この記事を読むのにかかる時間

5分

はじめに

こんにちは!

「工作機械へ新たな価値を」をスローガンに、工作機械メーカー様へAIやIoTを活用した課題解決を伴走型スタイルでご提案させていただく専任部隊、“チームメタルプロセッシング”の創立者兼書記のKODAIでございます。

さて、「EMO 2019で見た“ええもん”お届け~ハノーバー秋の工作機械祭り~」第2回目をお届けいたします。

全体的な技術トレンドってどうなっているの?

さて早速ですが、EMO 2019のAI IoTに主眼を置いた技術トレンドは以下のとおりと感じました。

- IoT:umatiの活用 = Industry 4.0への対応

- AI:本質的な活用手段へのシフト。キーワードは自動化・最適化

それぞれについてお伝えしていきたいと思います。

IoTトレンド:umati 対応

EMO 2019は完全に“ドイツ秋のumati 祭り”といってもよい状態でした。

そもそもumati ってなんだ?って方。

ユマーティと読みます。

一瞬お米の銘柄か秋田の美人か、と思ってしまいましたがそんなことはなく、Industry4.0具現化の手段ともいえるEMO 2019最重要テックトレンドの一つということが判明しました。

umati=Universal Machine Tool Interface の略で、ドイツ工作機械工業会(VDW)が策定し、世界標準化に向けて推進する工作機械向けの情報モデルのことです。情報モデルについては第3回目にてエンジニアより詳しくご紹介いたします。

さて、umati は前回のEMO 2017で大々的に発表され、今回のEMO 2019では、実に10ヵ国70メーカー110機がumati でつながり、実稼働情報をリアルタイムに収集・見える化する展示がありました。

umati 特設ブース

展示ブースでは稼働する各国の工作機械の稼働データが一括表示されておりました

© Deutsche Messe

会場のいたるところにumati 対応の工作機械がありました

© Deutsche Messe

umati は機械の中のさまざまなデータを通信することができ、活用への期待が膨らみますが、今回の展示では一部の情報に留められていたこと(機械自体の稼働有無と主軸の回転速度に限定)、また、実際につながった先の価値提供にまで踏み込んだメッセージ訴求はこれからといった印象でした。

ただ、2017年のEMOでのumati コンセプト発表からわずか2年あまりで今回、数多くのメーカーを巻き込んだ動的なデモ展示へ進展させており、その開発スピードは目を見張るほどです。2年後のEMO 2021ではより具体的な現場活用まで踏み込んだ内容となっていることが期待されます。

なお、EMO 2021はイタリア開催です。

ミラーノでユマーティ、なんておしゃれな響きなんでしょう。

ここで、各国の動向を見てみます。

日本で異なる工作機械同士をつなぐIoTプラットフォームといえばファナックのFIELD System です。

アメリカの工作機械の通信プロトコルといえばMT Connect が一般的です。

実際、昨年のJIMTOF 2018では各工作機械のデータをFIELD System 上でつなぐ展示がありました。

umati はOPC UAベースの通信プロトコルです。

FIELD System はOPC UAにも対応しておりますし、MT Connect とOPC UAも連携を推進しており、MT Connect の標準データモデルで通信プロトコルとしてHTTPの代わりにOPC UAを採用する取り組みなどを進めています。

さまざまな通信プロトコル、IoTプラットフォームが存在していますが、今後これらの規格は相互連携を進め、工場全体が一つにつながっていくようになると思います。

AIトレンド:本質的な活用手段へのシフト キーワードは自動化・最適化

AI活用を謳った工作機械の展示はごくわずかで、日本の大手メーカー様のブースで見受けられる程度でした。

実際AIは工作機械では流行らないのか?

