The use of IT is now essential for companies to survive the harsh competition for survival.

The manufacturing industry, which has supported and led the development of Japan, is no exception, and the promotion of DX is an urgent task.

However, in reality, there are many obstacles such as "delay in data utilization", "system black Box", and "lack of digital human resources".

In order to break down these barriers, electronics manufacturer M introduced Macnica 's ``Digital Synergy Factory'' service.

Through this service, which brings together Macnica 's "knowledge," "services," and "technology," it will be possible to quickly realize a smart factory by promoting step-by-step digitalization, and the company expects to achieve a growth rate of over 10% in the medium to long term. We expect productivity to improve.

In this article, we will introduce the DX promotion case of electronics manufacturer M.

Background of DX promotion

At M Company, a leading electronics manufacturer in Japan, management quickly recognized the need for DX and incorporated it into their medium-term management plan.

However, the project continues to be slow and stagnant, and many people say, "I don't know what to start with," "I can't make an investment decision because I can't see any concrete effects," and "I don't have enough human resources." It was a situation where there was too much content to be done.

“Whether we are trying to improve the efficiency of existing businesses or improve business value, it is necessary to change business processes, collaborate between departments, and coordinate systems. It was necessary to draw a solid grand design for the DX platform.In addition, while the Company is accelerating the shift to digital due to the impact of the corona crisis, the current unstable economic environment has made it difficult to approve the plan. There was a growing demand for speed, and against this background, the burden on project leaders and members increased dramatically, making it difficult for upper management to judge the appropriateness of policies and whether progress was good or bad." ( Company M)

Decided to introduce "Digital Synergy Factory"

Company M decided that it would be difficult to promote DX on its own.

After considering several measures, we introduced Macnica 's smart factory support service ``Digital Synergy Factory.''

“The impetus for the introduction was participation in a webinar, where I learned about workarounds for problems that manufacturing companies tend to fall into when promoting DX. ) The fact that it consistently covers the area is also attractive, and I thought that this would be good.” (Company M)

First, Company M worked to create a system to facilitate smooth communication with Macnica 's support.

In promoting DX, collaboration between departments and systems is required, and a project team needs to stand between each department and management.

In order to achieve this, it was necessary to strengthen mutual communication and bring together "management," "DX team," and "related departments."

