Introduction

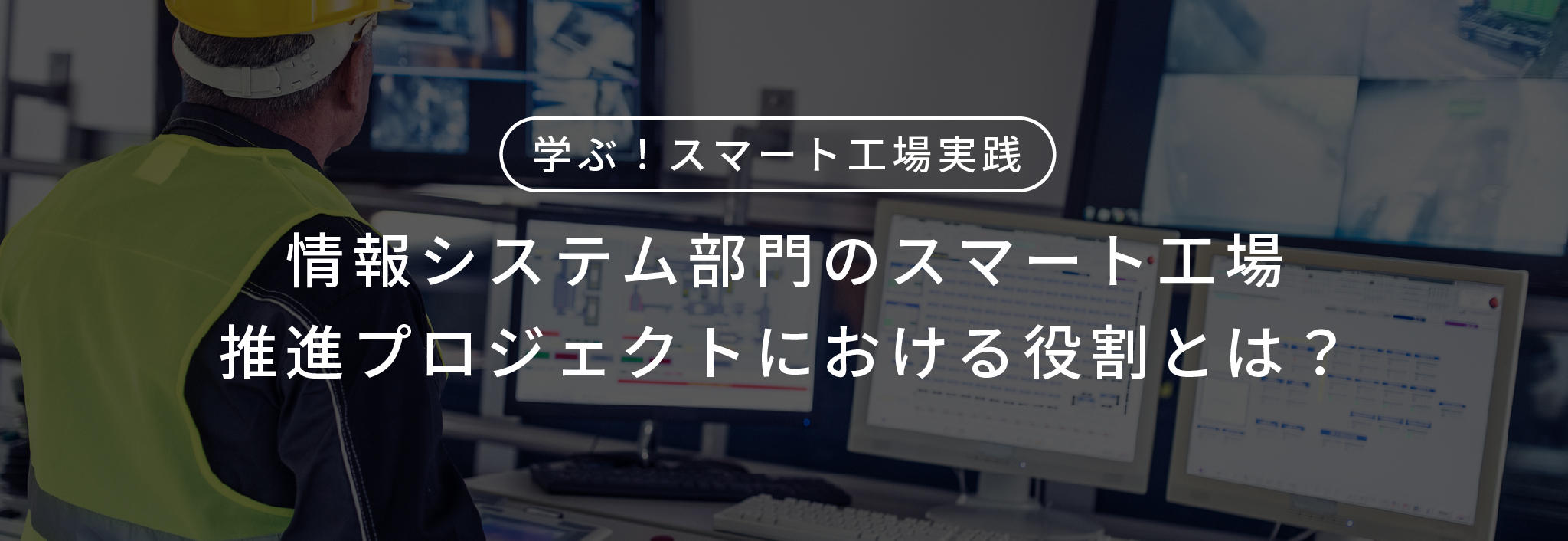

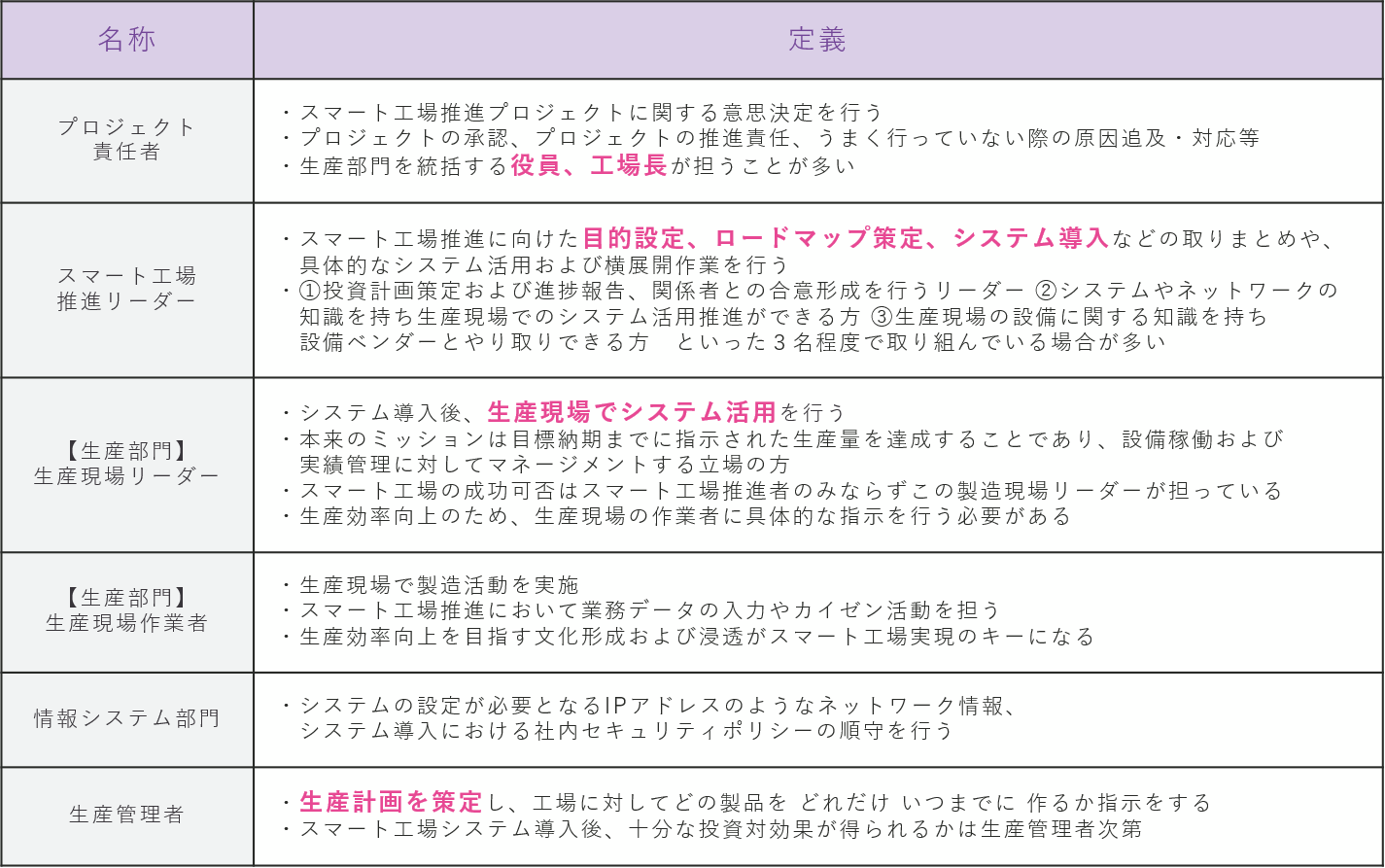

The smart factory promotion project is a highly complex project in which people in various positions are involved.

In this column, how does the information system department view the digitization of the production site as the smart factory promotion project progresses? What should be defined as the role of the information systems department? I would like to discuss with you about

[Information on recommended white papers]

For the smooth promotion of DX in the manufacturing industry, it is also important to specify "target indicators."

This white paper introduces the points that the organization should be aware of in order to work together toward the goal of "continuing to be a profitable factory."

This article discusses how to successfully implement a highly complex smart factory promotion project.

・Information system department: How should I be involved in the project?

・Smart factory promotion leader: How should the information system department be involved in the project?

I will explain the above two points.

How does the digitalization of the production site look from the information system department?

1. It is difficult to grasp the specific measures

Even if many people in the information systems department worked in the manufacturing industry, isn't there only a small number of people who have actually been engaged in production activities?

Of course, people in the information system department are professionals in system development, such as building databases, automating data aggregation, and building data utilization dashboards. As a result, they do not have the opportunity to actually engage in production activities or touch production equipment, so they cannot imagine what kind of data can be collected in the first place or how to use the data specifically. I often hear that.

