Macnica (hereinafter referred to as Macnica) is a total service/solution provider in semiconductors, networks, cybersecurity, and AI/IoT (Head office location: Yokohama City, Kanagawa Prefecture, President: Kazumasa Hara, capital: 11,194 million yen) is pleased to announce that it has entered into a reseller agreement for the Digital Industries software products of Siemens AG (Headquarters: Munich, Bavaria, Germany, CEO: Joe Kaeser).

Based on this, Macnica, as a strategic partner of Siemens, will sell the product in Japan and provide modular services*1 for the manufacturing industry based on the product, targeting companies aiming to become smart factories. We have started.

In recent years, there has been a growing trend in the manufacturing industry to utilize advanced digital technologies such as IoT and AI at manufacturing sites toward smart factories.

However, although progress is being made in tackling individual issues such as the visualization of the operational status of equipment in the process, there are only a few companies that have implemented visualization of the entire factory, including the overall manufacturing process and the operational status of personnel. This is the current situation.

In addition, in order to create a smart factory that efficiently realizes variable-variety, variable-volume production in response to changes in the market environment, it is most important to utilize digital technology that considers not only partial optimization efforts but also overall optimization.

Under these circumstances, Macnica participated in the partner program of Siemens' cloud service open IoT operating system "MindSphere™" in September last year, entered into a reseller agreement, and is developing its business as a digital platform for services for the manufacturing industry. Doing.

Now, by linking Digital Industries software products with which we have newly concluded a reseller agreement and "MindSphere™," as well as combining Macnica 's strengths in data collection and analysis at manufacturing sites and AI, we will be able to provide digital support for manufacturing preparation and manufacturing sites. Realize twins.

"Plant Simulation™", one of the digital industries software products that we have started handling this time, is a production simulation software that realizes a digital twin of manufacturing preparation and manufacturing sites. By reproducing the flow of goods in a form close to reality, it is possible to perform high-speed simulations for efficient bottleneck analysis and variable-variety variable-volume production.

In addition, since it is possible to link with "MindSphere™", it is possible to construct an optimal production plan in a short period of time by analyzing the gap between simulation and actual production.

Another launch, Opcenter™, manufacturing operations management (MOM) software, is a holistic solution that enables a complete digitalization strategy for manufacturing operations.

The Opcenter™ portfolio provides end-to-end visibility into production, enabling decision makers to easily identify areas for improvement in both product design and related manufacturing processes, resulting in smoother production. enable you to make the operational adjustments necessary to operate efficiently.

