This article is recommended for those who

- Those who are considering/introducing the automation of the front work of the melting process furnace

- Those who are interested in disaster prevention in factories

- Those who are considering quality improvement due to the influence of noro

How long does it take to finish reading this article

3 minutes

Introduction

Hello. My name is Asami and I am a sensor solution creator.

Macnica proposes a thermal measurement system that uses infrared cameras and other devices.

In order to automate the slag removal work in the casting and melting process, we will share an example of how we visualized slag and realized work style reform.

Eliminate industrial accidents! Safely work in front of the furnace

In the melting process of casting, there is "furnace front work" that is done in front of the melting furnace.

The work in front of the furnace creates dust that affects the human body, and it is right next to molten metal that exceeds 1000°C.

Temperature measurement, component adjustment, sample collection, slag removal, etc. are very dangerous tasks.

Among them, "removing slag" is hard labor to manually remove tens of kilograms of slag.

If the slag is not removed, the quality of the casting will be greatly affected, and in some cases it can lead to losses of several million to tens of millions of yen. In terms of safety, there are also accidents that lead to health problems and occupational accidents due to inhalation of dust, and in the worst case, fatal accidents such as falling into a melting furnace.

Are you worried that you want to safely and stably remove this slag?

In order to safely remove slag, it is conceivable to use a slag removal device to remove slag automatically or by remote control. It is important to use sensors for

Look for the sensor

What kind of sensors should be used to determine the amount and location of slag?

The general idea is to use a visible camera that is readily available and relatively inexpensive.

We also tested whether we could actually see the slag in the melting furnace with a visible camera.

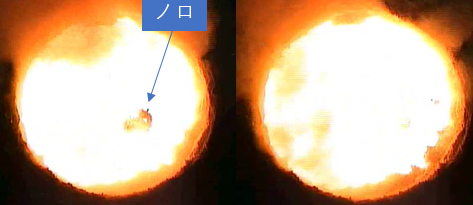

The results are shown in Figure 1.

Figure 1: Acquisition result of visible camera

The left side and the right side are photos comparing the photos in the same furnace with a difference of several seconds. Noro is visible on the left, but not on the right. In other words, depending on the timing, you may or may not see the slag.

Why is this happening? This is because fumes are emitted from the melting furnace.

With a visible camera, the slag on the molten metal may not be visible due to the fumes emitted from the melting furnace.

It's the same as you can't see the other side of the steam with your eyes.

This is how Noro looks!

Unfortunately, it seems that it is not possible to stably visualize the slag using a visible camera.

So Macnica used an infrared camera.

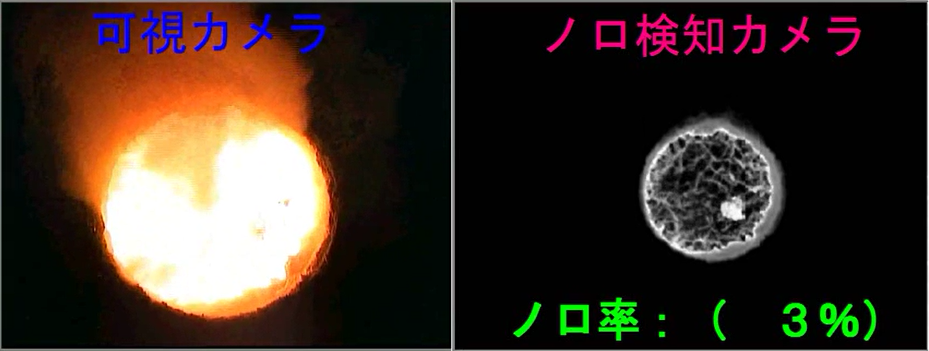

The results are shown in Figure 2. To make it easier to understand, I will display the visible and infrared images side by side.

Figure 2: Comparison image of a visible camera and an infrared camera (slag detection camera)

The image was obtained by using a visible camera and an infrared camera at the same time, and it can be seen that the infrared camera can see the slag that cannot be seen with the visible camera.

Why are infrared cameras immune to fumes?

An infrared camera is a sensor that senses the infrared radiant energy of an object.

Infrared radiant energy passes through the fumes and can be sensed, making the noro visible.

However, there may be people who say, "I tried an infrared camera before, but it didn't work."

This is due to the specs of the infrared camera.

We have an infrared camera to measure the temperature of hot iron, but it is affected by fumes.

Infrared cameras have specifications for measurement wavelengths, and it is necessary to select an infrared camera with a wavelength band that is not affected by fumes.

An infrared camera is a camera that senses the temperature (infrared radiant energy) even if you can see inside the melting furnace without being affected by fumes.

Isn't "molten metal" and "noro" almost the same temperature? I think some people think.

Actually, the temperature is almost the same.

However, objects have a measure of how much infrared energy they emit called emissivity.

Molten metal has low emissivity, while slag has a solid, dark, rusty metal-like surface with high emissivity.

(Even solid metals, such as polished aluminum, have low emissivity. Darkened or rusty metals have high emissivity.)

That's why you can see the difference in temperature.

An infrared image with temperature bars is shown in Figure 3.

Figure 3: Infrared image

You can see that the white part is slag and the temperature is higher than the molten metal.

Note that this solution is not intended to measure the exact temperature of the melt, so the displayed temperature is different from the actual melt temperature.

The actual temperature is assumed to be around 1400°C. If you want to accurately measure the temperature of the molten metal, you will also use a radiation thermometer.

Once you have visualized the slag, you need to quantify the amount of slag and judge whether it is okay to complete the slag removal.

We'll show you how to do that in our next tech blog.

What we found in this article

- Visualizing the slag is the key to automating the pre-furnace work in the melting process.

-

With a visible camera, the slag may not be visible due to the fume emitted from the melting furnace.

- Infrared camera can visualize noro without being affected by fumes