答えはNo、そんなことはないと思います。

むしろ着実に進んでいると感じました。

いわばAIバズワード時代の終焉です。

AIを使うこと自体が先進性を示すための目的と化していたかつてのトレンドは落ち着きを見せ、本質的な価値創出のための手段に立ち返っている印象を受けました。

では、どのような活用方向性が見て取れたか?実際の展示例を絡めてご紹介します。

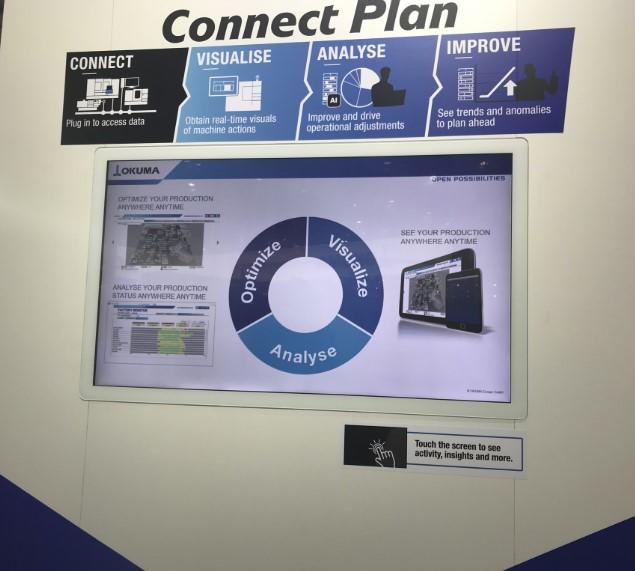

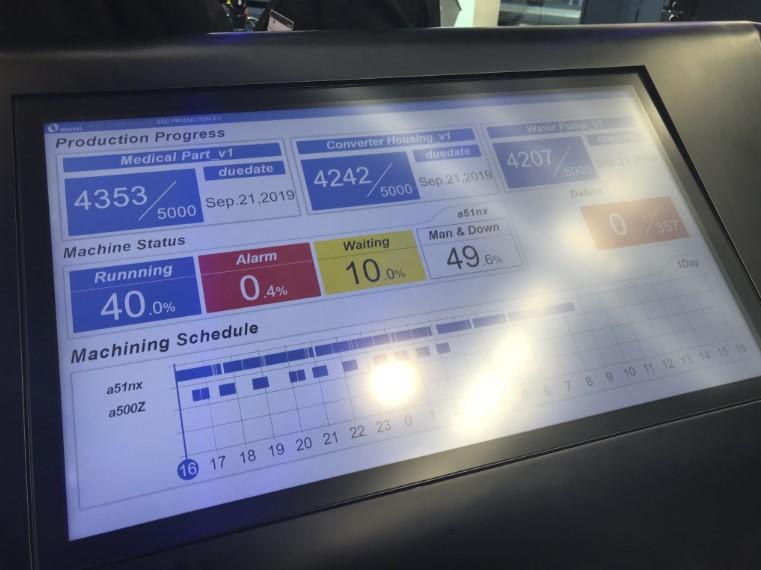

■オークマ様 Connect Plan “工程エラーの原因究明”

工程管理最適化へのAI活用です。

単にエラーが起きているという情報だけではなく、具体的にどのような原因によりエラーが生じているのか、過去の学習結果をルールベースで照らし合わせ、最も類似するエラー原因を提示してくれる、といった内容です。

エラーが起きたら都度現場に作業員が行って詳細確認をしなくともリモートで対策を行うことが可能となります。

稼働監視の次のステップとして、工程のデータを収集したら次にはこのようなテーマが増えていきそうですね。

■ヤマザキマザック様 MAZATROL SmoothAi “加工パラメーターの最適設定自動化”

