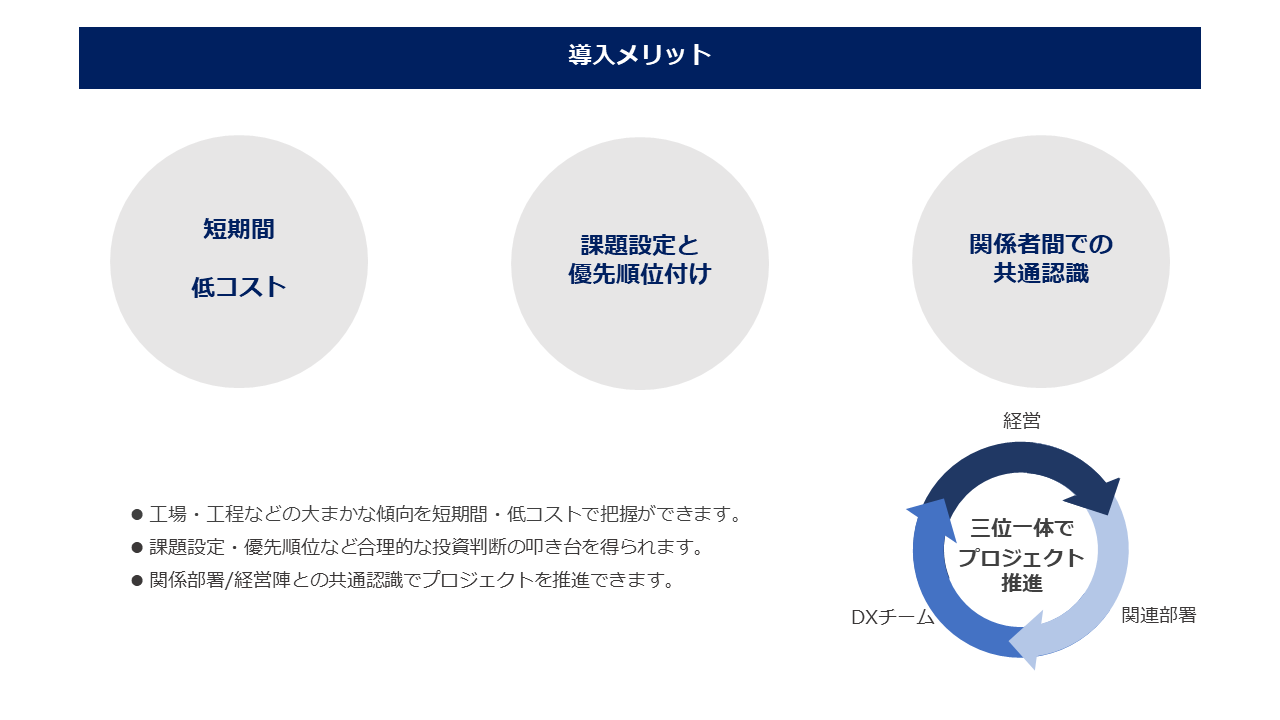

The digital factory introduction support service is a service that builds a model of an actual factory in the digital space of a computer with an accuracy of 70-80%.

Bottleneck analysis at the manufacturing site, visualization of issues, and prioritization can be performed in a short period of time.

By using a simulation model, it becomes a communication tool that connects the field and management, and is useful for making accurate investment decisions.

What is Digital Factory Introduction Support Service?

This is a service that uses the simulation software "Siemens Plant Simulation" to build a model based on factory data.

By performing simulations based on the created model, it is possible to grasp the current state of the factory and general trends. A big advantage is that it can be converted.

In addition, related departments promoting the DX project will be able to grasp the whole, set issues, and make investment decisions based on common data.

