Finished car logistics

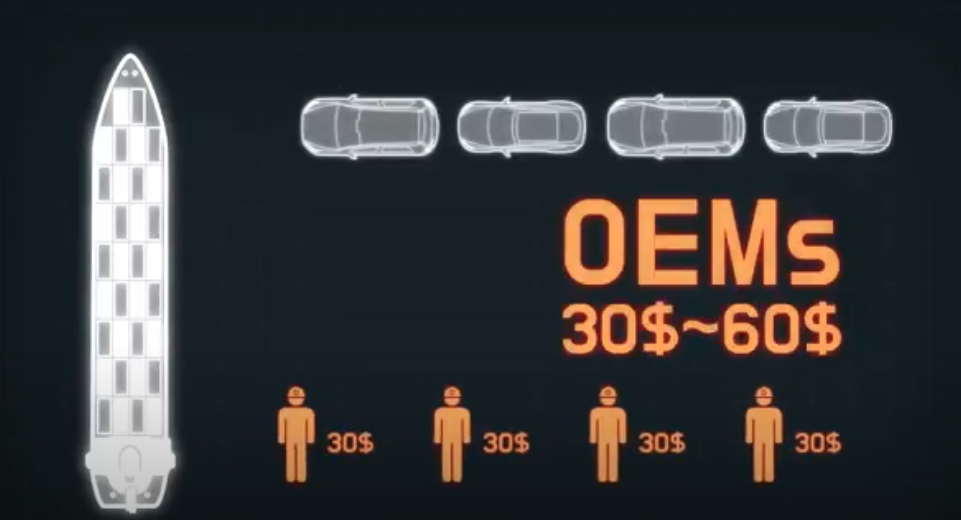

The last few years have seen technological advancements in the automotive industry, from electric vehicles and fuel efficiency to long-distance automation. However, the logistics of finished vehicles has become an area where advanced technologies, including autonomous driving, have not been fully utilized. Complete vehicle and supply chain logistics, on the other hand, account for 3-5% of assembly costs. The labor costs associated with this logistics cost an automaker (OEM) an average of $30 to $60 for each vehicle moved, so there is a solution to solve these challenges. I think it is necessary.

Why do we need new solutions?

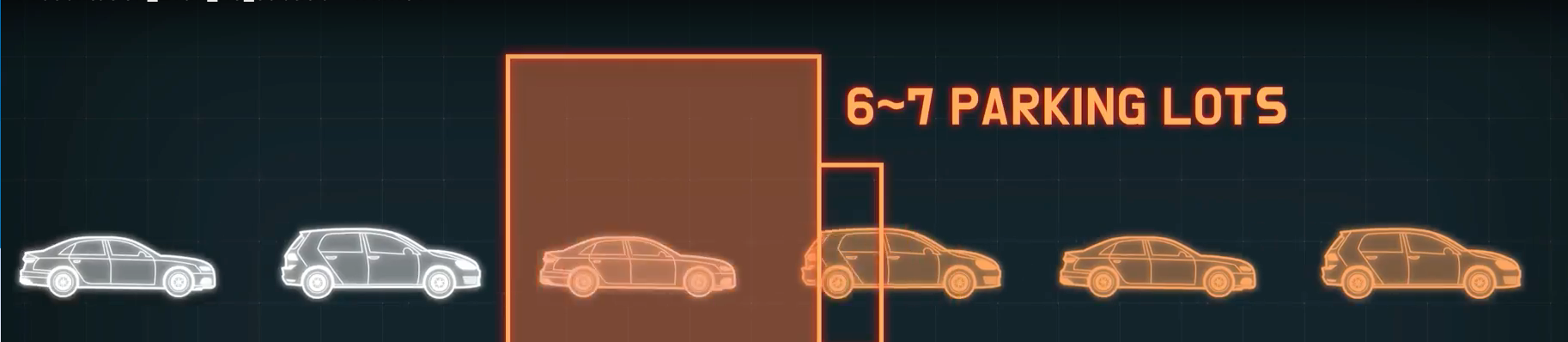

autonomous driving faces many obstacles. The cost is quite high, the safety has not been verified, and the processing power is insufficient. Currently, vehicles cannot fully recognize and predict obstacles, and communication between vehicles is often incomplete. OEMs spend billions of dollars each year on the logistics of finished vehicles, moving vehicles from the production line to intermediate parking lots and then on ships, trains and trucks to their final destination, the dealership. On average, a vehicle travels to 6-7 parking lots from the assembly line to the final customer. Each time the vehicle is moved, a person will personally enter the vehicle and drive it within the lot. Smart, automated solutions reduce labor costs in complete vehicle logistics, reduce vehicle damage, and ensure employee safety.