2. It would be a problem if you were asked to create value through data analysis at the production site! ?

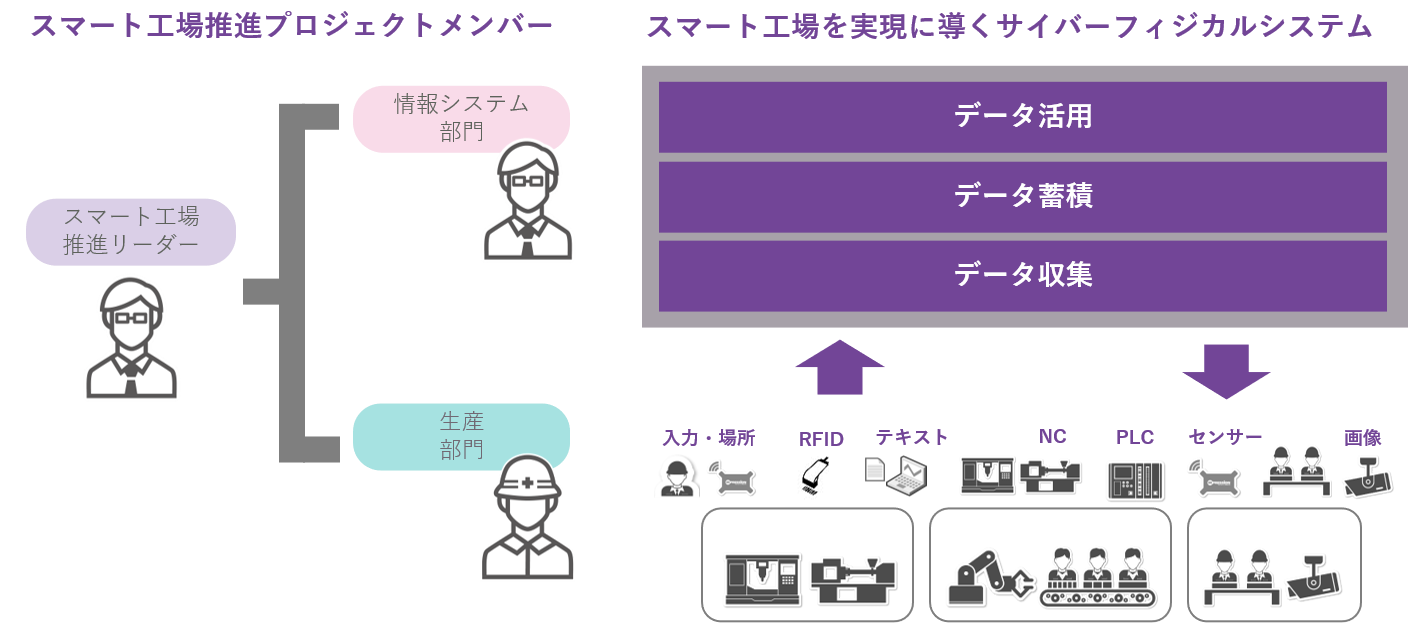

Recently, the words IoT, AI, DX, and digital transformation have spread widely, and in the company management (factory management) of the manufacturing industry, the improvement of corporate value through the use of data has become widely touted. For this reason, there are companies that are asking their information system departments to create added value by utilizing data that can be accumulated in-house due to expectations for system utilization and data utilization.

From the perspective of digital utilization at the production site, it seems that the information system department often asks the production department because they do not know what to do. However, if the production department does not have a specific idea of what they want to do, they will want to connect to a network, accumulate data, and visualize it.

As a result, the reality is that the information system department feels that value creation through data analysis required by management is an "impossible subject."

3. I don't have a good image of the digitization of production sites! ?

Even so, some companies are promoting digitization with the information system department taking the lead in close proximity to the production department.

