Introduction

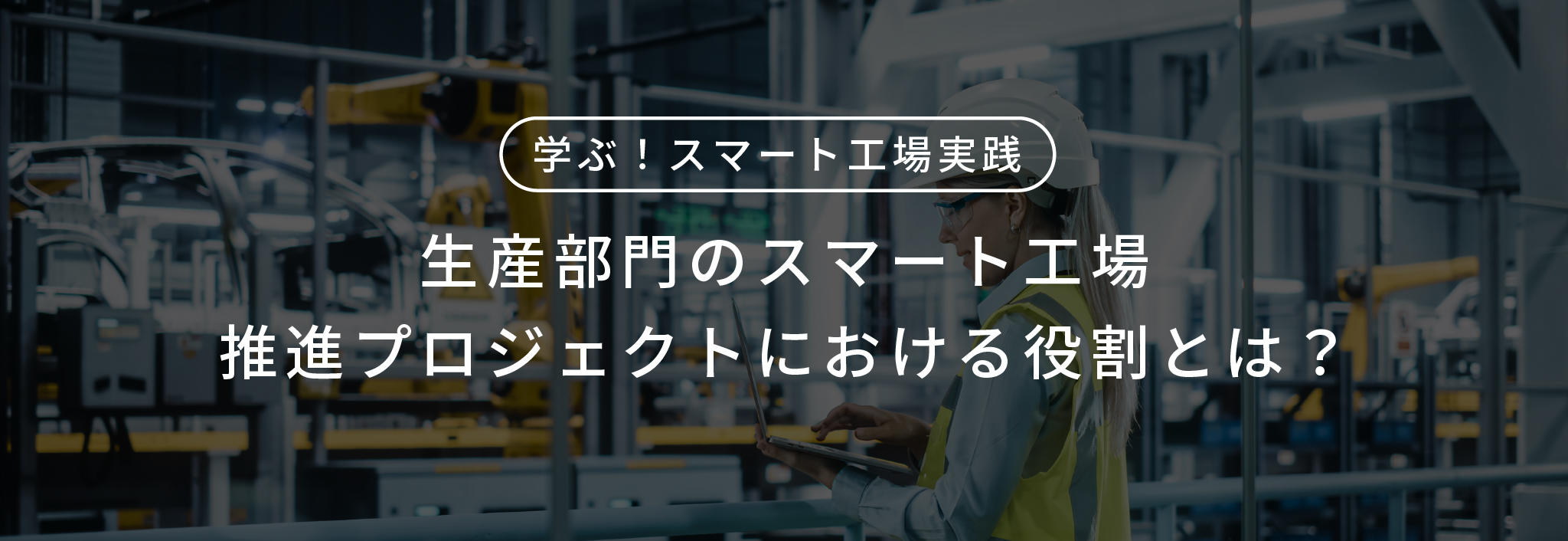

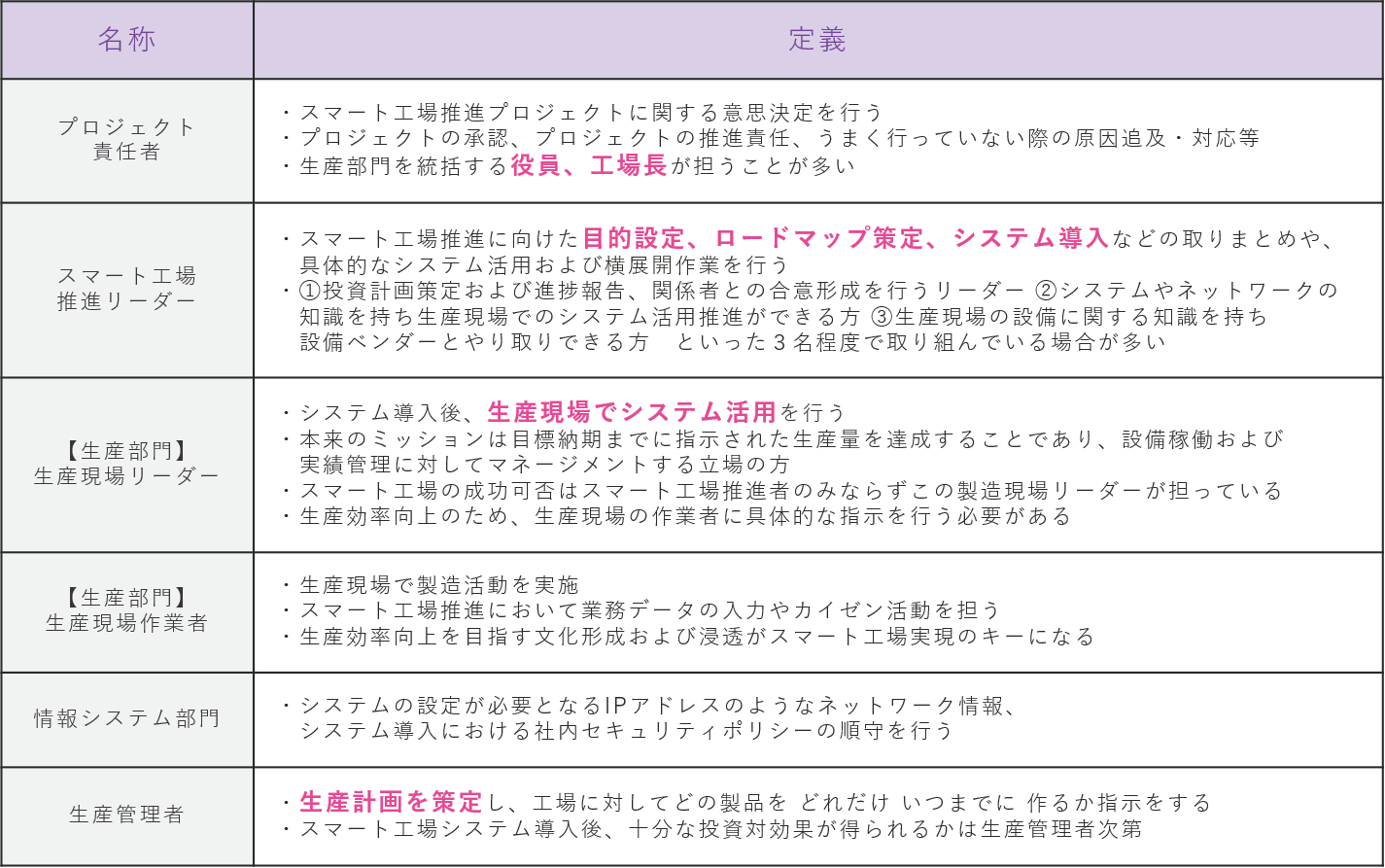

The smart factory promotion project is a highly complex project in which people in various positions are involved.

In this column, how does the production department view the digitization of the production site as they proceed with the smart factory promotion project? What should be defined as the role of the production sector? I would like to discuss with you about

This article discusses how to successfully implement a highly complex smart factory promotion project.

・Production Department: How should I be involved in the project?

・Smart factory promotion leader: How should the production department be involved in the project?

I will explain the above two points.

How does the digitization of the shop floor look from the production department?