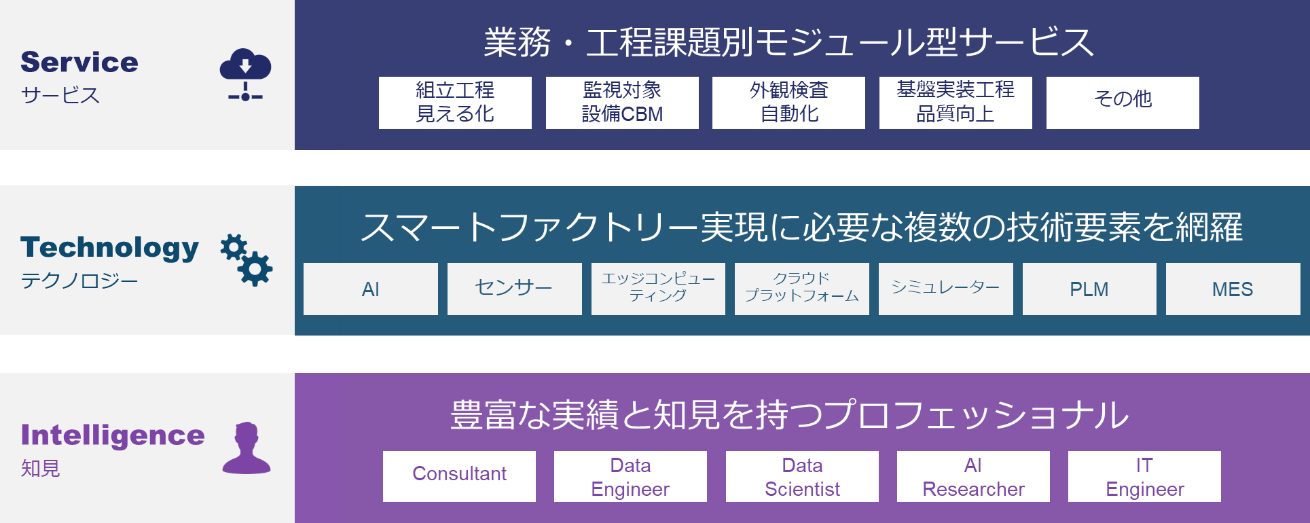

In addition, Macnica has already started providing an integrated service for the manufacturing industry called “Digital Synergy Factory.macnica.ai,” which is a modular service for the manufacturing industry* based on Siemens Digital Industries software, with which it has recently concluded a reseller agreement. We will also start offering 1.

<Overview of Digital Synergy Factory.macnica.ai>

*1: Modular service for the manufacturing industry based on this product

■Digital twin process optimization service

The customer is Plant Simulation™ By using ``, it is possible to perform simulations and optimize processes before starting production. At Macnica, we provide support as a service for customers to realize their own digital twins and continuously operate them, focusing on creating models for simulation and training at the time of implementation.

■ MES (manufacturing execution system) introduction service

We will introduce the world's most advanced Siemens MES (Manufacturing Execution System) to the manufacturing industry, centered on the automobile, medical equipment, and semiconductor industries, where traceability and quality control are required.

We also support installation at multiple sites, including overseas.

At Macnica, consultants with deep knowledge of manufacturing sites, engineers, and data scientists collaborate with companies aiming to create smart factories to achieve digital transformation, and we have technology for the manufacturing industry that boasts an overwhelming share of the global market. As a strategic partner of Siemens, we will strongly promote smart factories.

*Company names and product names mentioned in this text are trademarks or registered trademarks of Macnica and each company.

*The information published in the news release (including product price, specifications, etc.) is current as of the date of announcement. Please note that the information may be subject to change without prior notice.

For more than 170 years, Siemens AG has been a global technology company that stands for engineering excellence and innovation, quality and reliability, and internationality.

It operates worldwide with a focus on the areas of electrification, automation and digitization.

Siemens is one of the world's largest providers of energy-efficient and resource-saving technologies, the world's number one producer of offshore wind farms, a leading supplier of combined cycle power generation, a leading provider of power transmission solutions and infrastructure.・A pioneer in solutions as well as industrial automation and software solutions.

In addition, Siemens' listed subsidiary, Siemens Healthineers AG, is a leading supplier of medical imaging equipment, such as computed tomography and magnetic resonance imaging systems, and a leader in clinical diagnostics and clinical information technology.

For the financial year ended September 30, 2019, sales were €86.8 billion and operating profit was €5.6 billion.

As of the end of September 2018, we have 385,000 employees worldwide.

More information about Siemens can be found at www.siemens.com.

Since its establishment in 1972, Macnica has provided cutting-edge semiconductors, electronic devices, networks, and cybersecurity products with added technological value.

In recent years, we have been developing new businesses in fields such as AI/IoT, autonomous driving, and robots, based on our traditional strengths of global cutting-edge technology sourcing and technology planning capabilities.

Going forward, under the slogan "Co.Tomorrowing," we will connect cutting-edge technology and Macnica 's intelligence to provide unique services and solutions, creating social value and contributing to the development of future society. .

the Company is headquartered in Yokohama, and we are developing our global business based on 84 bases in 24 countries around the world.

For details, please see the website (https://www.macnica.co.jp).