I think that the actual situation of many companies can be classified into two cases.

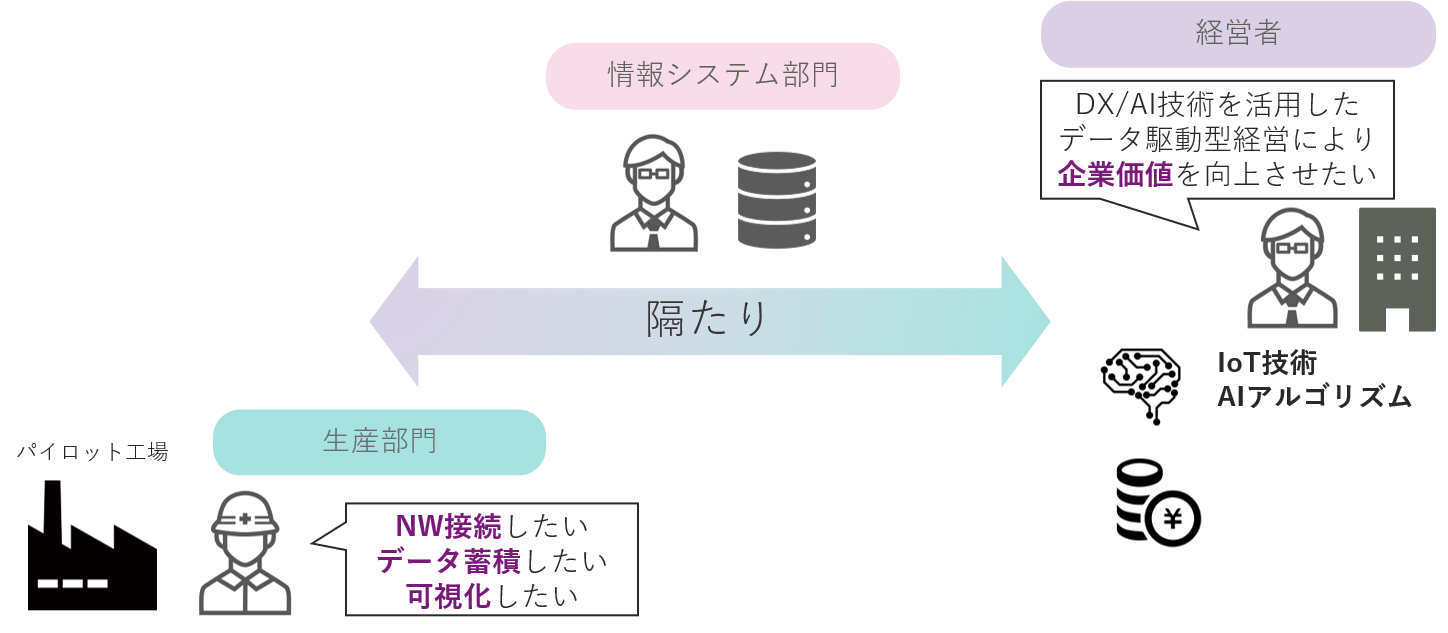

case 1

・In order to meet the demands of the production department, we visualized changes in production volume and the operation status of equipment based on equipment operation data and production counter values that can be easily obtained from production equipment.

・However, only the individual request of the person in charge of the production department was realized, and the business process of production activities was not included.

