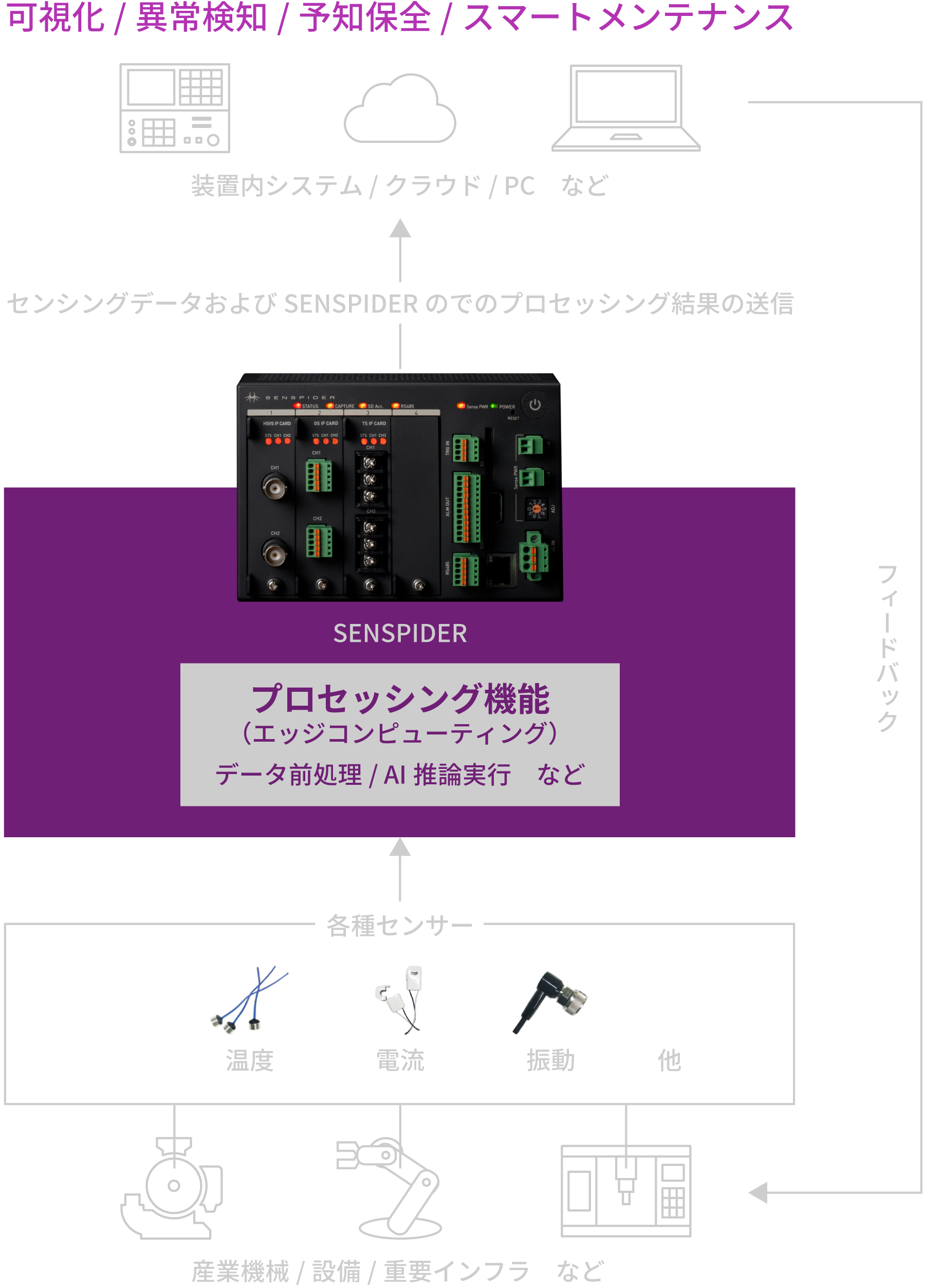

Start with smart sensing

smart maintenance

Are you spending more time and money than necessary?

With SENSSPIDER

Smart maintenance system (CBM system)

Simple and easy to build

Broadband vibration sensor data acquisition, data preprocessing,

Until the implementation of the user's original AI inference model,

Develop quickly and efficiently

WHY SENSPIDER?

Downtime reduction

Before

Prolonged downtime due to machine stoppage, loss of production plan

After

SENSPIDER monitors abnormal signs and realizes predictive maintenance

Maintenance cost optimization

Before

Retain parts with regular parts replacement

After

Minimize parts replacement by grasping equipment status with SENSPIDER

Waste reduction

Before

Unintentionally defective products occur during manufacturing due to sudden abnormalities

After

Eliminate defective products by detecting abnormalities in advance with SENSPIDER

automation/autonomy

Before

The problem with automation is that it is not possible to detect anomalies that humans have been able to detect up until now.

After

Solved by constantly monitoring conditions with SENSPIDER

FEATURE

Compact enough to forget its existence.

Above all, it's easy.

Edge computing is here.

We are proud of our extensive coverage.

surprisingly affordable.

PROCESSING

What's Processing Function?

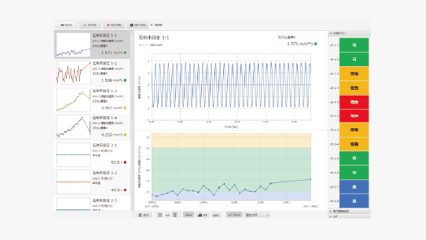

It can be used for various processing purposes, from user original AI model implementation to feature value implementation without programming.

It is a friendly function for specialized engineers in various fields.

Resources

USECASE

Ability to develop functions such as anomaly detection and predictive maintenance

![[For PC] For machine tool and industrial machine manufacturers](/business/ai_iot/products/hardware/senspider/image/senspider_usecase_draw01.svg)

![[For smartphones] For machine tool and industrial machine manufacturers](/business/ai_iot/products/hardware/senspider/image/senspider_usecase_draw01_sp.svg)

Improve detection accuracy of anomaly detection and predictive maintenance

![[For PC] Improve detection accuracy of anomaly detection and predictive maintenance by using IoT x AI Ready Platform](/business/ai_iot/products/hardware/senspider/image/senspider_usecase_draw02.svg)

![[For smartphones] Improve detection accuracy of anomaly detection and predictive maintenance by using IoT x AI Ready Platform](/business/ai_iot/products/hardware/senspider/image/senspider_usecase_draw02_sp.svg)

For anomaly detection and predictive maintenance using IoT and AI

PLC and NC data can also be collected

white paper

Predictive maintenance and anomaly detection projects

basics and points

USER