Okamoto Machine Tool Works,Ltd.

Developed a high value-added grinding machine that can easily achieve high-precision machining.

Okamoto Machine Tool Manufacturing Co., Ltd. has been in business for 90 years and is a machine tool manufacturer with the No. 1 market share in Japan for surface grinders. Grinding using a grinder is a field that requires a craftsman, but as more and more skilled workers who use grinders retire, there are more and more opportunities for workers with fewer years of experience to be in charge of processing.

Therefore, Okamoto Machine Tool Works, in collaboration with Macnica and Core Concept Technology, has begun a project aimed at creating machine tools that are easier to use and that anyone can achieve accuracy. Here, we spoke to members of the project.

USER PROFILE

■Corporate Information: Okamoto Machine Tool Works,Ltd.

■ Business content:

Okamoto Machine Tool Works,Ltd., Ltd., as a "comprehensive abrasive processing machine manufacturer," supports the manufacturing of high-quality, high-precision products in the fields of machine tools and semiconductor-related equipment, and contributes to next-generation "manufacturing." Under the corporate motto of "Proper technology", we are constantly challenging ourselves to become a world-class machine tool manufacturer that can create beyond what our customers want.

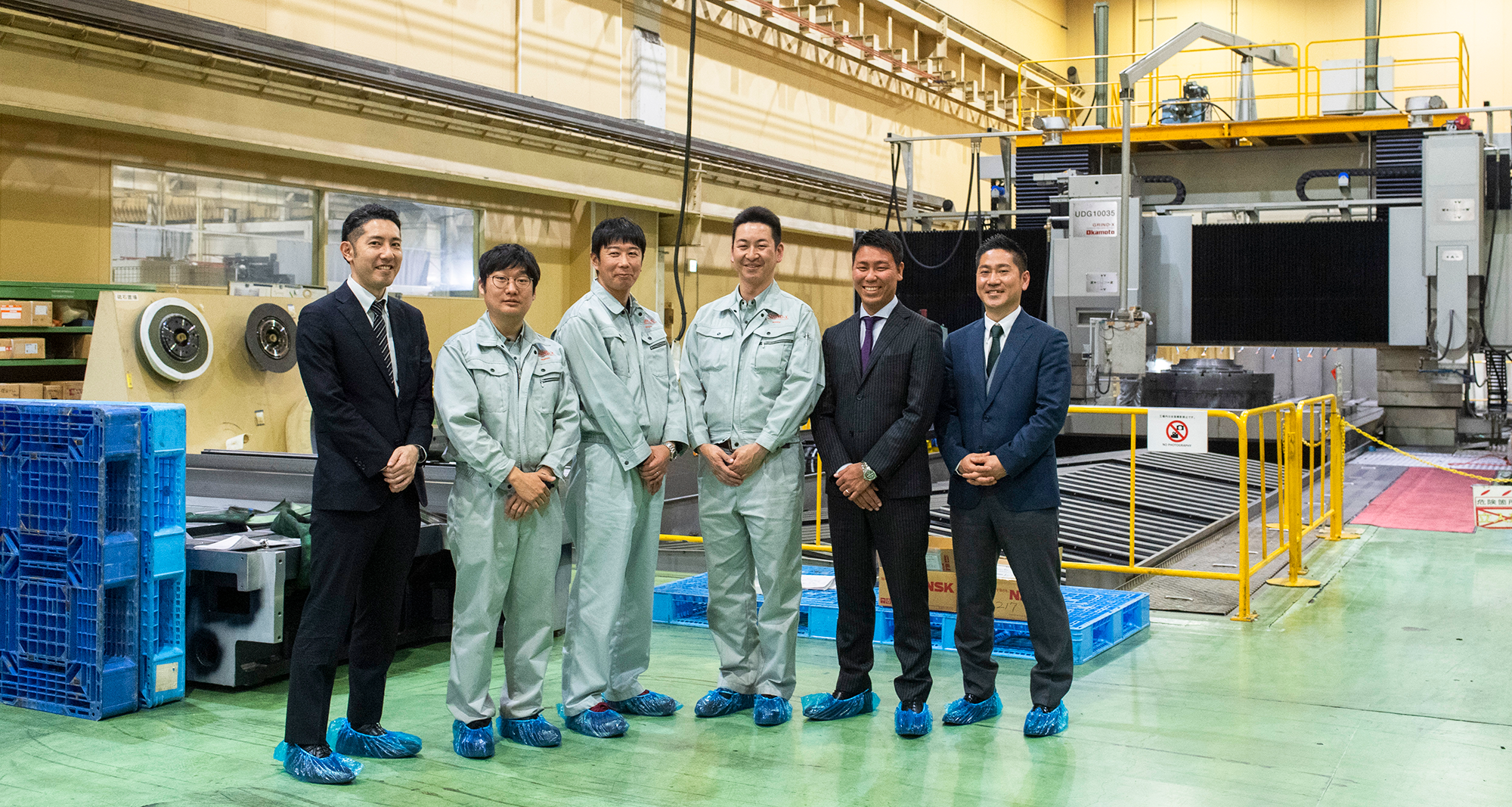

From left

Mr. Ryo Kayada, Assistant Manager, Sensing Section, Consulting Technology Department, Technology Management Division, Innovation Strategy Business Headquarters, Macnica

Mr. Kazuhiro Nishigami, Team Manager, Marketing Team, Product Planning Department, Technology Development Division, Okamoto Machine Tool Works,Ltd.

