Siemens Plant Simulation

Plant Simulation is a simulator that can digitally reproduce and verify everything related to the production process.

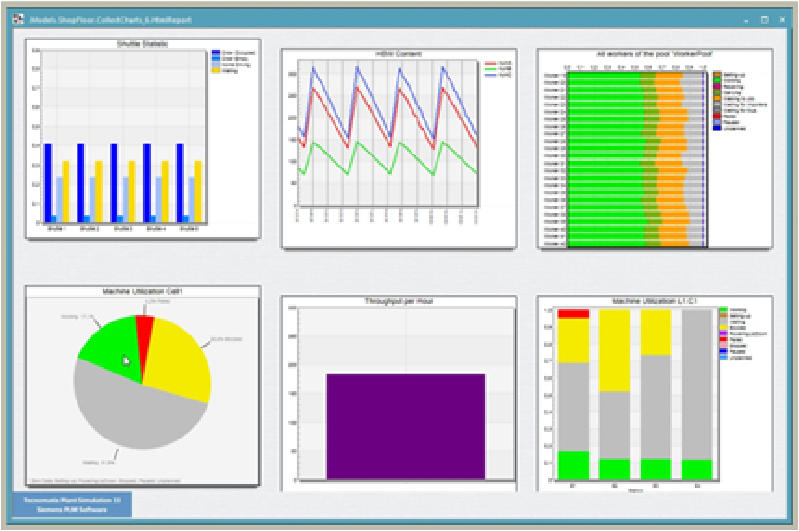

By using simulation software, it is possible to simulate the flow of goods and people, and visualize and optimize factory KPIs.

From production equipment in factories around the world to specific lines, we can flexibly respond to all kinds of factory plans, improve productivity, improve the utilization rate of equipment and people, find and improve bottlenecks, and reduce inventory. To do.

By reflecting the simulation plan in the actual factory logistics and continuing to compare hypotheses and results, it is possible to continue to improve the most efficient factory logistics process.

You can solve these problems!

By reproducing the factory in virtual space, it is possible to verify various manufacturing performance digitally before implementing improvements in the real factory. This is also valid for bottleneck analysis in 4M. In addition, it is possible to repeat hypothesis verification in any number of patterns to achieve KPIs such as production volume and delivery date.

An example of problem solving

It is possible to solve such problems that occur in the factory.

Inventory optimization

"when" "where" "how much"

Visualize and analyze whether parts and work-in-progress are generated

overstock

Possible to reduce!

