INDEX

-

I want to know more in the video!*The video overview and viewing application page will open.

Are you considering such an initiative?

▽

I can see the progress of the plan

▽

Product can be tracked

▽

process can be tracked

If any of these apply to you

Maybe MES can solve it! ?

However, hurdles that tend to occur

Since the system configuration is partially optimized, the overall system image cannot be seen.

The introduction of MES has a wide range of impact on both the system and the department, and no progress has been made in considering it.

It is not clear what kind of effect the introduction will have

I have a direction, but I don't know how to proceed

It is important to experience it first.

What you can do with the DSF-MES introduction trial service

Early assumption of introduction image by workshop

Conceptual design with future expandability in mind

Smooth project promotion in line with conceptual design

to support the service

300+

Digital Manufacturing support results

Executable

do concept design

IT/OT

professional

high expectations and load

DX human resource development

Knowledge to support

Use Case

Information equipment manufacturer Company A

●Why did you contact us?

Inquired about the necessity of MES and how to introduce it

● Resolved issues

- I do not understand the image after installing MES

- It is not possible to narrow down or clean business processes that should be systematized with MES

●What I did

- Experience MES introduction by implementing MES execution demonstration through workshop

- Create a “To-Be Scenario” after introducing MES

●Effect

- I was able to grasp the specific cost and image of introducing MES.

- We were able to narrow down and select the business processes that should be MES systemized in a short period of time.

Medical manufacturer company B

●Why did you contact us?

We consulted about the introduction method at the MES study stage.

● Resolved issues

- Can't decide whether to use package MES or scratch development

- I do not know the cost, period, personnel, etc. required for introduction

●What I did

- Hearing about current business processes

- Create a “To-Be Scenario” after introducing MES

- Experience MES introduction by implementing MES execution demonstration through workshop

●Effect

- We were able to decide whether to use scratch development or package MES (decided to introduce package MES → switch to MES introduction support service)

- We were able to create a concrete roadmap for the introduction of MES.

- I was able to understand the suitability of the company's business processes and packaged MES solutions, and I was able to specifically consider the direction of future efforts.

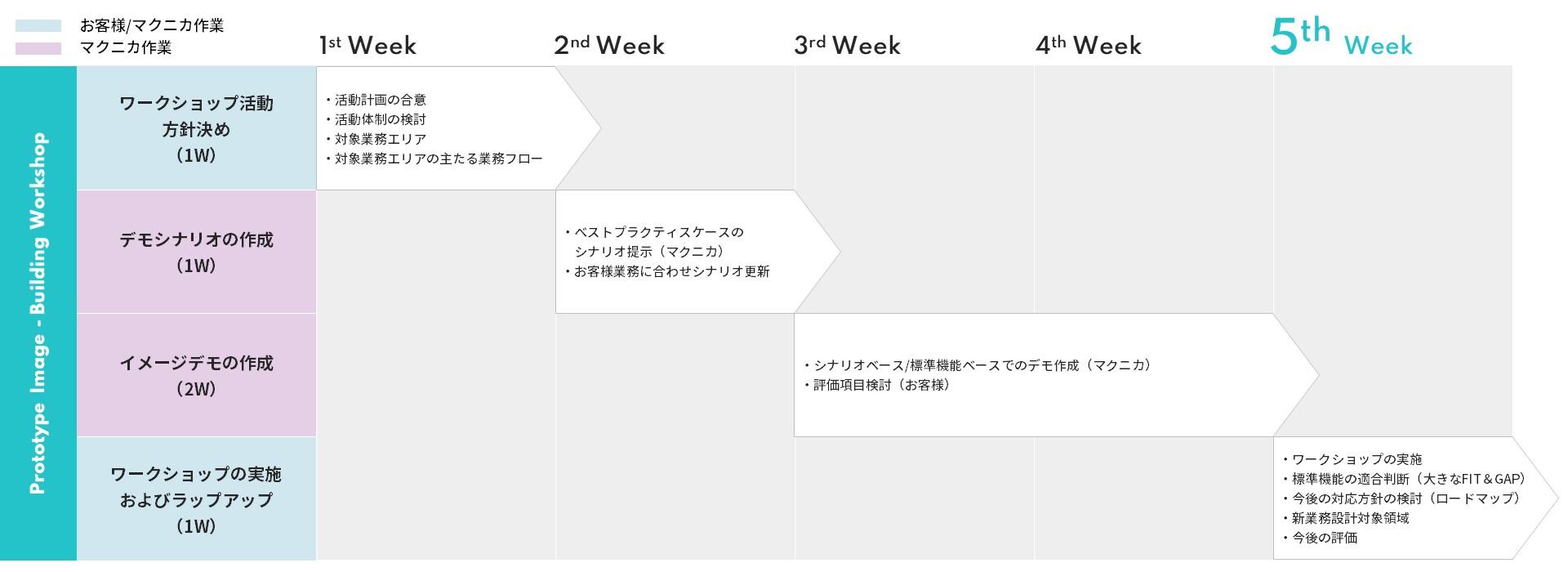

workshop

In 5 weeks, you can experience/verify a working MES!

*Slide sideways to see

I want to know more in the video

The first step of difficult manufacturing DX~ A concrete approach centered on "people" that opens up new opportunities ~

While many companies are shifting their focus to "how to realize DX", we will discuss the difficulties of DX unique to the manufacturing industry, the points that lead to project failure, and three specific approaches with actual examples. I will explain.

In addition, we will also introduce a service that enables the introduction, effective utilization and operation of Plant Simulation and Opcenter in a short period of time.

※Application is required for viewing