3D図面を入力すると、自動的に最適な加工パラメーターをAIが生成します。

CNCにベースとなるアルゴリズムを保有しており、稼働後もユーザーの評価にあわせてアルゴリズムを再学習、個別の環境にあわせてシステムの精度を上げていくことが可能。

まさに職人の技伝承ですね。

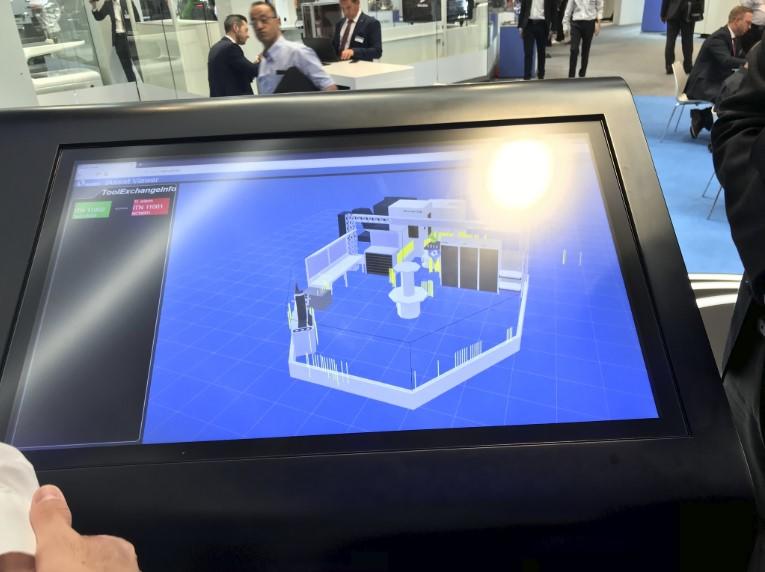

■牧野フライス様 工程プランニング自動化/最適

入力された加工オーダーに対し、最適な工程プランをAIが生成してくれるというもの。

日々のオーダーや差し込みにあわせた工程プラン立てと修正には、かなり労力を要しますが、この作業を自動化&最適化できる仕組み。

なお、別に展示されていたAGVとロボットによる工具自動搬送システムとも連動し、より省人化を推し進めることが可能。

ここまで自動化できるなんてすごいですね!