・As a result, the effects and value expected by the information system department could not be created.

case 2

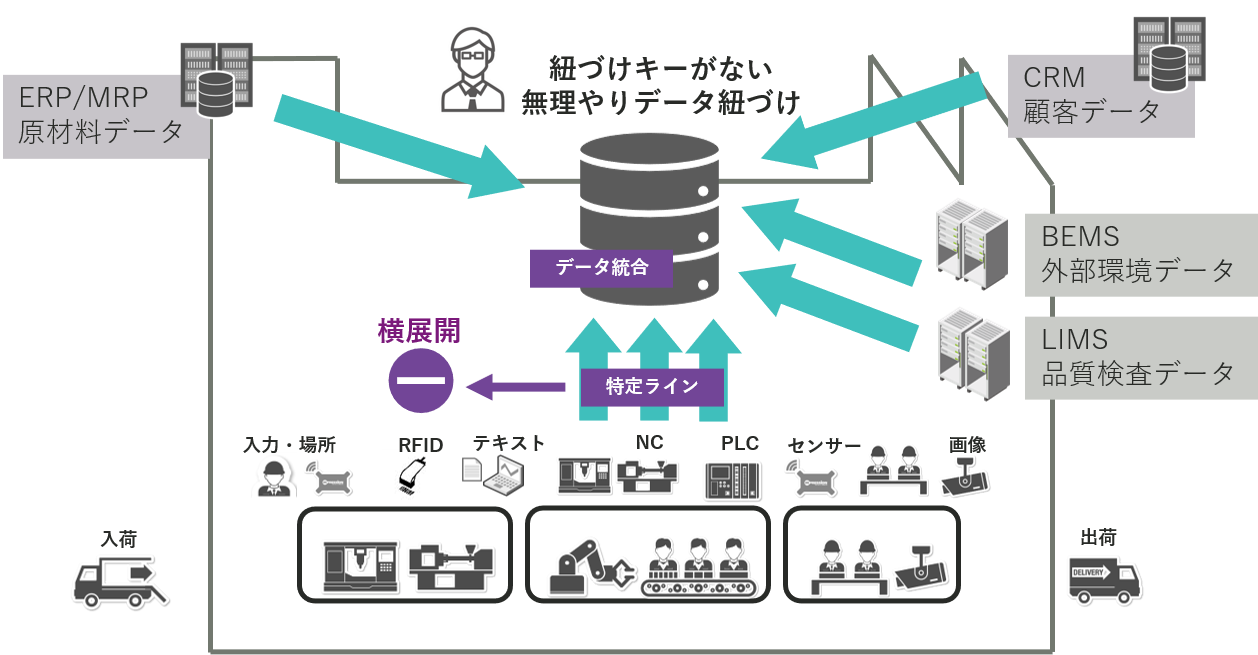

・The information system department worked together to realize data integration related to manufacturing.

・There was a high diversity of data at the manufacturing site, and there was no choice but to force data integration.

・As a result, the system became difficult to deploy horizontally to other processes, and the information system department continued to spend man-hours on the operation side.

What skills are required to promote smart factories?

We talked about smart factories from the perspective of the information systems department, and what Macnica has often visited while involved in various smart factory promotion projects.

From here, I would like to consider the elemental technologies required to promote smart factories in the first place.