When starting up a new factory/new line

Layout, number of equipment,

Verification of various items such as the number of workers

Immediately after launch

Realization of highly productive factories and lines

Verification of personnel resources and allocation

Optimal allocation of personnel resources and

Verifies the number of people and shifts

Reduce waiting time and

Leads to maximum utilization of personnel resources

Drafting of production plans

Take advantage of automatic optimization

For drafting production plans

of complex production planning work

Reduction of time and elimination of dependence on individual skills

Features of Plant Simulation

Various factory models can be created flexibly

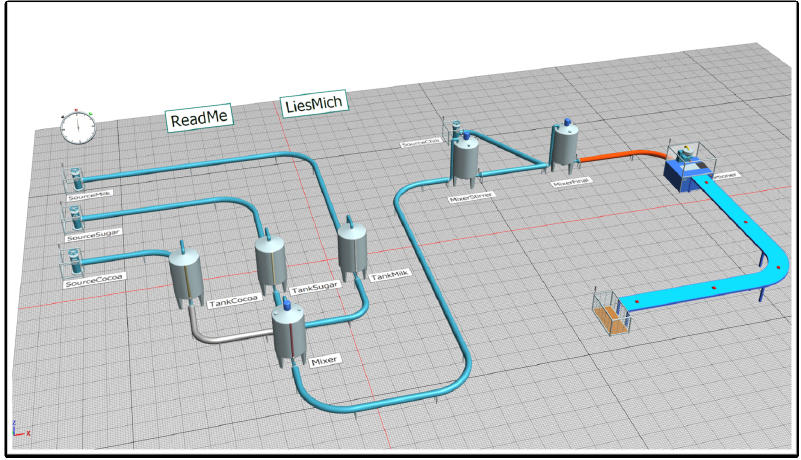

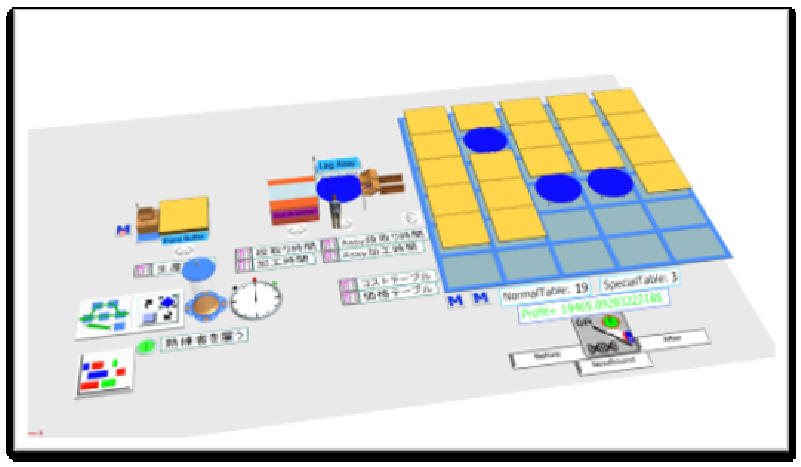

By simulating various factories, it is possible to visualize the entire factory, facility operating rates, inventory fluctuations, etc. It is possible to reproduce and simulate factories in various industries such as processing and assembly processes and fluid processes.

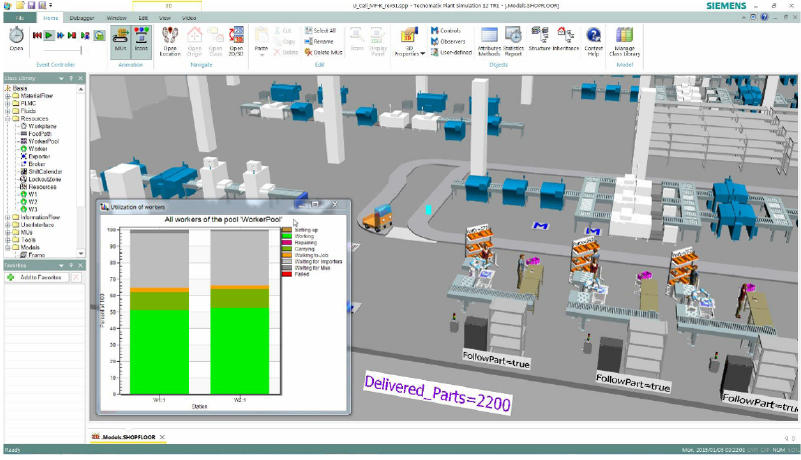

The effects of simulation are demonstrated not only in automated lines with equipment, but also in human work, line processes, and cell processes.

As long-term simulations such as 1 day, 1 week, 1 month, and 1 year can be executed in a short time, it is possible to verify what kind of things can happen under what conditions during production. can lead to action.

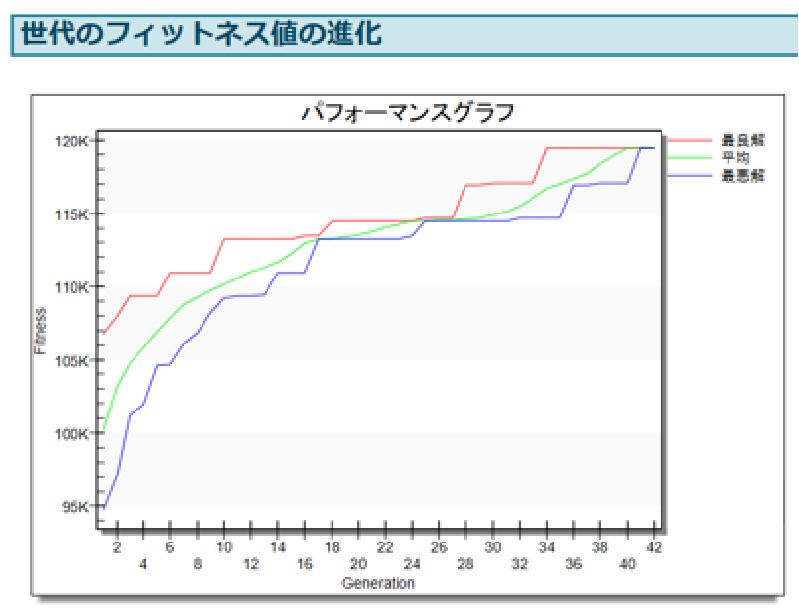

Automatic optimization function

The automatic optimization function* of Plant Simulation is a function that utilizes a genetic algorithm (GA) to calculate the value closest to the optimal solution from among a huge number of simulation patterns. By using this function when performing a simulation with a huge number of combinations, it is possible to derive which pattern is closest to the optimal solution.

By applying this function, you can also use it for planning production plans.

*Professional license only

Various functions and interfaces

Equipped with analysis tools such as automatic bottleneck analysis, distribution line diagram, and Gantt chart.

Since there are various interfaces, it is possible to link not only with Excel, but also with databases and core systems.