Okamoto Machine Tool Works,Ltd. Mr. Yutaka Yoshida, Manager, Product Development Section, Development Department, Technology Development Division

Okamoto Machine Tool Works,Ltd. Mr. Kuninobu Matsuoka, R&D Manager, Product Development Section, Development Department, Technology Development Division, Annaka Plant

Macnica Kenji Matsumoto, Section 2, Professional Service Department 2, Industrial Solution Division

Mr. Kenichiro Wakisaka, Sales Manager, IoT/AI Products, President's Office, Core Concept Technology, Inc.

A grinder that anyone can use for high-precision processing

― Could you tell us what made you start this initiative?

Mr. Yoshida:

Grinding is a field that requires craftsmen. However, recently, skilled craftsmen are gradually disappearing.

We come.

That's why we started this project, aiming to create a machine that is easier to use and that anyone can use to produce accurate results.

The development concept is to enable both craftsmen and young children to process with the same precision.

When our customers use our machines, they adjust various elements of peripheral equipment such as grinding wheels and grinding fluid.

We believe that our ultimate goal is to share this information, quantify grinding know-how, and utilize AI.

When we thought about introducing AI to achieve our goals, we didn't have an analysis team.

Although there are units capable of acquiring data, there is no group that can effectively analyze that data.

Therefore, in collaboration with Macnica and Core Concept Technology, which have such analysis know-how, we began development with the idea of incorporating AI technology into our grinding machines.

- Could you tell us why you chose Macnica and Core Concept Technology?

Mr. Yoshida:

The main reason is that there are not many companies that handle both sensing technology and analysis.

In terms of industry trends, IoT has taken off and activities such as acquiring and utilizing vibration data have taken the lead.

Of course, we also received proposals from other IT vendors.

However, Macnica was the most advanced in terms of not only acquiring data but also providing a comprehensive view of various aspects.

Also, when it came to AI proposals, other companies often said things like, ``They have something like this,'' or how about this package, but in Macnica 's case, they first listened to our opinions, and based on that, they made concrete plans. It was very nice to be able to transform it into something.

I think Macnica 's strength is that they understand our current issues, visit the actual site, understand what we want to do, and then make suggestions.

Another reason I chose this company was because they enthusiastically came to do sales.

I felt strongly that people were interested in what we wanted to do.

Matsumoto:

Macnica has been touring manufacturing industry sites across the country to promote smart factories, and has a deep understanding of the manufacturing industry.

This is the first time we have dealt with the technology of grinding machine abrasive grains, but we have continued to carry out steady work such as visiting actual sites, collecting opinions from end users, and researching papers, which has led to proposals for commercialization. Masu.

Quantify the work in the craftsman's mind

― Could you tell us about the outline of this initiative?

Mr. Yoshida:

