Improve operations by automating construction and heavy machinery

In Japan, labor shortages have become a problem in many industries and industries. Over the past few years, there has been strong demand in the construction industry, partly due to special demand. Solid demand is expected in the future for redevelopment and infrastructure development in the Tokyo metropolitan area. On the other hand, the construction industry is highly dependent on people, and the labor shortage is even more serious. Improving operations by promoting DX and automating construction and heavy machinery is an urgent issue.

Challenges of Autonomous Construction Machinery and Heavy Machinery

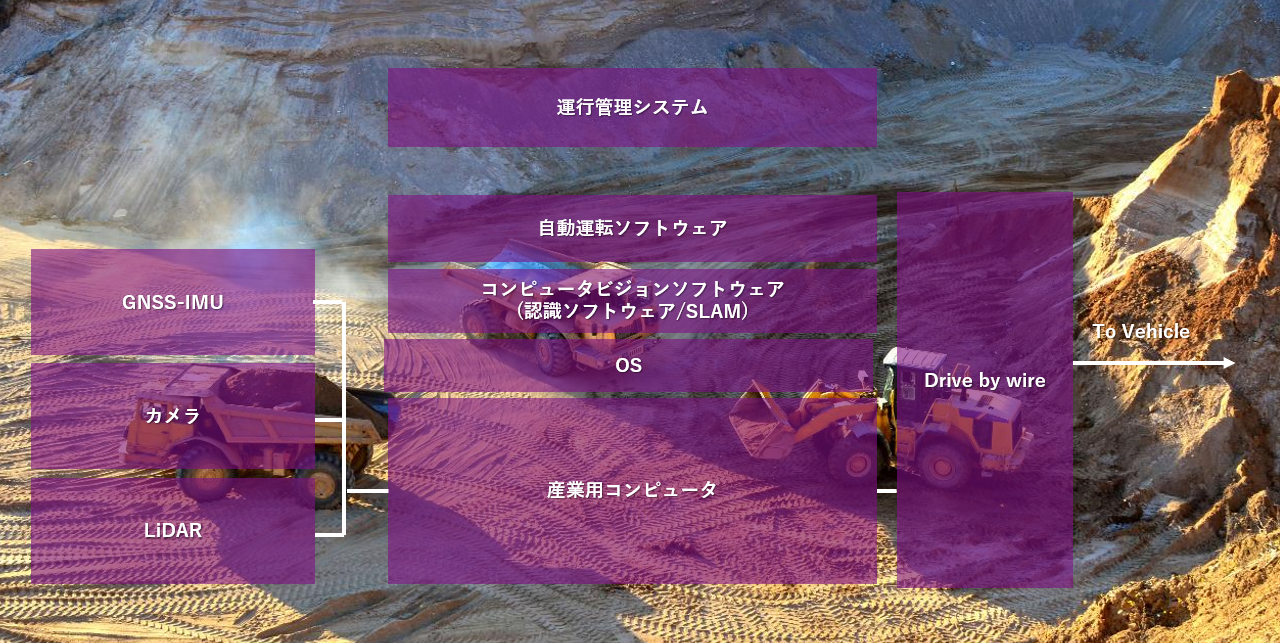

In general, vehicle autonomy requires many different technical elements. Various algorithms detect objects and recognize the surrounding environment using data obtained from multiple different sensors such as LiDAR and cameras. In addition, it understands its own position from HD map information, sensors and inertial devices, and autonomous driving software considers route planning and arm/cargo platform behavior.

The drive-by-wire control unit will give instructions to each module and ECU, and the implementation of actuators will operate each operation unit of the vehicle.