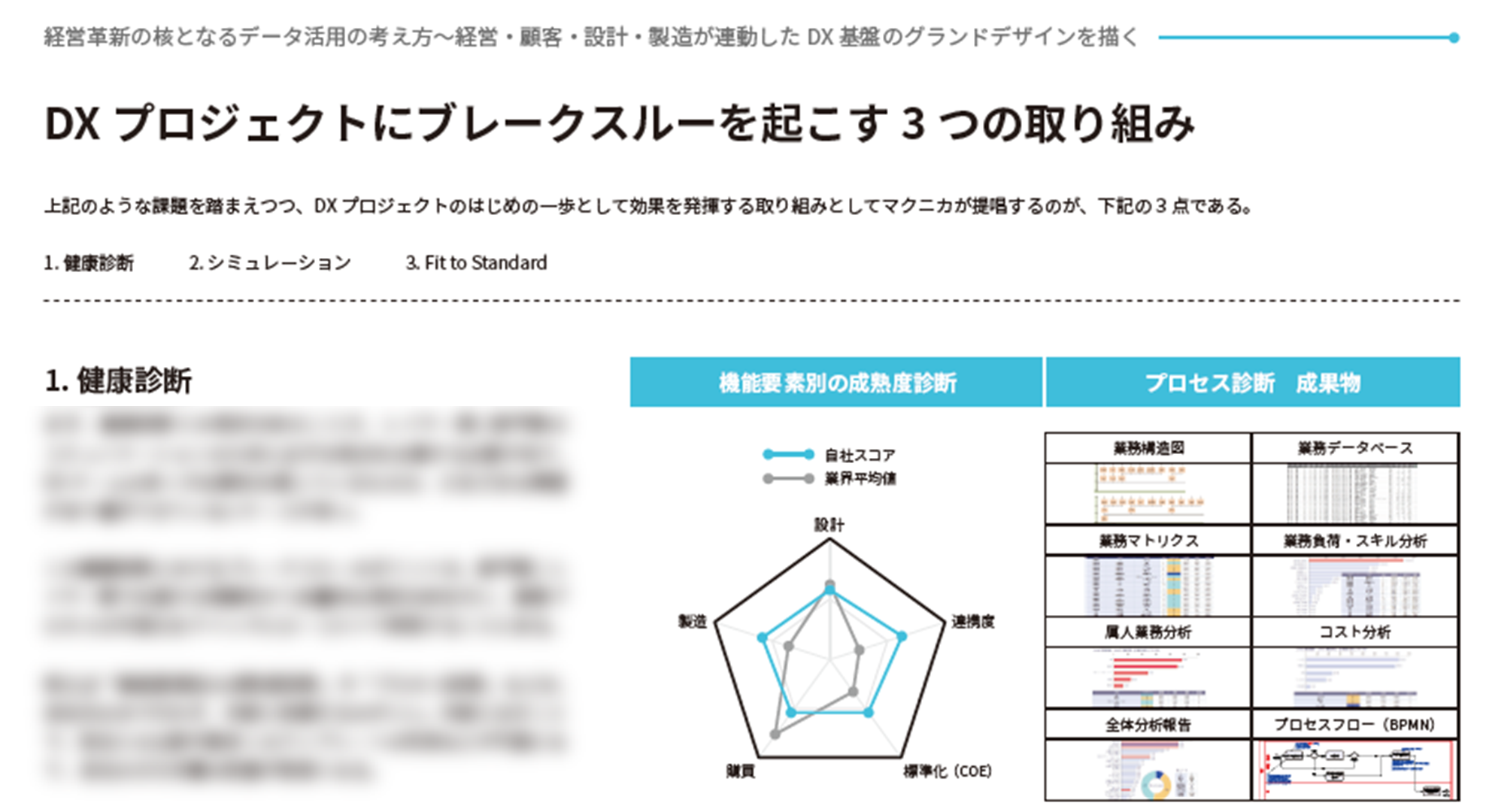

Next, the following four points were raised as points that cannot be overlooked when proceeding with the project.

|

❶ |

Medical checkup |

|

❷ |

simulation |

|

❸ |

Fit to standard |

|

➍ |

Security |

Medical checkup

A health checkup is an analysis of the current situation, and confirms the position of the company from a third-party perspective.

This is also necessary when agreeing on a starting point for inter-departmental and inter-layer communication. Visualization must be achieved quickly and at low cost.

simulation

Simulation is effective in avoiding project pending due to speculation.

There is no better communication than sharing experiences, so we use simulations to reproduce processes and factories quickly, cheaply, and with 70-80% accuracy without making too many details.

It is important to grasp general trends, set issues, improve accuracy for practical use, and model for deployment.

"Using Macnica 's service (digital factory introduction support service), which builds models of actual processes and factories in digital space, we were able to create a factory demo scenario and image scenario in about two weeks." (Company M)

Fit to standard

A common problem with digital infrastructure in the manufacturing industry is that it takes a huge amount of man-hours and time to define requirements, and changes cannot be imagined.

The solution is the "Fit to Standard approach."

Compared to Fit & Gap, the user load and required skills are higher, but it is possible to improve "development cost", "introduction period" and "system maintainability".

In addition, it has the advantage of being able to respond quickly to the latest vulnerabilities in security measures, and it is easy to respond globally.

Security

With the promotion of DX, system linkage will advance, and security risks will increase if things that were previously unconnected are connected.

At that stage, it is necessary to consider security measures covering the IT and OT areas.

中長期的に10%以上の生産性改善を見込む

Currently, Company M's project is progressing from the DX concept study to the grand design of the DX platform that links management, customers, design, and manufacturing.

In some cases, we are also working on general design for each area, and we are also conducting experience and verification with an MES (Manufacturing Execution System) that actually works.

"By utilizing Macnica 's services, we were able to break down obstacles and move the project forward swiftly. In particular, they cover both the IT and OT fields consistently, which was a big help in allowing us to draw up a grand design from the perspective of overall optimization rather than partial optimization. In addition, they have many staff members well versed in IT and OT, and the resolution is high, so they can cover things close to the site, such as system delivery. I felt that this is a service that consulting companies and the like cannot provide." (Company M)

Going forward, Company M expects to improve productivity by more than 10% in the medium to long term through the DX project.

To those in charge who are worried about promoting DX

At Macnica, we support companies that are serious about promoting DX based on our experience of supporting approximately 300 digitalization/AI implementation projects in the manufacturing industry.

If you have troubles such as "I don't know where to start," "I can't see the specific effects and can't make an investment decision," or "I don't have enough human resources," please feel free to contact us.

Information on the white paper that further digs into the points of this article

We have prepared a white paper where you can learn more about the "health checkup", "simulation", and "Fit to Standard" mentioned in this article, and the three points that lead to the success of DX promotion.

There are hints for those who want to learn more about DX promotion and seriously want to succeed in DX, so please take this opportunity to see it.

*Registration required for viewing/downloading