DSF Cyclone has been recently established by the Japan Plant Maintenance Association, a public interest incorporated association.

Selected for the “TPM Excellent Product Award (Effective Award)”!

What is DSF Cyclone?

The DSF Cyclone

Connect manufacturing results and production plans with structured data

Realize a highly productive factory.

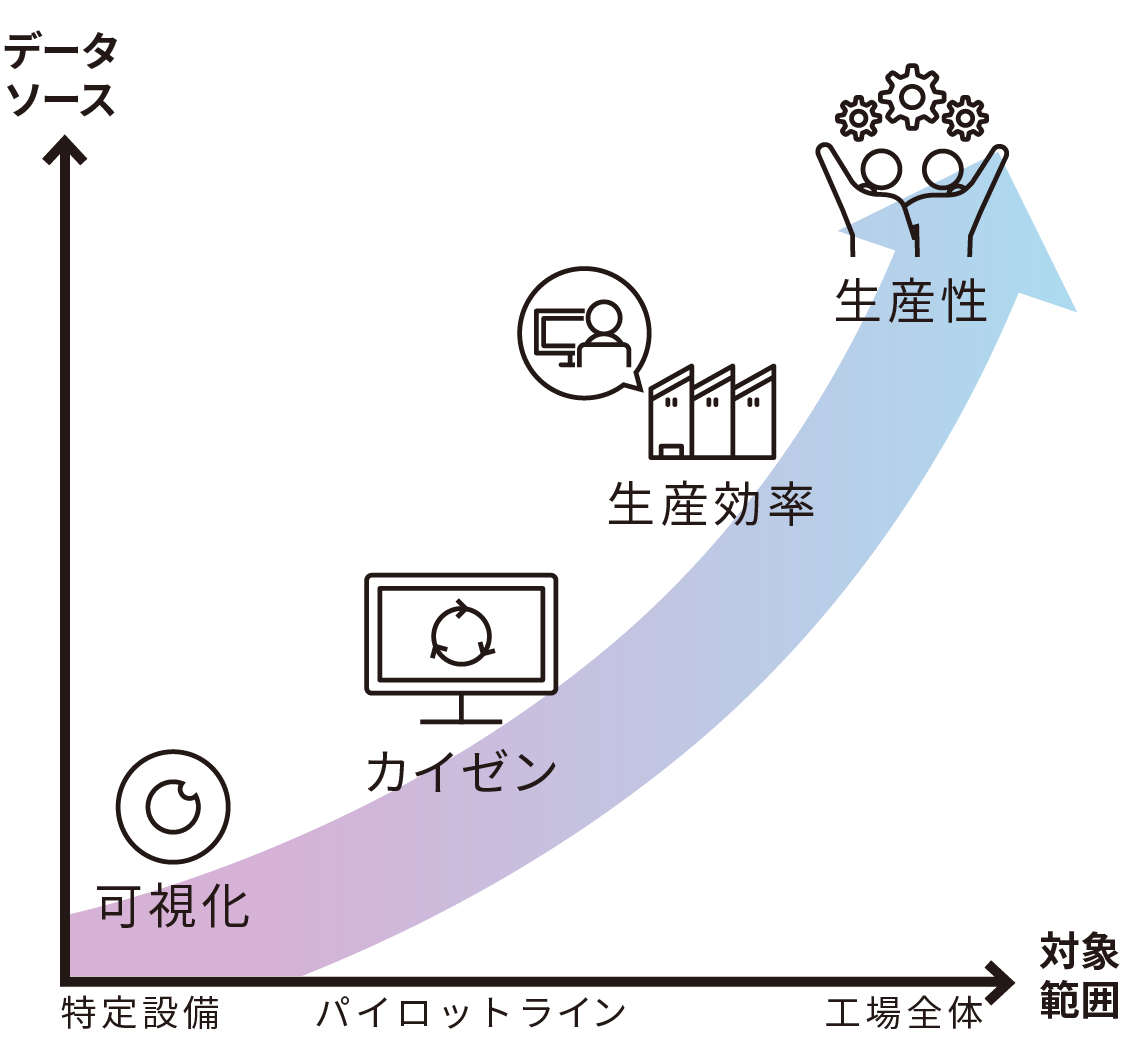

It can be introduced step by step from the manufacturing site,

While running the kaizen cycle

Enables expansion to the entire factory.