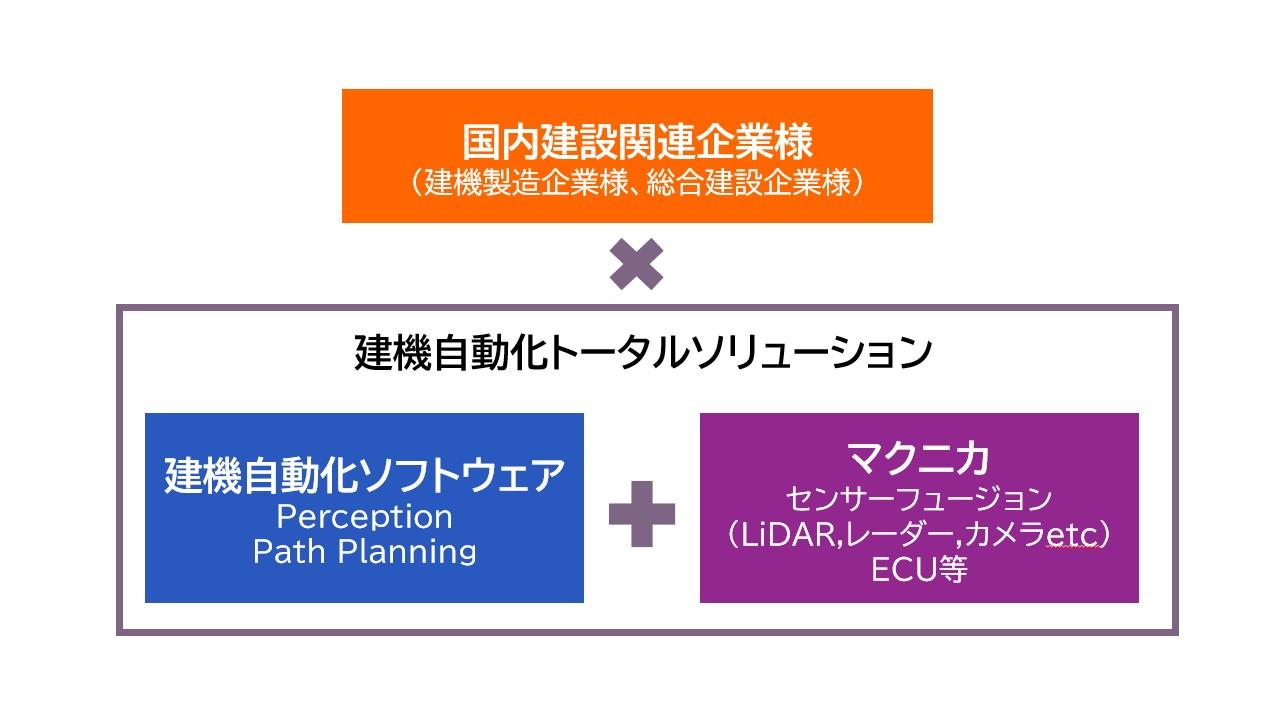

Various specialized vehicles are in operation at construction sites, depending on the type of work. There are various manufacturers of construction machinery and heavy machinery, and vehicle drive and control methods are complex. Therefore, there is no autonomy module that can be used universally. In addition, construction sites and mines where vehicles are used are often in environments where it is difficult for the on-board electronic components and autonomous driving software to recognize the surrounding environment, such as road surface conditions, the surrounding environment, and even dust. Although there is a demand for this, it is a background that makes it difficult to introduce it.

Framework for building autonomous systems

The environments in which our customers are using autonomous vehicles are varied and very different from typical public roads. In addition, since different types of work vehicles work in cooperation, there are a wide variety of combinations of vehicles, and it is necessary to consider special algorithms.

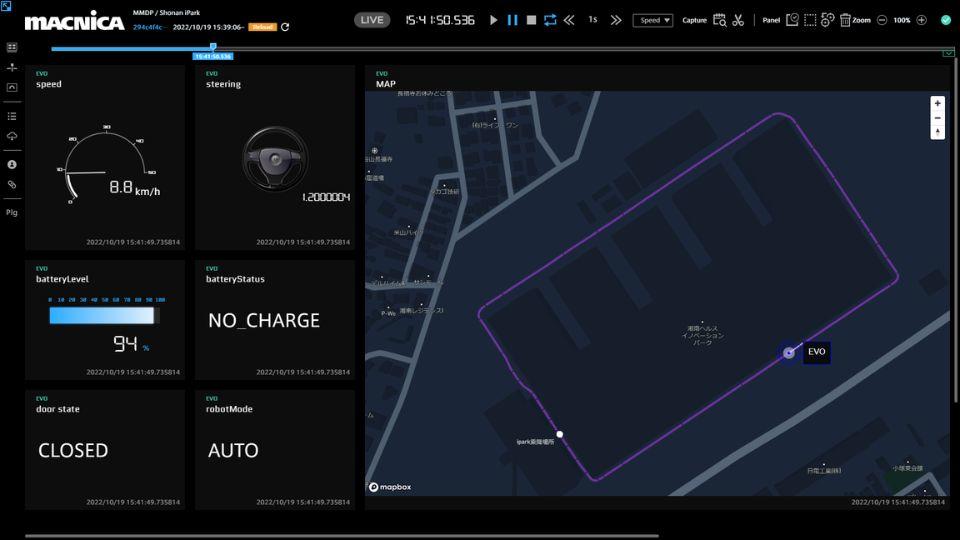

Management by vehicle operation management system (FMS)

A Fleet Management System is necessary for the effective use of autonomous driving vehicles. In particular, in order to effectively utilize multiple vehicles, integrated vehicle management by a control center is required.

Macnica provides a data platform for visualization, cloud services for easy-to-use dashboards, edge computers and unique communication protocols to reliably send vehicle data to the cloud. Very effective. Macnica performs technology fitting and proposes optimal solutions according to the customer's usage of construction and heavy machinery.

Related Technology Partners

Inquiry

If you have any questions about improving construction operations, please feel free to contact us.