1. Hard to understand specific actions

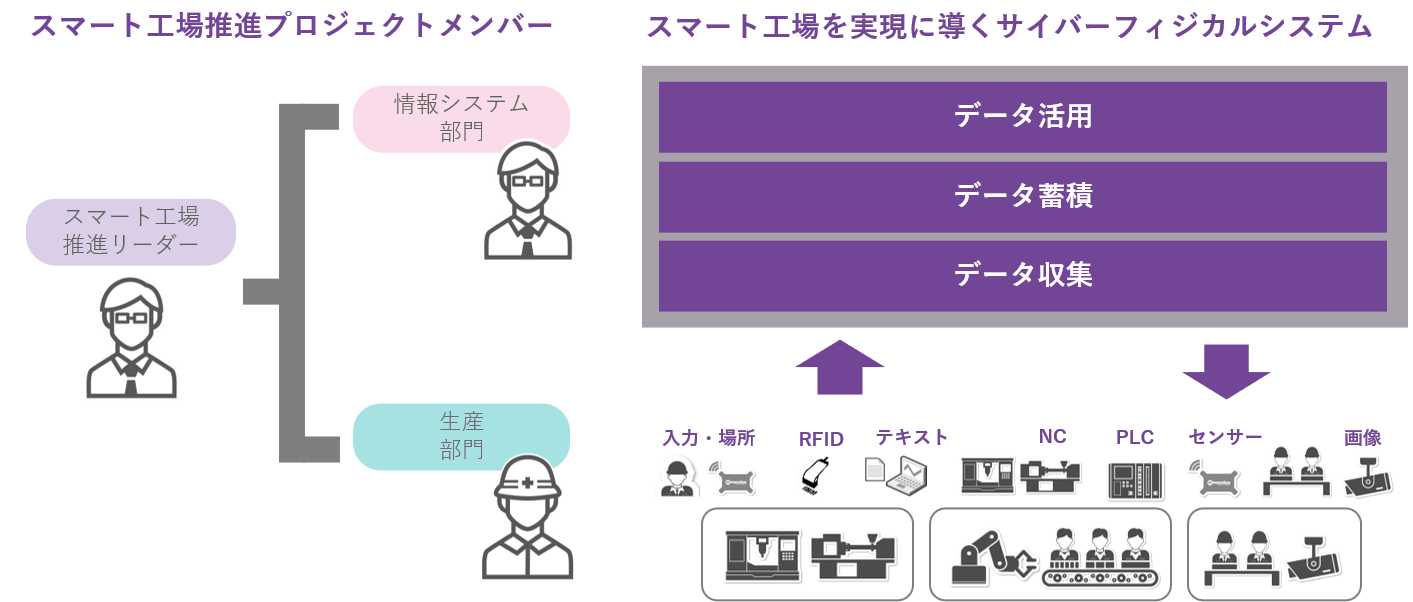

I believe that people in the production department are working on remodeling equipment and acquiring single equipment data as part of their daily work. Specifically, there are probably many people who change PLC ladders and do simple tabulation work using Excel.

On the other hand, when it comes to constructing a system that utilizes data from a wide manufacturing site consisting of different production facilities, making full use of an information network, many people may be at a loss as to where to start.

One of the objectives of the smart factory is to enable anyone, anytime, to easily achieve what the production department was originally working on in a limited range, such as a single line, with a standard and unified system for the entire production process. is.

However, the technical elements of the information system that are necessary when considering systemization are rarely involved in the daily work of the production department. The reality is that there are many.

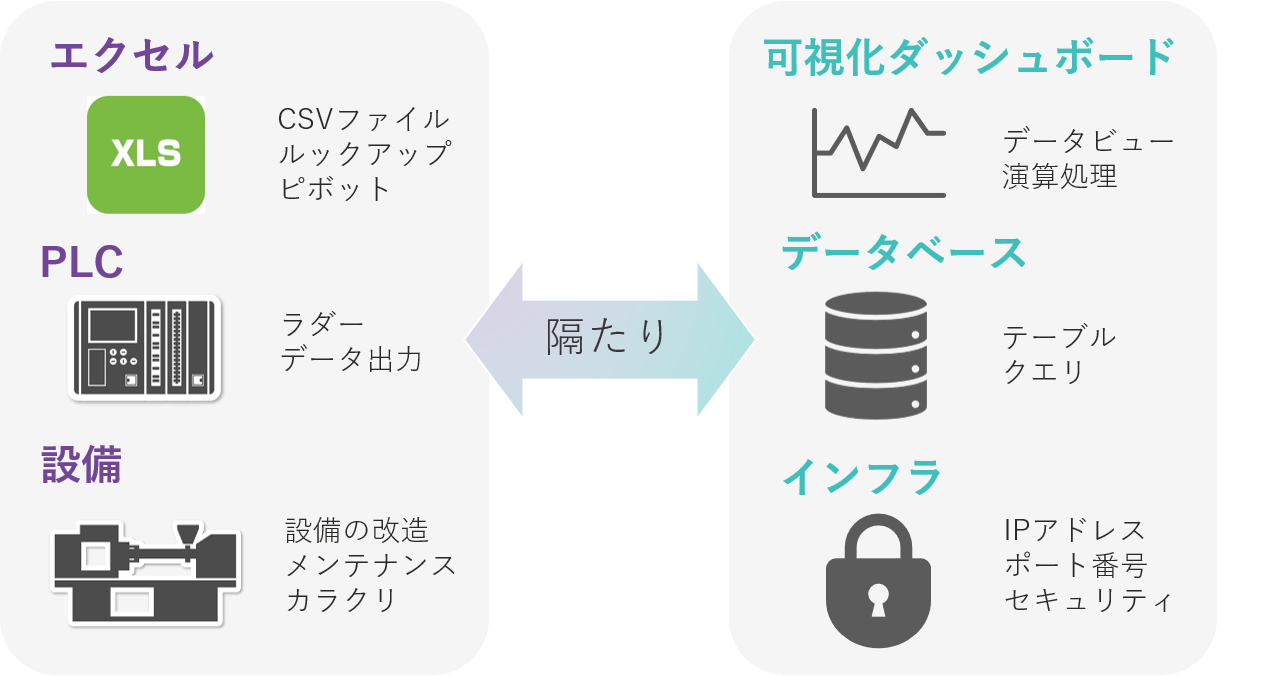

2. I feel a distance from the slogans of the head office and the management department

Recently, the words IoT, AI, DX, and digital transformation have spread widely, and in the company management (factory management) of the manufacturing industry, the improvement of corporate value through the use of data has become widely touted. In addition, in the production management department, we have been aiming to improve production activities under the slogan of improving productivity even before we became aware of this digital age.