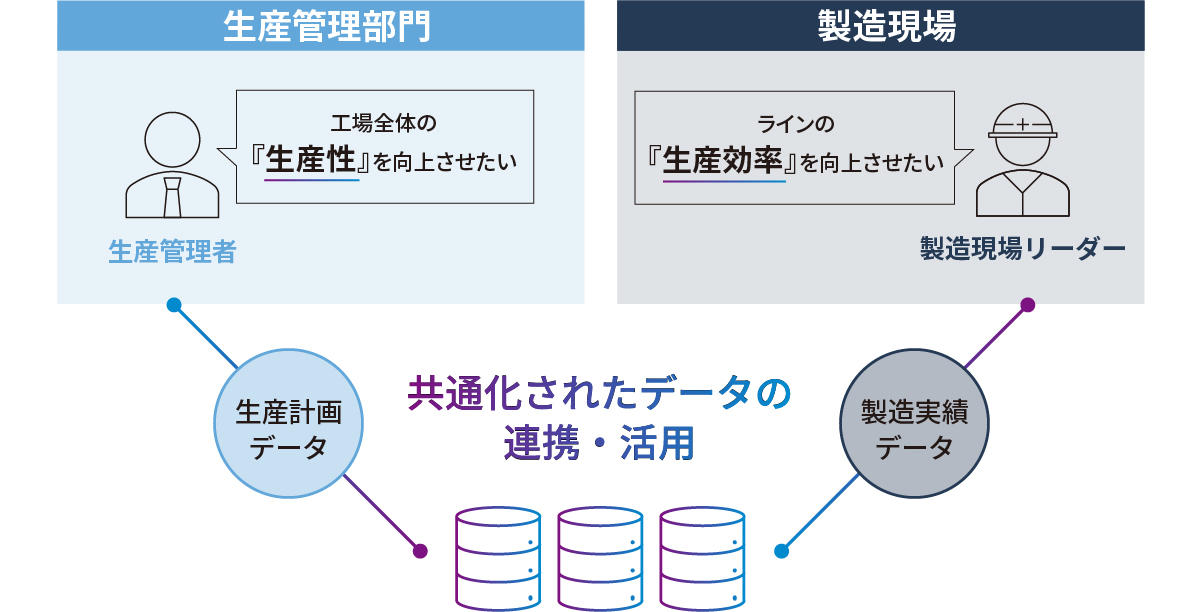

Feature 1: "Production manager" and "manufacturing site" are connected by data

By accumulating the data of each department as structured data, it is possible to utilize data across departments.

*Proceed to the application form for video viewing.

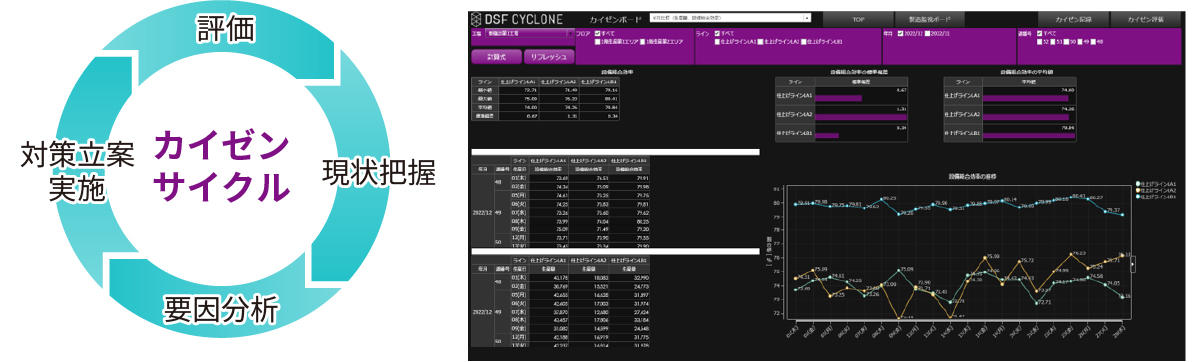

Feature 2: Support analysis and countermeasures with an awareness of the Kaizen cycle

A dashboard that not only visualizes data, such as loss analysis by production line, but is also conscious of the Kaizen cycle beyond that