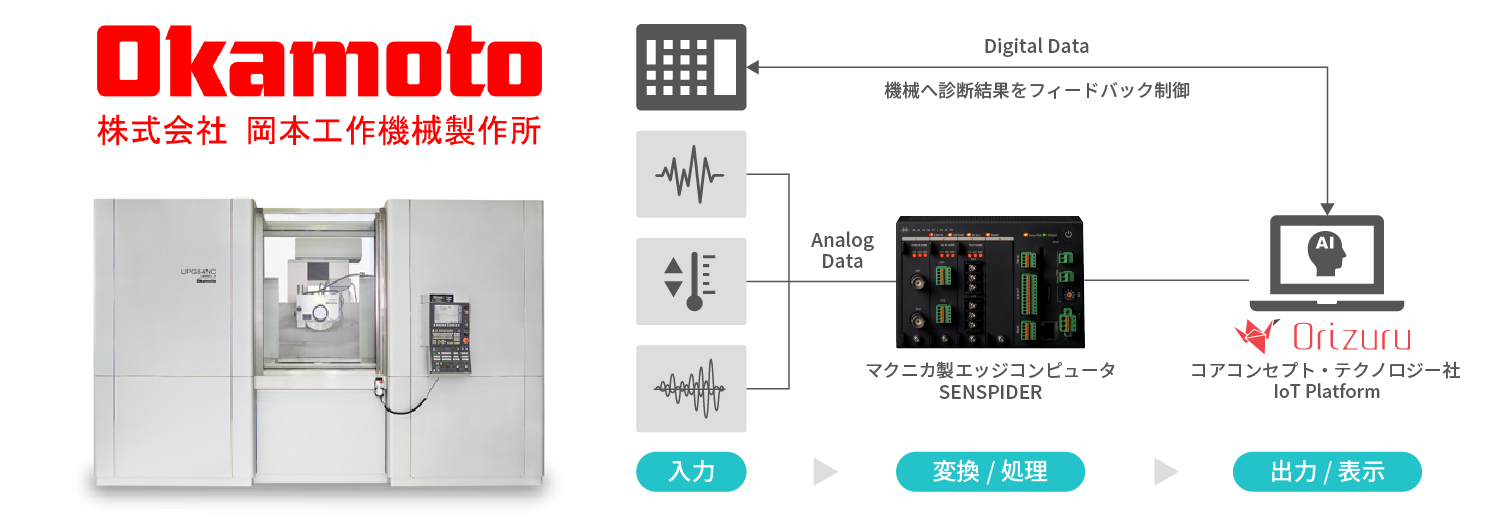

In order to develop a grinding machine that allows anyone to perform high-precision machining, regardless of the number of years of experience, Okamoto Machine Tool Manufacturing Co., Ltd. utilized sensing technology and AI technology to analyze current grinding machines. We have begun working with Macnica and Core Concept Technology to visualize issues.

Mr. Matsuoka:

First, in order to capture the phenomenon that is the theme of this project, we first confirmed the structure of the machine, selected the necessary sensors, developed software to efficiently collect data, and developed individual treatments. We made the equipment and installed the sensor.

This time, sensors were installed at 30 locations.

The reason we started with 30 locations was because we were starting from a state where we didn't know where and how much influence they were having, so we thought we could get by with the maximum number we could think of.

Macnica was very helpful in assisting us with the complex aspects of the manufacturing industry, such as supporting sensor installation work on site and making detailed adjustments to work schedules.

Matsumoto:

The machine maker is usually processing.

As a result, the amount of time that the machines can be used freely is limited, so we did unrefined things like attaching sensors to the equipment together on weekends. It's a good memory. (smile)

― Could you tell us about the merits that can be obtained by using AI technology?

Mr. Nishigami:

First of all, I think the value of this initiative is that our employees can get to know our machines better than ever before.

In the first place, machines operate with these three elements: hardware, software, and people.

If we can incorporate sensing and AI technology into this “human” part and control it well, we can see new products.

Quantify the work done in the mind of the craftsman.

I think it's the same level as a car autonomous driving.

Mr. Yoshida:

We are currently at the stage of teaching AI how things have changed, with the aim of realizing AI that can compensate for how a machine moves in real time.

Kayada:

First of all, it is important to thoroughly understand the acquired data and utilize simulations and other methods to understand the physical phenomena.

Based on this information, we are utilizing the knowledge of Macnica and Core Concept Technology to build an AI model.

Mr. Wakisaka:

Core Concept Technology works closely with Macnica on a regular basis.

As a partner company, when Macnica makes proposals to customers, we complement each other's technical knowledge and help provide optimal proposals and technical support.

system configuration diagram

Keeping in mind the concept of a machine that nurtures people

― Could you tell us about the status of the project?

Mr. Yoshida:

The project is moving forward with the initial goal of using sensing to learn about the movements of machines that were previously invisible.

Ultimately, our ultimate goal is for our machines to be accurate no matter how they are used.

However, at a seminar sponsored by Macnica, there was a university professor who said the keyword ``nurturing people'', which I think is going against the times.

However, this is actually true, and even if our machines can be used by anyone to a certain extent, I think we still need to remember that it's all about people.

I would like to deepen my efforts while also considering the concept of ``a machine that develops people.''

We will continue to work with Macnica and Core Concept Technology to decide what kind of business we will develop and what products we will create for the customers who use our machines. I think we need to think about this.

In each episode, it feels like everyone is looking to the future and sharing their opinions, so I think we're heading in the right direction.

How it will be done in the future

― Could you tell us about your future efforts?

Mr. Yoshida:

The next challenge is to deal with operating modes.

When a product hits the market, it will be used in many different ways and will operate in various modes of operation.

In such a case, I think it will be very important whether the AI model created can make correct judgments.

My first immediate goals are to improve the accuracy of the model and systemize the control, and then I hope to commercialize it.

-Could you tell us your requests and expectations for Macnica?

Mr. Yoshida:

We hope that Macnica and Core Concept Technology will continue to come up with technologies that we do not have.

We must cooperate with this, and we would like to make efforts to understand it.

We tend to have fixed concepts about grinding machines, so we have high hopes for Macnica and Core Concept Technology, who have strengths that we don't have and new ideas that we don't have.

*Information and company names in the text are current at the time of the interview.