モビリティ自律化ソリューション

技術の進化に伴い、製造現場や物流拠点、プラントなどでの機械化や自動化が進み、各工程内の生産効率は日々改善されています。しかしながら生産に必要な部材の運搬や完成した製品や商品の搬送などの運搬の効率化は、いまだ課題になっています。運搬が必要なモノはサイズや重量などが多岐にわたる事や、生産ラインのレイアウト変更、異なる車両との連携など、輸送手段や輸送ルートを柔軟に対応する必要があります。そのため、お客様のご用途や環境に応じた自動搬送ソリューションの構築支援を提供します。

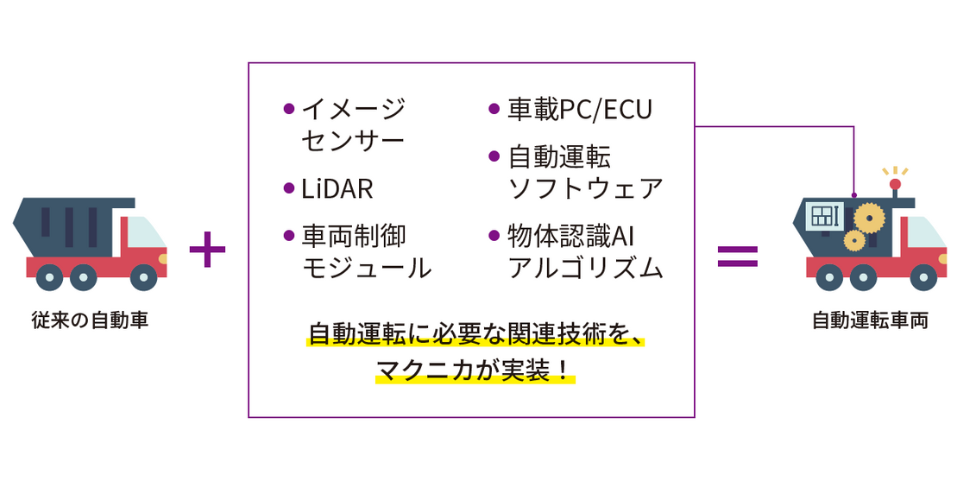

自律型車両構築インテグレーションサービス

物流が必要とされるロケーションや用途によって、自動走行に適した車両やセンサー構成、自動運転アルゴリズムなどが異なります。マクニカのエンジニアリングチームがお客様のユースケースに合わせ、最適なシステム構成を提案並びに車両構築の支援を行います。

自動走行トーイングトラクター

工場や空港など、比較的重量があるマテリアルや貨物の搬送では、トーイングトラクターが活用されています。構内のトーイングトラクターは、走行ルートが定められていることが多く、貨物のローディングの場所も比較的決まっている場所であることも多く、自律化システムが効果的に活用できるユースケースになります。弊社パートナーが提供する自動トーイングトラクターは、最大25tの牽引力を有し、最高速度(自動運転時)20km/Hで走行が可能です。

インフラ制御型車両搬送システム

日本国内では、一日に約4万台の車両が生産されています。生産された車両は、出荷までの間モータープールに置かれます。一般に完成車の検査終了後、所定の場所まで移動スタッフが実車を運転し、車両を移動させています。各工場の規模にもよりますが、多くの移動スタッフが人海戦術で行っているため、ここに効率化が求めらえる要因の一つになっています。Seoul Robotics社が提供するインフラ制御型車両搬送システムである”Control Tower”は車両側に特別な装置を設置することなく、工場のインフラ側より車両を制御を行い、所定の場所まで走行させるシステムです。

モータープール作業効率化

車両のモータープールまでの輸送は、ドライバーが行うのが一般的です。ある自動車メーカーでの輸送距離は約1km、1人のドライバーが80-100台/日の車両を移動させています。当然のことながら、ドライバーは完成車両をモータープールに移動させた後、次の車両を輸送する為に自動車の最終試験場に戻りますが、その際にドライバー移動専用の車両を使っています。この車両を自律化させることにより車両輸送現場での効率化が実現できます。

解説ムービー

お問い合わせ

自動運転物流支援サービスに関するご相談などございましたら、こちらよりお気軽にお問い合わせ下さい。