However, from the point of view of people in the production department, there are many things that don't seem very familiar to them, even if they say that they are improving corporate value and productivity.

Of course, the people in the production department are working hard to ensure that the target production volume is produced on the production line they are in charge of on a daily basis with a high yield and by the deadline. However, since individual people in the production department are engaged in manufacturing activities on a single line that is part of the production process, even if they say "productivity x % improvement", what should they do specifically? I often hear that it is difficult to convert from one to another, and it is difficult to agree with smart factories that aim to improve productivity.

3. "Visualization" makes me think "Is it too late?"

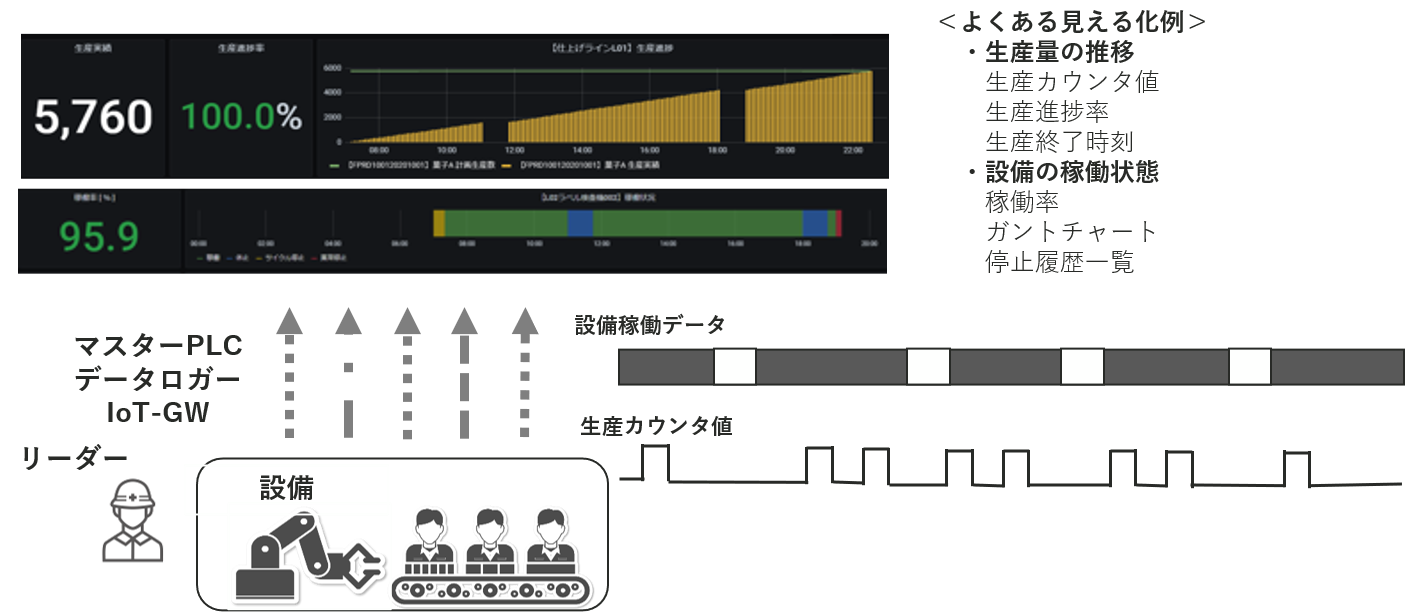

It's been more than five years since smart factories began to be called smart factories, and I'm guessing that most production departments are working on data utilization based on facility data? Specific activities include visualization of changes in production volume and the operational status of equipment based on equipment operation data and production counter values that can be easily obtained from production equipment.

Under such circumstances, if you try to promote digital utilization of manufacturing sites by promoting smart factories, it is important that there are benefits for the production department and that the initiative itself is highly convincing and easy to agree with.

What skills are required to promote smart factories?

We talked about smart factories from the perspective of the production department, and what Macnica has often visited while involved in various smart factory promotion projects.

From here, I would like to consider the elemental technologies required to promote smart factories in the first place.