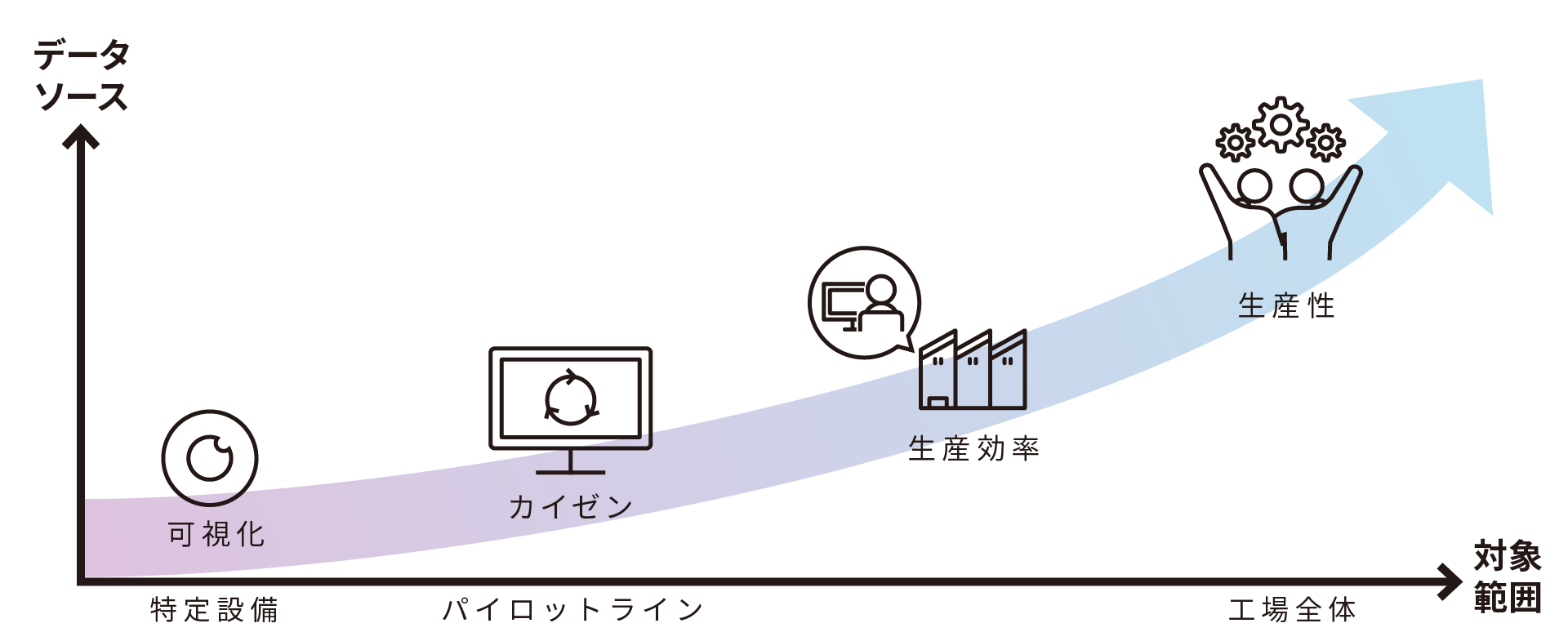

Feature 3: Can be deployed to the entire factory

It can be introduced step by step from the manufacturing site and can be expanded to the entire factory.

Four phases of smart factory realization

A smart factory is difficult to obtain a clear return on investment.

We will introduce the flow of introducing it step by step from the manufacturing site and expanding it to the entire factory while rotating the Kaizen cycle, divided into four parts.

Phase 1

aim settingPhase 2

Selection of pilot linePhase 3

Roadmap formulationPhase 4

Consensus building among stakeholdersFlow until service introduction

|

Phase 1 |

hearing

Wall hitting session (3 times) |

|---|---|

|

|

|

|

Phase 2 |

Discussion (2-3 times)