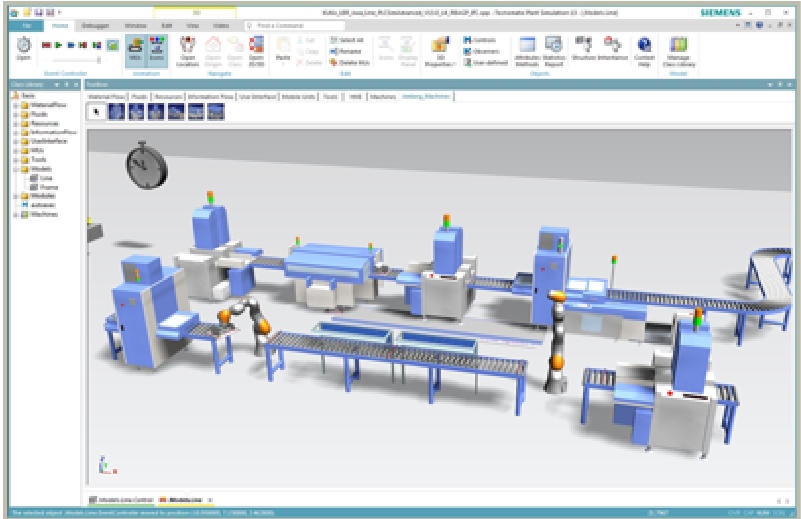

3D visualization

The simulation is not limited to 2D images, but 3D image display that is closer to the actual site is also available.

Simulation in 3D makes it easier to visually communicate, so it can be used as one of the materials for proposals and explanations. CAD data can also be imported, so it is possible to simulate the appearance of a real factory.

Introduction flow

| How to proceed with the project |

service |

|

| -Phase 1- simulation Utilization plan |

Grasping of current issues/examination of simulation effects/selection of optional services/cost estimation |

consulting |

| ▼ | ||

| -Phase 2- Process information arrangement of |

Process information (flow, layout, etc.) / Equipment information (processing time, setup time, etc.) / Worker information (number of people, role, etc.) |

consulting |

| ▼ | ||

| -Phase 3- simple model Design of |

Objective setting / Functional design / Model design / Review |

model development |

| ▼ | ||

| -Phase 4- simulation Software introduction |

Select a simulation software license that matches your application |

simulation |

| ▼ | ||

| -Phase 5- exercise training |

Usage Training / Model Design Method Training |

manufacturer training |

| ▼ | ||

| -Phase 6- simulation Utilization/Operation |

Technical FAQ / Regular meeting / Model accuracy improvement / Model range expansion |

Escort service |

Support service

We would like to introduce our technical support service for Plant Simulation.

* Support services are provided only to customers who have purchased a license from us.

model development

This is a service for developing a Plant Simulation model at our company. We will create a model that matches the factory, process and purpose of each customer in as little as one month.

Flow of model development

Quotation

Escort service (paid technical support)

This is a paid service that provides technical support after installing Plant Simulation.

You can operate the plant simulation smoothly because you can ask questions directly when you are in trouble, and give advice on how to proceed with model creation and projects.

Contents of the escort service

Holding regular monthly meetings

simulator professionalsWe will propose how to use it and how to proceed with the project.

Technical Q&A

on Modeling for Plant SimulationWe will answer your questions.

price

license price

Standard

¥2,500,000 /year (excluding tax)

- ‣There is an upper limit on the number of objects that can be placed (up to 4000 per model)

- ‣Modeling using methods (programming) is possible

professional

¥5,300,000 /year (excluding tax)

- ‣ No upper limit on the number of objects that can be placed

- ‣Modeling using methods (programming) is possible

- ‣Automatic optimization function* using genetic algorithm (GA) is available

・Please note that the above prices are subject to change without notice.

service price

model development

¥1,500,000~ (excluding tax)

This is a service for developing a Plant Simulation model at our company.

We will create a model that matches the factory, process and purpose of each customer in as little as one month.

Escort service

¥1,200,000~ /year (excluding tax)

This service provides technical support after installing Plant Simulation.

- ‣ Regular monthly meetings

- ‣Handling technical Q&A

Inquiry

Toward the realization of the digital twin

A digital twin is a mechanism that reproduces real research laboratories and production facilities in a digital space and links them like twins.

Plant Simulation is just one of the tools that enable the realization of a digital twin of a factory.

There are various merits by realizing a digital twin and having a factory in the virtual space.

A digital twin that creates "three movements" that accelerate Digital Manufacturing. Let me show you its true power.

Click here for more information

digital twin

Digital twin introductory video collection

Let's start with the digitalization of the production process! Introducing everything from the basics of digital twins to how to use them in each industry.

*Application is required for viewing.

white paper

Achieving the Ideal Factory! Eliminate waste in the production process with a “digital twin”

An easy-to-understand explanation of the value of digital twins and how to proceed with their introduction along with case studies.

*Application is required to download.

Plant Simulation Textbook Vol.2, Vol.3

This is a hands-on video where you can learn how to use Plant Simulation and how to create processes.

Plant Simulation Textbook Vol.2

Let's use Conveyor and Assembly!

Plant Simulation Textbook Vol.3

Let's assign people!

\Vol.4 onwards from the YouTube playlist/