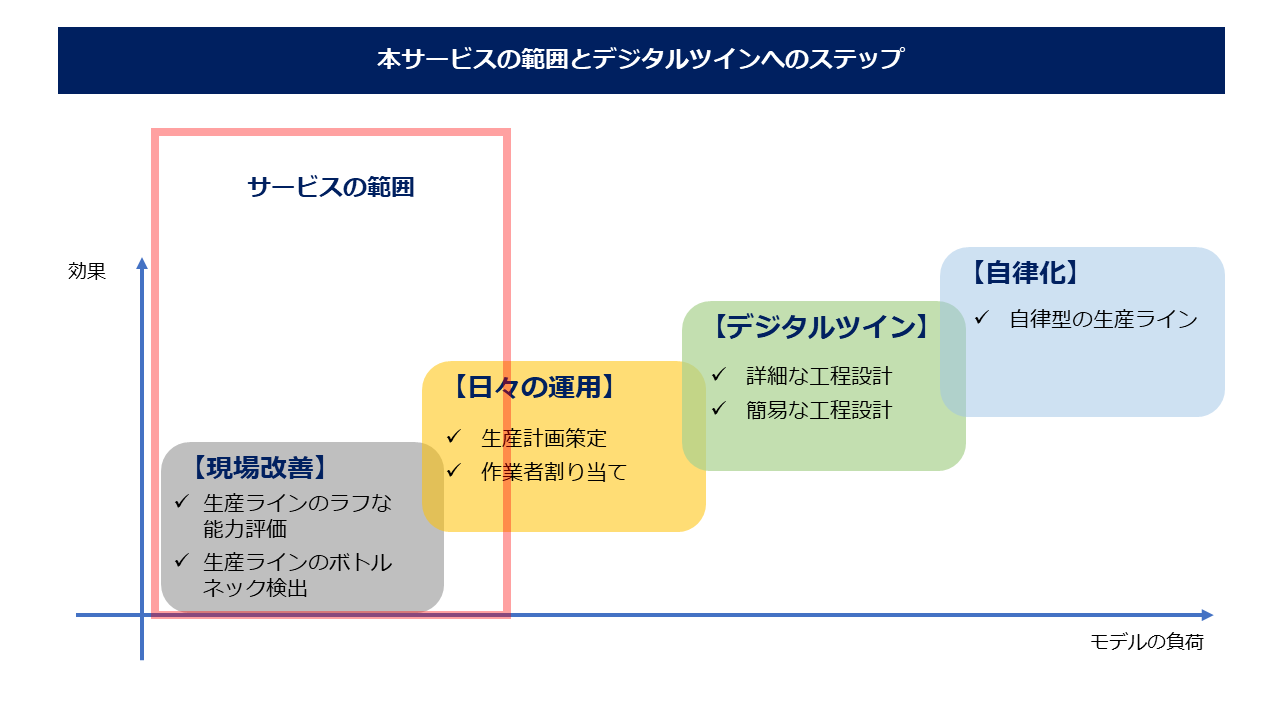

This is the first step to utilize and operate a digital twin in-house, and based on the basic model created by this service, continuous operation by the customer will help create a flexible factory that can withstand demand fluctuations. .

Service details

Based on the premise that the accuracy will be gradually improved from a rough overview, we first build a rough factory model as a foundation.

By simply preparing the necessary data, the customer can reproduce the actual factory model in the digital space with an accuracy of 70% to 80%.

| Visualization item example | Eligible *1 | Deliverables | Amount *2 | Model creation period *3 |

|

・各設備の稼働率 ・Flow rate curve ・Interim inventory ・Equipment logs ・Work log |

・Processing and assembly factory ・Only in the process |

·model ・Report |

~1.2 million yen |

2 weeks~ |

*1 We will determine the scope of support through free counseling.

*2 Special processes may incur additional costs. License fee not included.

*3 It may take some time to confirm the data. Special cases may take longer. It may take some time to start creating the model

Input data example

| Data required for model creation * |

|

・Layout information ・Process information ・Workflow (how many items flow) ・Processing time of each equipment ・Set-up time, timing ・Manual work data |

*Please enter data according to the format provided by Macnica. The required data will vary depending on the customer's request. Details will be determined during counseling.

Steps to digital twin using this service

We will prepare an environment for data acquisition starting with high-priority issues, and aim for a digital twin in the future to realize a flexible factory that is resistant to change.

Inquiry

Start with free counseling. Please feel free to contact us!