AGVとロボットの組み合わせによる工具自動搬送システム

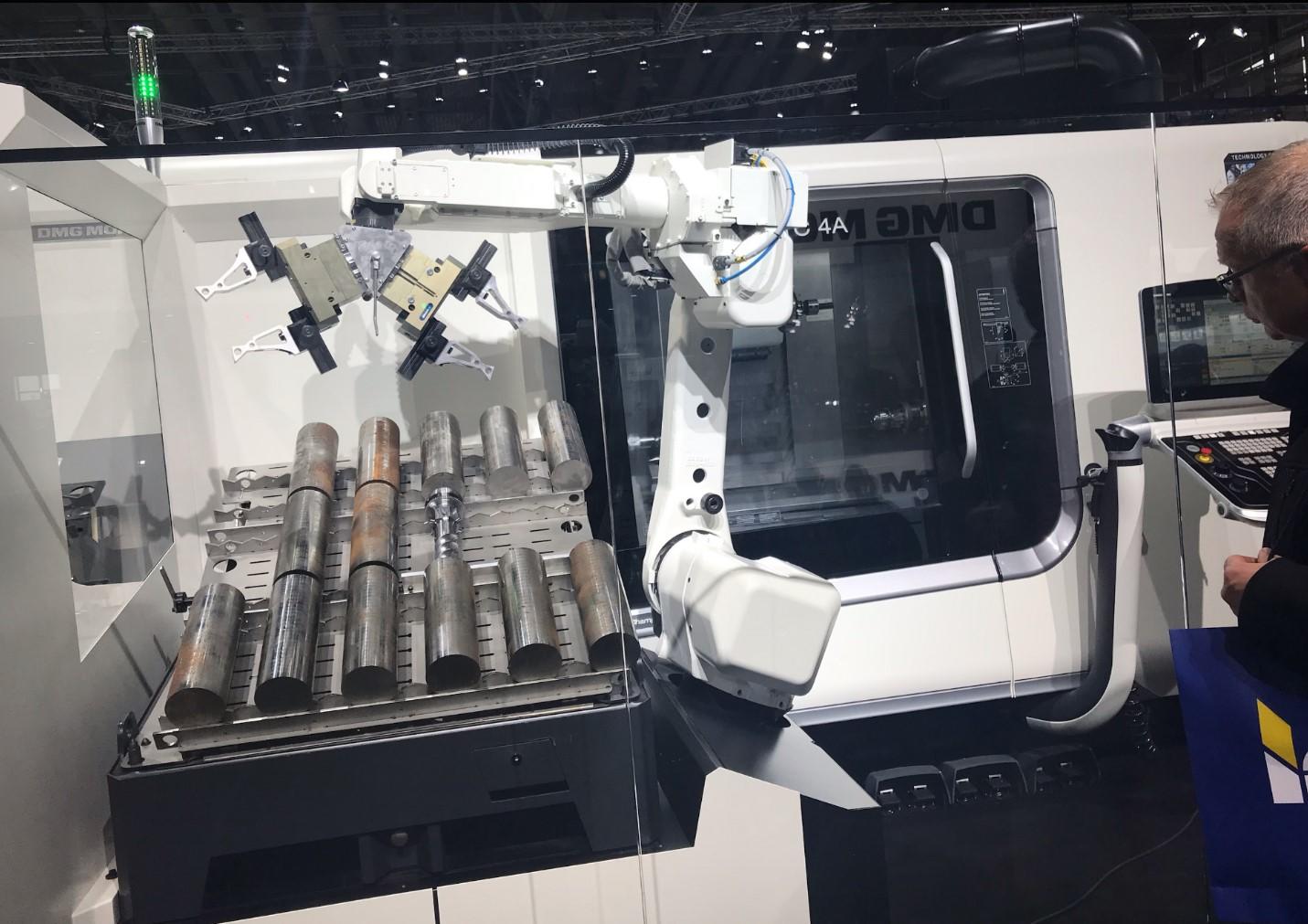

■DMG森精機様 “DMG MORI CONNECTIVITY IN STANDARD”

具体的なAI活用のテーマ展示こそありませんでしたが、むしろ強いメッセージを感じたのがDMG森精機様です。

MQTT、OPC UA、umati、MTConnect、FIELD SYSTEM、MindSphere…他社含めすべてつながる環境構築を堂々宣言しており、まさに世界のDMG森精機様ならではのスケールでした。

JIMTOF 2018でも熱変位補正機能などAIを活用したテーマを数々展示し、常に最先端を走るDMGさんだからこそ、あえて具体的な展示は伏せ、そもそもAI活用のためにはオープンなデータ収集基盤の構築が必須というシンプルかつ本質的なコンセプトをこのEMO 2019に持ってきたのだと感じました。

以上、AI活用の展示事例でした。

やはり、全体的な業界トレンドである自動化の流れの中で、AIは必須技術だと改めて実感しました。

[自動化が進む⇒現場の省人化⇒人の判断を代替えする知能が必要=AI活用]の図式が見て取れ、自動化を展示していた会社はAI関連の展示も多かった印象です。

また、数年前までAI活用テーマといえば機器単体の予知保全が代表的でしたが、用途や対象がだいぶ充実してきたように感じます。

用途は故障やメンテナンスへの対策から日々の業務プロセスに紐づく活用テーマが増え、対象は機器単体から工程全体にシフトしている様子がうかがえます。

予知保全も実際に本格導入が進むのは工程の自動化がより進んだタイミングということになりそうです。

こうなるとオープンに工程データを収集するプラットフォームや、ユーザー使用環境ごとにAIを個別最適化可能な仕組みづくりが必要となります。

ここはマクニカも力を入れたいと考えています。

自動化で忘れてはいけないのはロボットと工作機械の連携です。EMOでも多く展示あり、定番化した感があります。

ヤマザキマザック様

DMG森精機様

ロボットとの連携は定番化しつつありますが、まだまだ技術進歩というか、ユーザー視点に立った新機能が出てくると感じました。

例えば、ヤマザキマザック様の旋盤についているロボットは、ゲージ無しで使用されています。

こちらは、センサーを搭載して人が入ってきたタイミングでアラームがあがり、距離によって完全に止まる・止まるけど自動で再稼働し始める、といった仕組みが取り入れられているようです。

また、ピッキングロボットのティーチングにおいても、まだ現状は職人が工程にあわせて個別に調整しているケースが多くありますが、最近はこのティーチング作業を画像とAIの組合わせで自動化していく動きも見て取れます。

工作機械の進化と一緒に、協調して使われるロボットの自動化に向けた技術革新も進んでいくのではないかと思います。

さて、第2回目は以上となります。

第3回目は“技術担当・モリリが独自の視点でお届けする技術トレンド深堀”をお届けしたいと思います。

どうぞお楽しみに!

※本文中に記載のある情報、および会社名は2019年9月時点のものです。