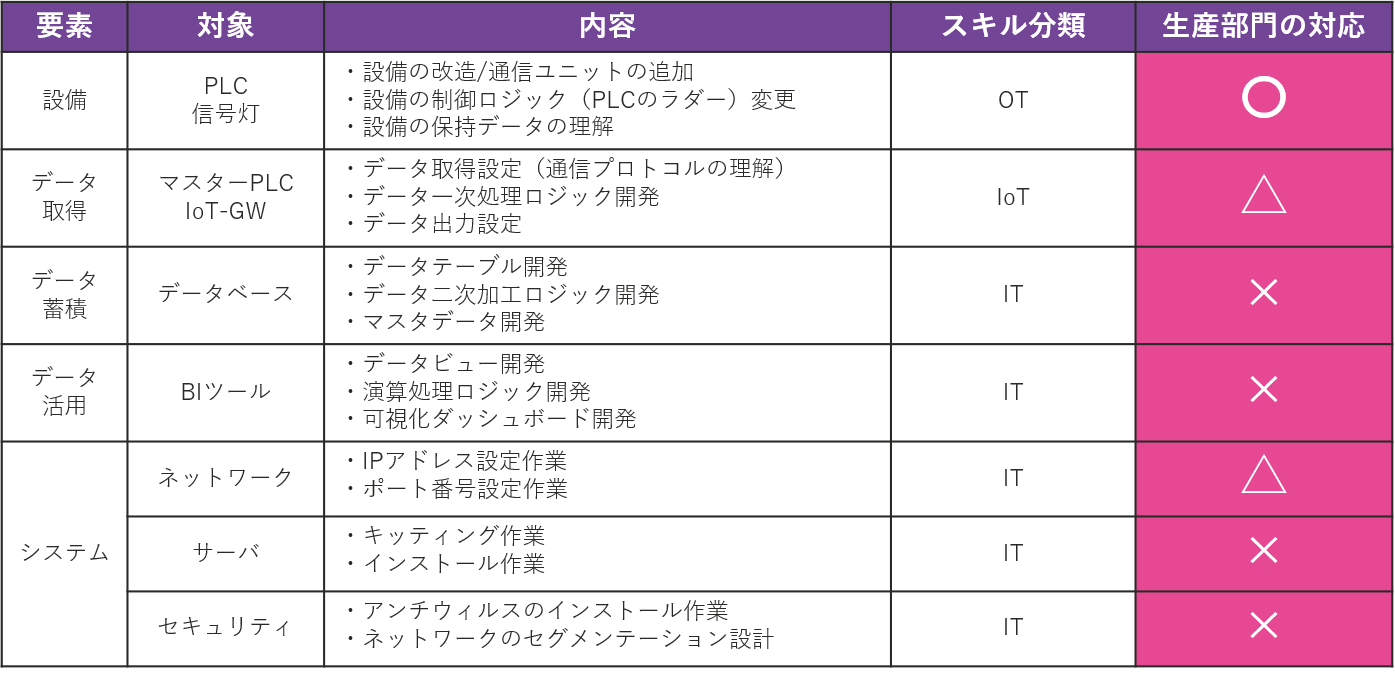

The technical elements associated with the digitization of production sites can be organized into production equipment, data acquisition from production equipment, accumulation of acquired data, utilization of accumulated data, and a system that makes these work as a mechanism. And the technology itself that is needed is nothing more than a technology that has been used in data utilization for a long time, rather than a recent technology such as AI. However, the technical field is so wide that it cannot be covered by a specific department of a company.

From the standpoint of the production department, among the technical elements accompanying the digitization of the production site, isn't it easier to deal with areas such as the production equipment itself and data acquisition from production equipment such as master PLCs and IoT gateways?

Role of the production department in the smart factory promotion project

So, what kind of role should the production department involved in the smart factory promotion project play? Also, what should the smart factory promotion leader ask of the production department members who are project members so that roles can be shared effectively?

At Macnica, we are involved in a variety of smart factory promotion projects and believe that the production department's role in these projects can be summarized as follows:

● System application and deployment in the responsible line

● Data input and utilization in daily production operations at the production site

● Apply the system (including changes) so that it is easy to use at the production site

For the success of the medium- to long-term smart factory promotion project, it is essential to develop digital human resources in the production department. In order to develop strategic digital human resources in the production department, it is important to define the role of the production department in promoting digital utilization at the production site.

Information on the white paper that further digs into the points of this article

Regarding the process of successful smart factory promotion project,

For more information, please download this document.

Supporting quick start & quick win of smart factory

DSF Cyclone connects manufacturing results and production plans with structured data to realize a highly productive factory.

It can be introduced step by step from the manufacturing site, making it possible to expand to the entire company while rotating the Kaizen cycle.