製造ライン不良原因分析、歩留まり改善

When using AI to analyze the causes of manufacturing line defects, feeding process data directly into an algorithm will not generate a normal/abnormal judgment model. In order to solve problems with AI, a series of data preprocessing is required, such as combining data and converting it into features.

Pre-processing of such data is often performed manually using Excel, etc. during analysis, making it difficult to implement real-time operations. Macnica will solve such problems.

Do you have any problems?

A NG product was produced, but I do not know which process was the cause

I want to improve yield by discovering important process data related to quality.

Macnica 's strengths

Engineers grasp the current status of the process

Engineers who have experience working on the factory floor understand the current state of the process and dig deep into the issues.

Investigating the Cause of Defects with Big Data Analysis

A data scientist with advanced statistical knowledge investigates the cause of defects using big data analysis

Proposal of new sensor

Based on our sensing technology know-how, we propose additional data and new sensors necessary for process control.

real time processing

We provide solutions for realizing real-time processing and molding of data required for actual operation.

System introduction flow for yield improvement

FLOW 01Understanding customer sites and manufacturing processes

First, we determine if the data we are capturing at your site and manufacturing process is available. Acquire and visualize various types of data from manufacturing and inspection processes.

≪ Manufacturing process data ≫

There are several types to dozens of types of data such as control information and facility operation data for each manufacturing process.

| control information | Operating speed, number of revolutions, set temperature, set pressure, set voltage... |

|---|---|

| Operation data | Manufacturing time, speed, number of revolutions, temperature, pressure, current value, voltage value, vibration... |

≪ Inspection process data ≫

In the inspection process, inspection result information for each lot is accumulated.

your existing data

In order to determine the availability of

Visualize your data

FLOW 02Defect cause analysis

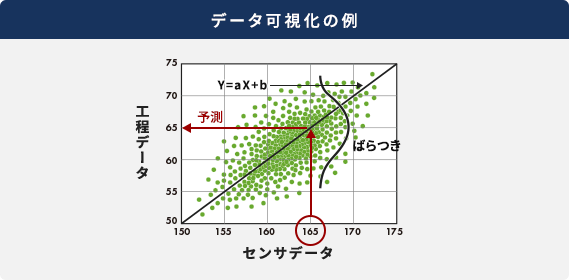

We conduct data analysis using statistical mathematical models and AI to investigate the cause of defects from the acquired data.

If necessary

data acquisition and sensing

We will support you

FLOW 03 Algorithm development for analyzed models

There are various models that can be applied depending on the customer's data and issues.

We provide optimal algorithms by utilizing Macnica 's various analysis technologies.

System construction for FLOW 04 operation

Steps that data scientists used to manually extract features and shape various data must also be automated during operation. At Macnica, we provide software that processes input data in real time, such as feature value conversion of raw process data before data is input into the algorithm, data shaping, etc., and supports implementation into processes.