|

|

|

|

|

Phase 3 |

Setting/Test

training

|

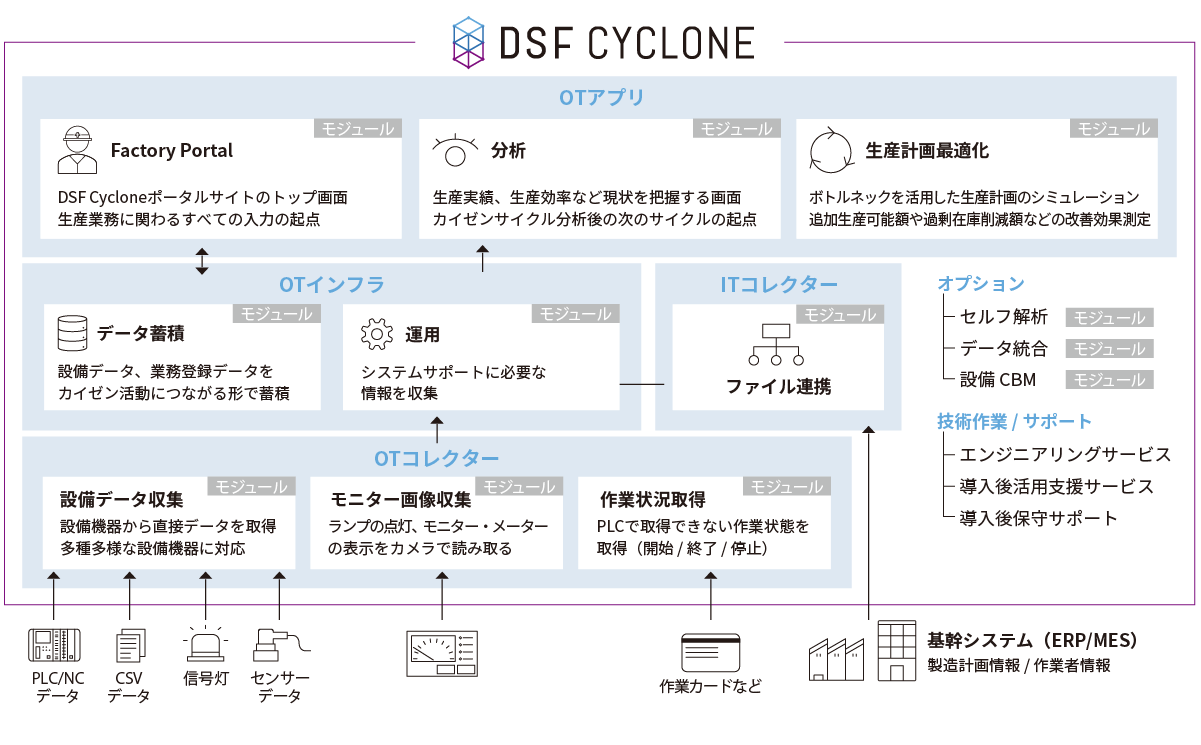

System component diagram

It can be used by freely combining modules for each function.

We provide the best environment for each customer.

Case

Case

Introduction example of Togo Seisakusho Co., Ltd.

Promote overall optimization of the entire factory from an environment that is partially optimized for each process. DSF Cyclone functions as a common yardstick, using comprehensive equipment efficiency as a new indicator.

Document

white paper

Maximizing Production Efficiency & Productivity Series 1

For those who start promoting smart factories

4 phases of DX starting from the field and return on investment

*Application is required to download.

white paper

Maximizing Production Efficiency & Productivity Series ②

Smart factory target index

Think about three settings that are conscious of departmental organization and their interlocking system

*Application is required to download.

white paper

Maximizing Production Efficiency & Productivity Series ③

Application of Total Productive Maintenance (TPM®) to smart factories

Deep digging for target indicators! Leverage TPM to eliminate loss

*Application is required to download.

white paper

Maximizing Production Efficiency & Productivity Series ④

System selection in smart factories - package utilization vs. scratch development

Explain the trend of mounting methods that change dramatically!

*Application is required to download.

white paper

Maximizing Production Efficiency & Productivity Series ⑤

Application of Theory of Constraints (TOC) to smart factories

Introduction of an approach to achieve total optimization of the manufacturing system

*Application is required to download.

white paper

Maximizing production efficiency & productivity Series ⑥

In what unit should factory data be used?

Based on actual experience, we will introduce important points in data utilization and approaches to eliminate rework.

*Application is required to download.

On-demand video for smart factory promotion

movie

Overcoming social change through digital technology

The present and future of the factory

movie

Maximize production efficiency!

How to start a site-friendly smart factory

movie

How to collect and use "useful data" [with demo]

How to increase factory productivity and profitability

Seminar

There are no upcoming events scheduled. We are always available for individual consultations.

Click here for service inquiries