Digital twin process optimization service

By recreating the factory in virtual space, it is possible to digitally verify various manufacturing performance before implementing improvements in the real factory. This is also effective for bottleneck analysis in 4M. Additionally, it is possible to repeat hypothesis testing as many times as necessary to achieve KPIs such as production volume and delivery dates.

By digitally reproducing the actual factory using a digital twin *, it is possible to optimize processes and improve production throughput.

At Macnica, we offer services to help customers use digital twins more quickly, easily, and firmly, and support customers in accelerating their DX efforts.

*Digital twin is a technology that reproduces real space in virtual space, and is a technology that makes it possible to predict various events and phenomena by ``manipulating time,'' which is impossible in real space.

white paper

We have summarized the details of what a digital twin is, how to use it, examples, and the effects of its introduction.

Please take a look at it as the first step of the digital twin!

*Registration required for viewing/downloading

INDEX

-

Want to learn more about digital twins in the video!*The video overview and viewing application page will open.

3 benefits of digital twin

● Visualization of the current factory

By collecting 4M information and visualizing it on a simulation, you can understand the current situation.

It is useful for discovering bottlenecks and drafting improvement plans.

● Hypothesis verification of improvement plan

If it is on the simulation, you can consider improvement proposals as many times as you like.

Wasteful investment and man-hours can be reduced because more reliable improvement methods can be reflected in the actual factory.

●As a communication tool with stakeholders

By utilizing simulation data, information can be shared among stakeholders.

Regarding DX initiatives that are complex and cross multiple departments, information exchange is active among related departments, which is a persuasive material for management.

An example of problem solving

It helps to solve the following 4M issues that occur in the factory!

Case 1: Inventory adjustment

-

Calculation of required number of parts

-

Work-in-progress inventory adjustment

-

Consideration of where to store parts/work in progress/finished products

Visualize and analyze "when", "where", and "how much" of parts and work-in-progress through simulation to reduce excess inventory

Case 2: Equipment use

-

New production line design

-

Judgment of equipment expansion/reduction

-

Consider automation

Judge rational capital investment by analyzing bottlenecks in new/existing production lines in advance using simulations

Case 3: Staffing

-

Allocation of personnel (qualifications, skills)

-

labor saving

-

Traffic line optimization

『スキル』、『役割』、『動線』を考慮した様々な人員配置をシミュレーションで検証し、人員リソースと配置を最適化

Case 4: Process adjustment

-

Planning the production schedule

-

Determination of production lot size

-

Costing

Plan the optimal input order and lot size for various conditions such as delivery date, throughput, cost, etc. with the automatic optimization function (GA)

Case

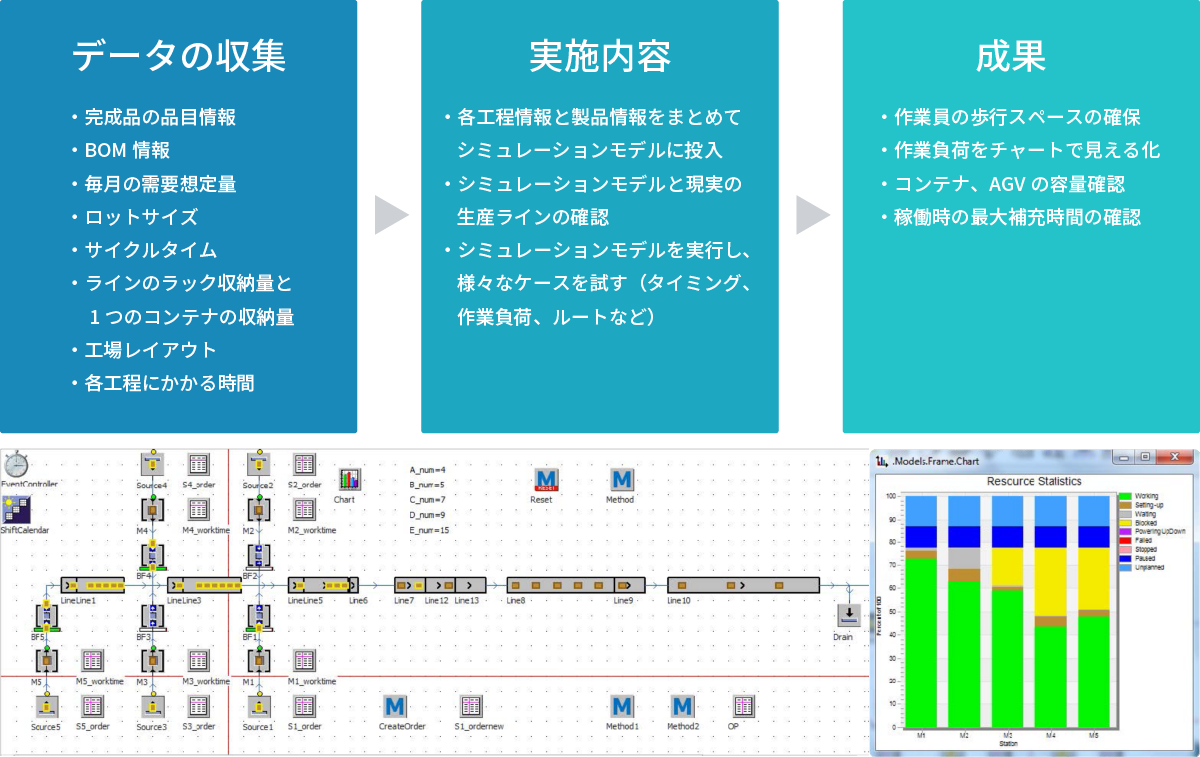

Optimize electronics assembly manufacturing with manufacturing simulation

■ Electronics manufacturer assembly plant

Realize optimization of daily production efficiency by reproducing delivery dates, processes, equipment usage order, equipment capacity, worker ability, etc. on simulation software.

■ Issues

| ・ | We are planning the process in Excel, but we rely on intuition and experience, and it takes time. | |

| ・ | I want to optimize the movement of people and AGVs | |

| ・ | I want to find out where the bottleneck is in the production process |

■ Results

| ✓ | By simulating the production line in advance, the movement of existing equipment can be optimized so that anyone can see it. |

| ✓ | Even for sudden orders such as sudden orders, we can start production after creating an optimal plan on the simulation. |

| ✓ | Optimize worker movement |

Introduction flow example

|

How to proceed with the project |

service |

|

|

-Phase 1- |

Grasping of current issues/examination of simulation effects/selection of optional services/cost estimation |

consulting |

| ▼ | ||

|

-Phase 2- |

Process information (flow, layout, etc.) / Equipment information (processing time, setup time, etc.) / Worker information (number of people, role, etc.) |

consulting |

| ▼ | ||

|

-Phase 3- |

Objective setting / Functional design / Model design / Review |

digital factory |

| ▼ | ||

|

-Phase 4- |

Select a simulation software license that matches your application |

simulation |

| ▼ | ||

|

-Phase 5- |

Usage Training / Model Design Method Training |

training |

| ▼ | ||

|

-Phase 6- |

Technical FAQ / Regular meeting / Model accuracy improvement / Model range expansion |

Paid support |

Digital twin introductory video collection

We have prepared a page where you can watch all 6 digital twin introduction videos.

If you want to know more about the digital twin, or if you want to see how the simulation is performed with the software "Plant Simulation", please take a look!

*Application is required to watch the video.