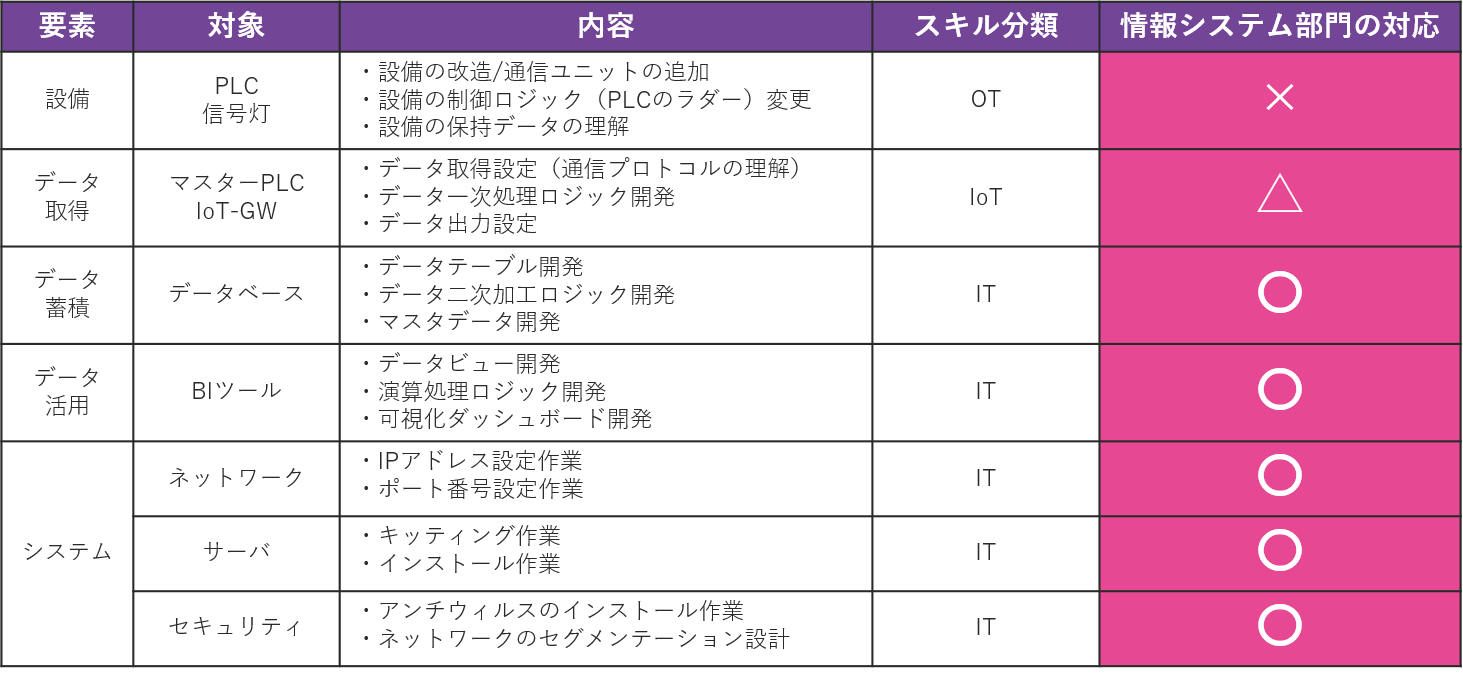

The technical elements associated with the digitization of production sites can be organized into production equipment, data acquisition from production equipment, accumulation of acquired data, utilization of accumulated data, and a system that makes these work as a mechanism. And the technology itself that is needed is nothing more than a technology that has been used in data utilization for a long time, rather than a recent technology such as AI. However, the technical field is so wide that it cannot be covered by a specific department of a company.

From the standpoint of the information system department, among the technical elements accompanying the digitization of the production site, isn't it easy to handle areas such as databases, BI tools, and systems in general?

Role of the production department in the smart factory promotion project

Then, what kind of role should the information system department involved in the smart factory promotion project participate in? Also, what should the smart factory promotion leader ask the information system department, who is a project member, to divide roles well?

At Macnica, while involved in various smart factory promotion projects, we believe that the information systems department's role in smart factory promotion projects can be summarized as follows.

● Evaluation and selection of introduction system

● Setting company policies and information for the introduced system

● In-house development for ease of use at the production site (core system linkage, etc.)

For the success of the medium- to long-term smart factory promotion project, it is necessary to secure human resources for the information system department. In particular, in the information system department, it is difficult to allocate man-hours to new projects in response to the "SAP 2025 problem (2027 problem)". It is important to define the role of the information systems department in

Information on the white paper that further digs into the points of this article

Regarding the process of successful smart factory promotion project,

For more information, please download this document.

Supporting quick start & quick win of smart factory

DSF Cyclone connects manufacturing results and production plans with structured data to realize a highly productive factory.

It can be introduced step by step from the manufacturing site, making it possible to expand to the entire company while rotating the Kaizen cycle.