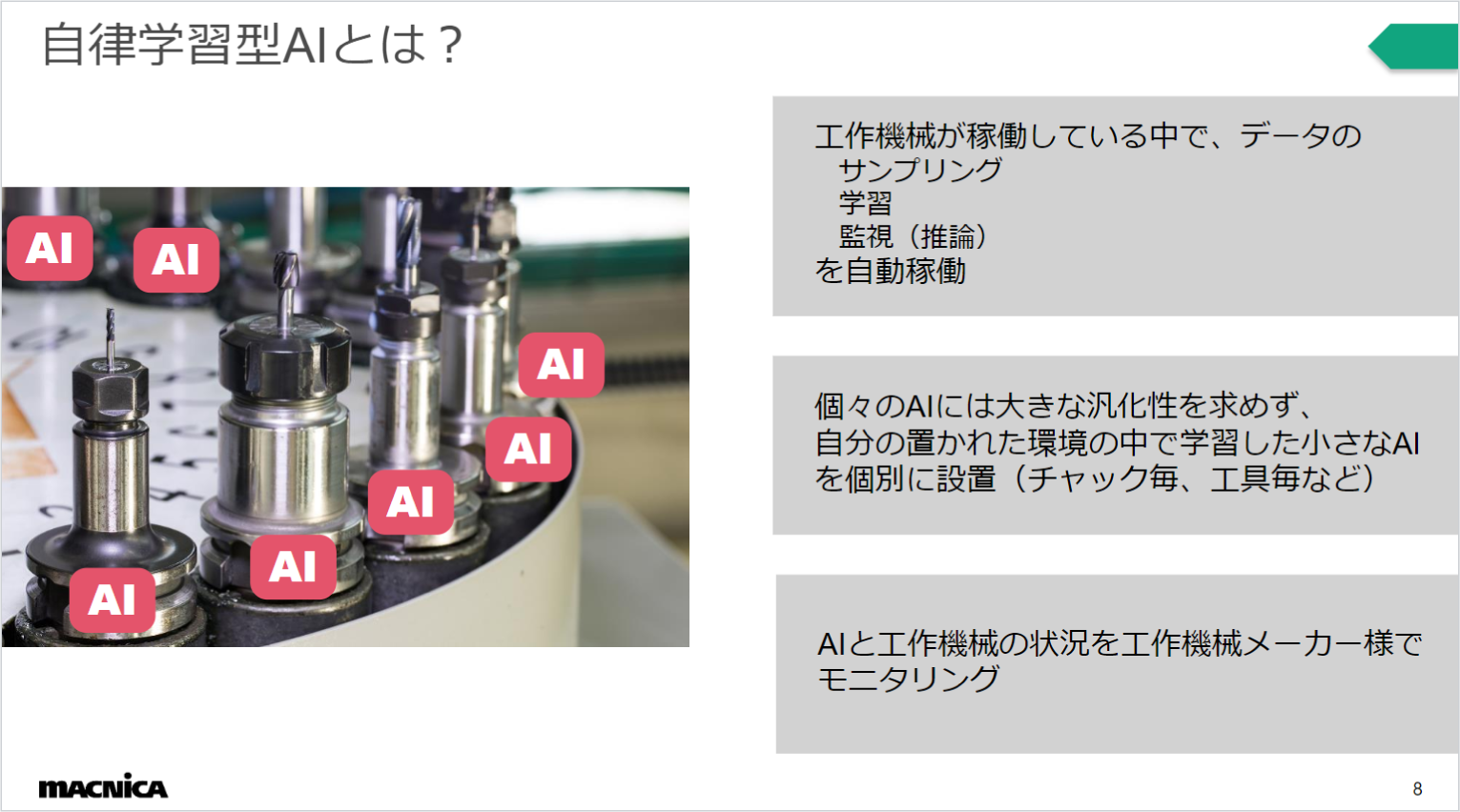

As a solution, we combine multiple small AIs that operate only in limited environments such as tools and chucks in machines, and utilize autonomous learning AI that continues to automatically learn each environment for each AI. I think we can do it.

Business model reform starting with AI implementation

In order to make autonomous learning possible, the knowledge of machine tool manufacturers is essential to mastering AI, such as data sampling methods such as which data to acquire and how to acquire, and evaluation of results inferred by AI. increase.

Furthermore, the implementation of autonomous learning AI means that the machine tool manufacturer can acquire and accumulate the operating status of the end user.

If we can have this data, we believe that it is possible to change the business model from selling machine tools to a service that sells machine tools themselves.

