Time taken to read this article

5 minutes

Introduction

Hello, this is Moriri, who will be in charge of the 3rd installment. I usually make proposals to customers of machine tool manufacturers to increase the value of their products, centered on SENSPIDER, and to customers who are interested in smart factories, to propose systems that utilize AI/IoT.

Receiving the baton from KODAI, "Delivering the 'good things' seen at EMO 2019-Hannover autumn machine tool festival-" The third EMO to conduct an in-depth survey of technology trends in Germany, which advocates Industrie 4.0 In addition to what I saw and learned, I would like to report on what I felt.

What is umati?

First, I would like to talk about umati, which I introduced in the second EMO blog. At this year's EMO 2019, machine tools from various manufacturers were connected to a single system using umati, and actual operation information was collected in real time and visualized on a single dashboard.

Source: Umati Dashboard https://dashboard.umati.app/

Machine tool communication has been independently developed by each manufacturer, so the current situation is that each manufacturer has its own dedicated connection method and data format. Under these circumstances, if we wanted to create a system like this one, it would be necessary to develop software individually in order to centrally manage the data of various machines.

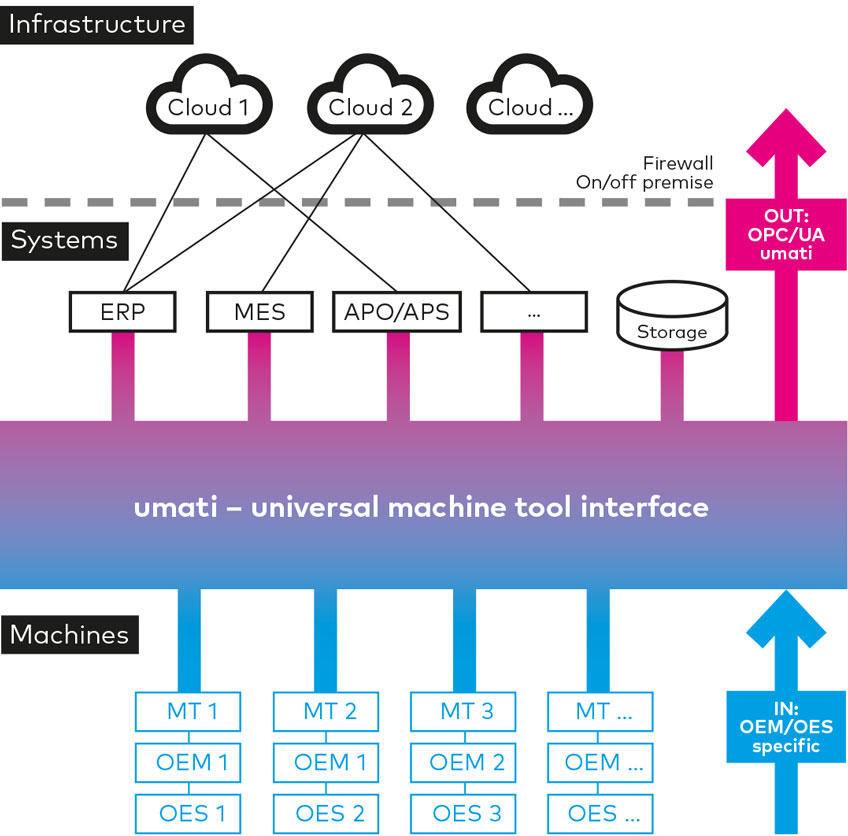

The information model, umati, solves this problem.

Source: VDW (German Machine Tool Builders' Association) website

https://vdw.de/en/technology-and-standardisation/umati-universal-machine-technology-interface/

Until now, machine information was handled in a free format, but umati uses a fixed format as the information model to increase the versatility of the data. Not only the data format, but also the meaning of the data symbols (for example, automatic control is '2' for manufacturer A, but '5' for manufacturer B), so when checking the data content, each company can You don't have to understand the different data structures of umati, you can understand the information if you know umati.

Below is an image.

In addition, umati uses OPC UA as a communication protocol, which is also convenient and expandable, and enables safe communication with security in mind. We believe that umati, which adopts OPC UA, which is often treated as a protocol standard not only for machine tools but also in the industrial world, has many advantages compared to other protocols.

umati exhibition at the EMO venue

So how was umati actually realized at the EMO venue?

At this EMO, I don't think there were many manufacturers implementing umati on their CNCs. In most cases, manufacturers collected data from machine tools once and implemented umati along with an OPC UA server on the collected PC, or used an external gateway like the one below.

In the second EMO blog, I introduced automation and optimization using AI as the second overall technology trend, but in order to realize this, data from multiple machines is essential. . The exhibition made me keenly aware that the common data model, including umati, underpins this.

What about edge processing?

In addition to umati, there are companies introducing products that can be easily connected to AWS and Azure, and I feel that the number of ways to handle data in the cloud is increasing considerably.

In Japan, there are many people who dislike handling data in the cloud, so I wanted to know how European manufacturing companies think about managing data that will increase in the cloud and IoT, so I asked the EMO venue staff. Saw!

Even in Europe, data that cannot be stored in the cloud is sometimes handled on-premises. It was said that it was in the flow.

Also, rather than using the cloud as a platform for storing/analyzing data, there were also cases where the cloud was used as a platform for managing edge computers.

The Siemens SINUMERIK EDGE shown in the photo above not only collects data, but it is also possible to download data processing applications from the IoT platform MindSphere and perform data processing on SINUMERIK EDGE. increase. In addition to storing data in this way, it seems that the use of the cloud will expand to complement the functions of edge computing terminals.

There were also many exhibits of data collection using analog sensors, which Macnica is also focusing on, as part of edge processing.

What impressed me was that there were many products with built-in sensors in tool chucks and tool holders, mainly from European manufacturers. It can be said that it is a product specialized in acquiring data on the state during processing at a closer location. In particular, the feature of these products is that data visualization and data utilization are combined into one application, so it is easy to imagine how to use it, and it is expected to spread in the future.

The other is a product in which a sensor is embedded in a bearing or ball screw. I was able to see these products not only from manufacturers in Europe and Japan, but also from manufacturers in Asia such as Taiwan.

Personally, I was surprised by the lack of introductions of systems that utilize analog sensors from German and other overseas machine tool manufacturers. As mentioned above, the market as a whole has seen an increase in the number of various products, and they are gradually becoming more user-friendly. Will development proceed hand in hand with the manufacturer? I imagined.

lastly

I've told you what I saw and thought at EMO 2019 over the course of three installments. How was it?

I would appreciate it if you could taste the realism of Hannover.

From now on, I would like to devote myself every day so that I can convey the latest information that I thought was interesting and interesting related to the machine tool industry and AI / IoT.

Well then!