product

- Why choose Splunk

- Installation record

- price

- Splunk Enterprise Security

- Splunk Phantom (SOAR)

- Splunk ITSI (Next Generation IT Operations)

- Splunk Observability Cloud

- Splunk UBA

- Macnica CSIRT App Basic

- App for Splunk for Financial Institutions

- Splunk Analytics for Hadoop

- About Apps

- Splunk Edge Hub

- What is Splunk

service

- Dashboard/SPL Creation Pack [Implementation/Building Support]

- Version upgrade service [implementation and construction support]

- Smart Security Monitoring App [Original App/Service]

- Splunk × LANSCOPE Original App [Original App/Service]

- Security Monitoring App for Box [Original App/Service]

- Cloud Security Monitoring App [Original App/Service]

- List of services

Specifications/Technical Information

Application for evaluation machine

- FAQ

Splunk

Splunk

Solving Problems with Splunk-IoT/M2M

Enabling maximum use of IoT data

Machine data analysis platform "Splunk"

Attention to big data, which creates new business opportunities from vast and diverse data, is rapidly increasing. IoT data is becoming big data day by day, unstructured data is added to structured data, and the types of data are extremely diverse. In addition, the frequency of data changes is high, and the combination of these conditions makes it difficult to handle with conventional databases such as general-purpose RDBs. Furthermore, due to the structural problem that the user department that utilizes the analysis results and the information system department that builds the database for log collection and analysis are separate, there are many problems in terms of speed and flexibility in communication and information utilization. I would like to ask about a case where a problem with

Are you having trouble with these IoT/M2M issues?

- 種々雑多なログを取得する仕組みづくりやDB化に多くの時間とコストが必要

- Different devices have different log formats, which takes time to collate and integrate

- Log format normalization required for each module or application change

- It's hard to communicate with the IT department many times to create a DB or dashboard where you can see the information you want to see

- Adding new logs to the completed DB and changing the analysis axis cannot be done quickly and flexibly

- With general-purpose RDBs, it is difficult to analyze huge amounts of real-time raw data due to processing capacity issues.

It can be solved by introducing Splunk

Splunk enables you to:

- Real-time search of vast and diverse data

- End users themselves can search, analyze and report

- Integrate data by linking with existing Hadoop and DB

- Easy to deploy and scale, low cost

Splunk, an analytics platform that enables maximum utilization of IoT data

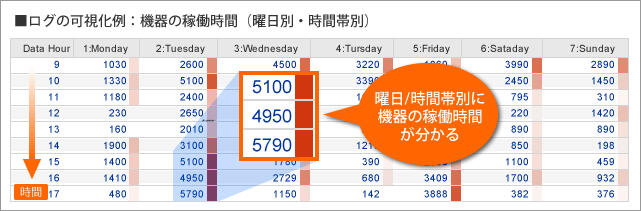

Collect/integrate/visualize all machine logs such as equipment and servers

"Splunk" makes it possible to use such huge and diverse IoT data easily and at low cost. Splunk, a machine data analysis platform, collects and analyzes logs from all machines, including servers, network equipment, business systems, facility equipment, and various sensors installed in products, in real time, regardless of the data source or location. integration. It provides an environment in which even users without specialized knowledge and skills, such as sales, corporate planning, marketing, and call centers, can search, analyze, and visualize logs with simple operations.

Three cases explained! Advantages of IoT data utilization in the manufacturing industry

Introducing IoT data utilization scene using analysis platform

As you probably already know, let's briefly explain the benefits of IoT data utilization in the manufacturing industry. If we can unify and analyze a huge amount of diverse information, such as logs of various equipment at manufacturing sites, the operating status of equipment introduced to customers, and customer feedback received at call centers, etc., from various angles, we can use the results in product development and development. It can be used for quality control, demand forecasting, and traceability after sales. Now let's look at three IoT data utilization cases.

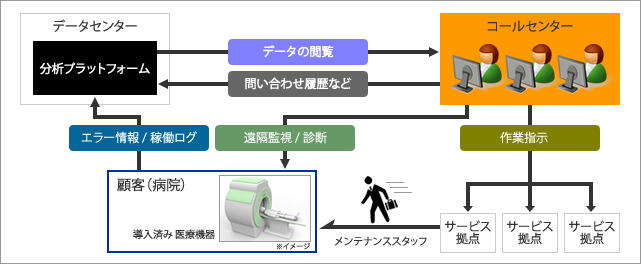

1: Improve customer satisfaction by responding quickly and accurately to medical equipment failures

Medical device manufacturer Company A collects operating data of medical devices installed in hospitals in real time or in batches, combines it with call center inquiry histories, customer feedback, etc., and manages it comprehensively on an analysis platform. there is

When a customer reports that there is a problem with the device, the staff checks the status of the device on the analysis screen. While looking at the dashboard that displays the operating status of the equipment in an easy-to-understand manner, they respond appropriately. In addition, depending on the nature of the problem, we dispatch maintenance staff to the customer's site to quickly solve the problem. Through such meticulous support, we have achieved a significant improvement in customer satisfaction.

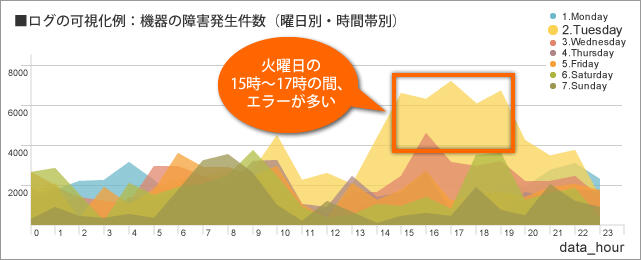

2: Predict various conditions that lead to failures and prevent problems before they occur

Electric equipment manufacturer B collects operation logs of the equipment it sells on a daily basis and analyzes them on an analysis platform. Based on logs of past failure occurrences, various conditions of failure occurrence and cause identification are performed. Utilization of such IoT data makes it possible to improve problems that lead to failures and to detect and avoid failures before they occur.

3: High-precision prediction of demand such as expansion and replacement timing from operation logs

Transportation equipment manufacturer C collects operation logs of the equipment it sells in real time. We always know when and for how long which equipment is in operation at which sales destination. Using this data, Company C predicts the deterioration of equipment over time and implements appropriate maintenance measures. In addition, if necessary, we propose equipment expansion or replacement, and acquire business opportunities that anticipate customer needs.

movie

【Splunk社動画】Splunkとモノのインターネット

Learn how Splunk can help the Internet of Things.

Weekdays: 9:00-17:00

Inquiry/Document request

In charge of Macnica Splunk Co., Ltd.

- TEL:045-476-2010

- E-mail:splunk-sales@macnica.co.jp

Weekdays: 9:00-17:00