(3) Essence of vibration sensing seen from examples

Providing new value by applying AI/IoT to machine tools

With the progress of IoT in factories, there is a demand not only for various machines to be "connected", but also to provide new value through the utilization of data, such as reducing downtime, optimizing maintenance costs, and detecting abnormalities in processing accuracy.

In order to realize these, there are increasing cases where vibration sensors are attached and sensed to grasp various conditions.

This is because defects in dynamic equipment often appear as changes or increases in vibration.

Vibration sensing case study

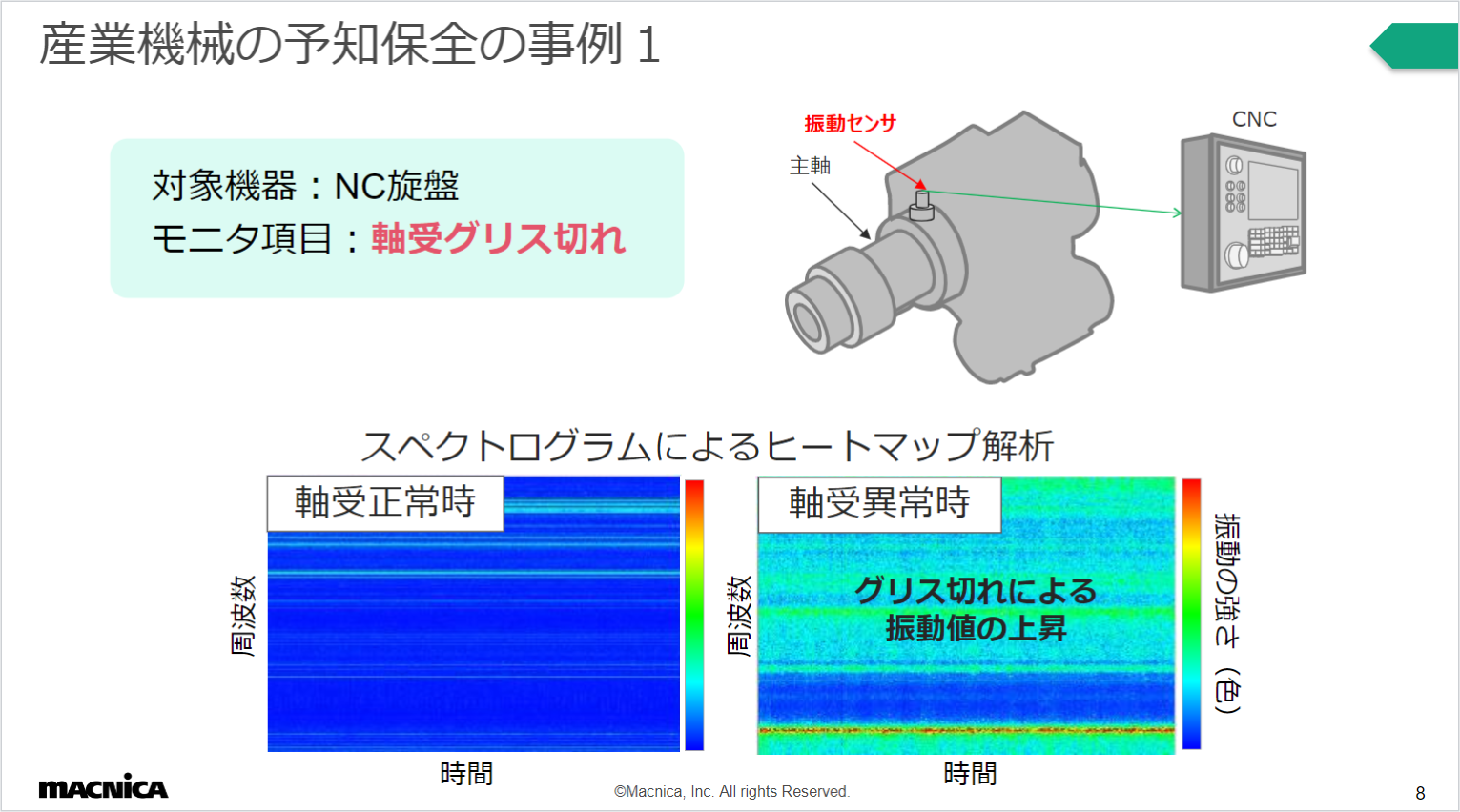

For example, in the predictive maintenance of industrial machinery, there are examples of using vibration sensors to detect running out of bearing grease on NC lathes and defective tools on milling machines.

Vibration sensing data contains information on various events in addition to information on abnormalities and defects, so there is variation in the data.

In addition, since there is also an effect of the installation location, those points are also necessary.

Acquiring data correctly (considering in advance how to acquire and use data) can be useful in various situations such as anomaly detection.