SENSPIDER embedded development PoC kit for industrial machine manufacturers

Ideal for function development of anomaly detection/predictive maintenance using AI in industrial machinery!

By incorporating SENSPIDER into your product, you can shorten the development period.

- Bearing scratches/wear

- Abnormal spindle

- shaft unbalance

- ball screw failure

- Abnormal tool/chattering

- heat mutation

machine tools, press machines, injection molding machines,

Semiconductor manufacturing equipment, industrial printers,

Large boilers, pumps, compressors,

Centrifuges, cooling towers, conveyors, etc.

Device with rotating mechanism

Representative function

- Reducing the number of consecutive defective products caused by abnormal alarms

- Maintenance optimization by detecting signs of failure

- Accuracy improvement by monitoring the condition of important points

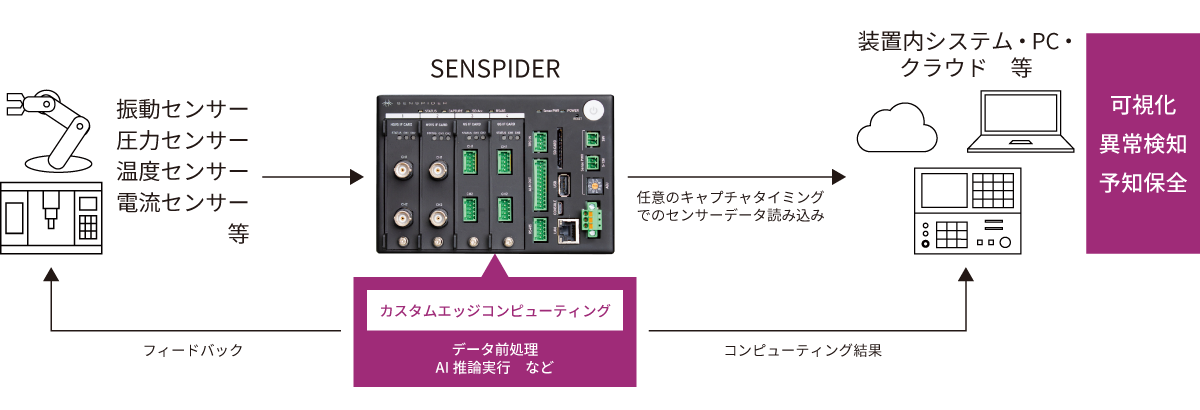

System configuration

Data from various wired analog sensors can be acquired with a simple configuration

Wideband vibration sensor compatible (up to 48KHz sampling)

User custom AI models can be implemented

Predictive maintenance / Milestone of embedded development of anomaly detection function

In addition to SENSPIDER 's technical support, please entrust us with commissioned development in each phase.

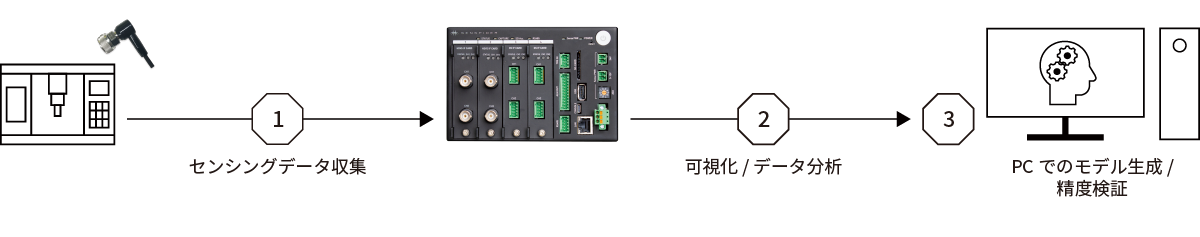

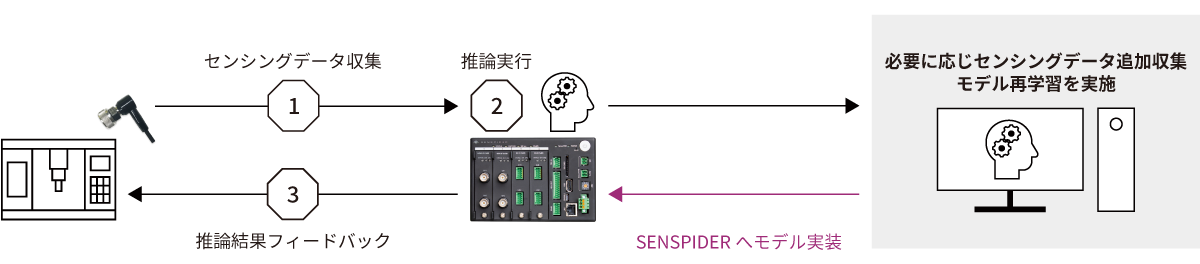

System configuration for each phase

Phase 1-2 Data accumulation - model development / accuracy verification

Phase 3-4 Construction of actual machine verification environment - Product development

Kit contents

1. Sensor data collection unit

feature

■ All-in-one functions required for sensor data collection (sensor power supply / sensor amplifier / data logger / computing / communication interface)

■ Width 150mm x Depth 85mm x Height 100mm Neatly stored in the control panel

■ Realizes data extraction with various capture modes/trigger functions

■ 3 interface cards can be freely combined (up to 8ch input possible)

■ Edge detection is possible on SENSPIDER by implementing a user custom algorithm

Interface card specifications

2. Data analysis software Sigma

feature

■ Management of time-series data obtained in cooperation with SENSPIDER / waveform display / signal processing / trend display, etc.

■ General text format measurement data collected by devices other than SENSPIDER can also be imported

■ Supports data analysis using the MT method using the AI module function (when the AI module option is selected)

Waveform display

FFT

spectrogram

envelope

kit price

| SENSSPIDER |

| 3 sensor interface cards *selectable from high-speed vibration/general-purpose/temperature |

| 5 years maintenance |

| Data analysis software Sigma *Optional |

| PoC kit for industrial machine manufacturers |

¥400,000 (excluding tax) |

| PoC kit + Sigma option for industrial machine manufacturers |

¥900,000 (excluding tax) |

*可視化、データ分析用のPCは納品物に含まれません。

*Consultation and installation for data acquisition/analysis are not included in the package.

* Sigma is the software that analyzes the acquired data. It cannot be used for long-term continuous operation when incorporated into a system.

Inquiry

Related product

*"SENSPIDER" is a registered trademark of Macnica