How does it work?

Together with our partner Seoul Robotics, Macnica is taking an innovative approach to bring automation to finished vehicle logistics. This is called Level 5 Control Tower (LV5 CTRL TWR), and the technology used to configure the system is explained below.

Infrastructure-based cognitive system

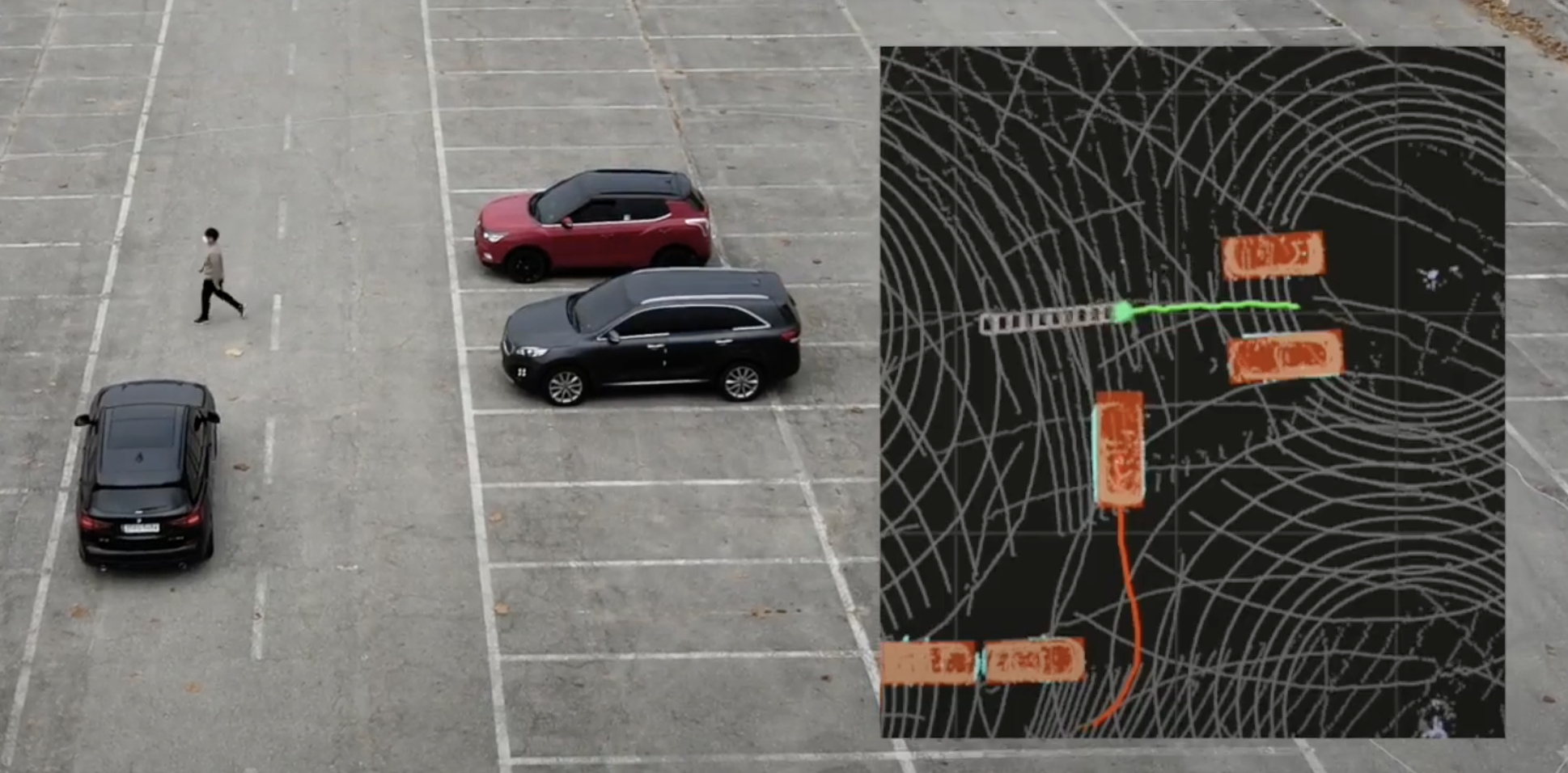

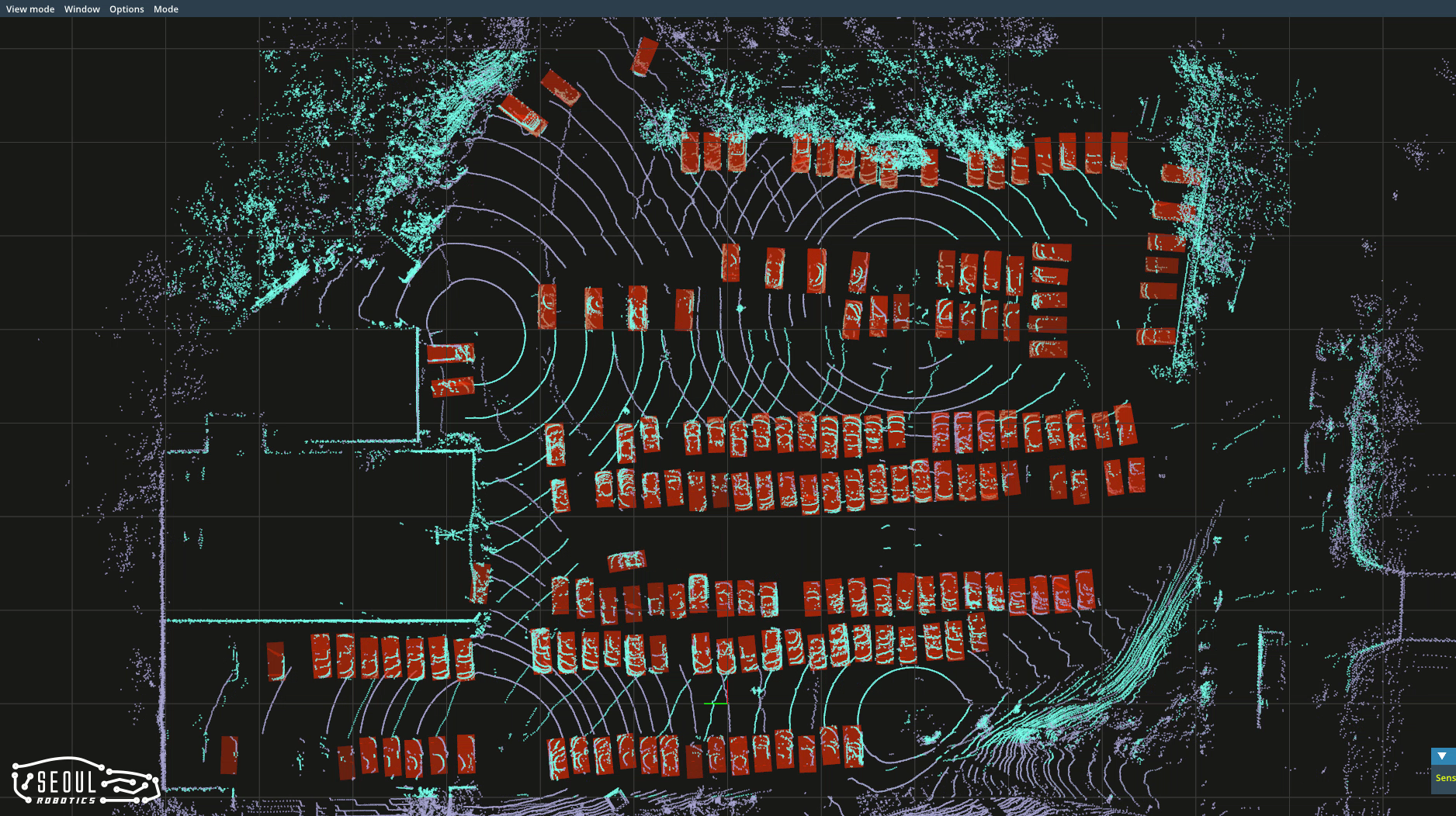

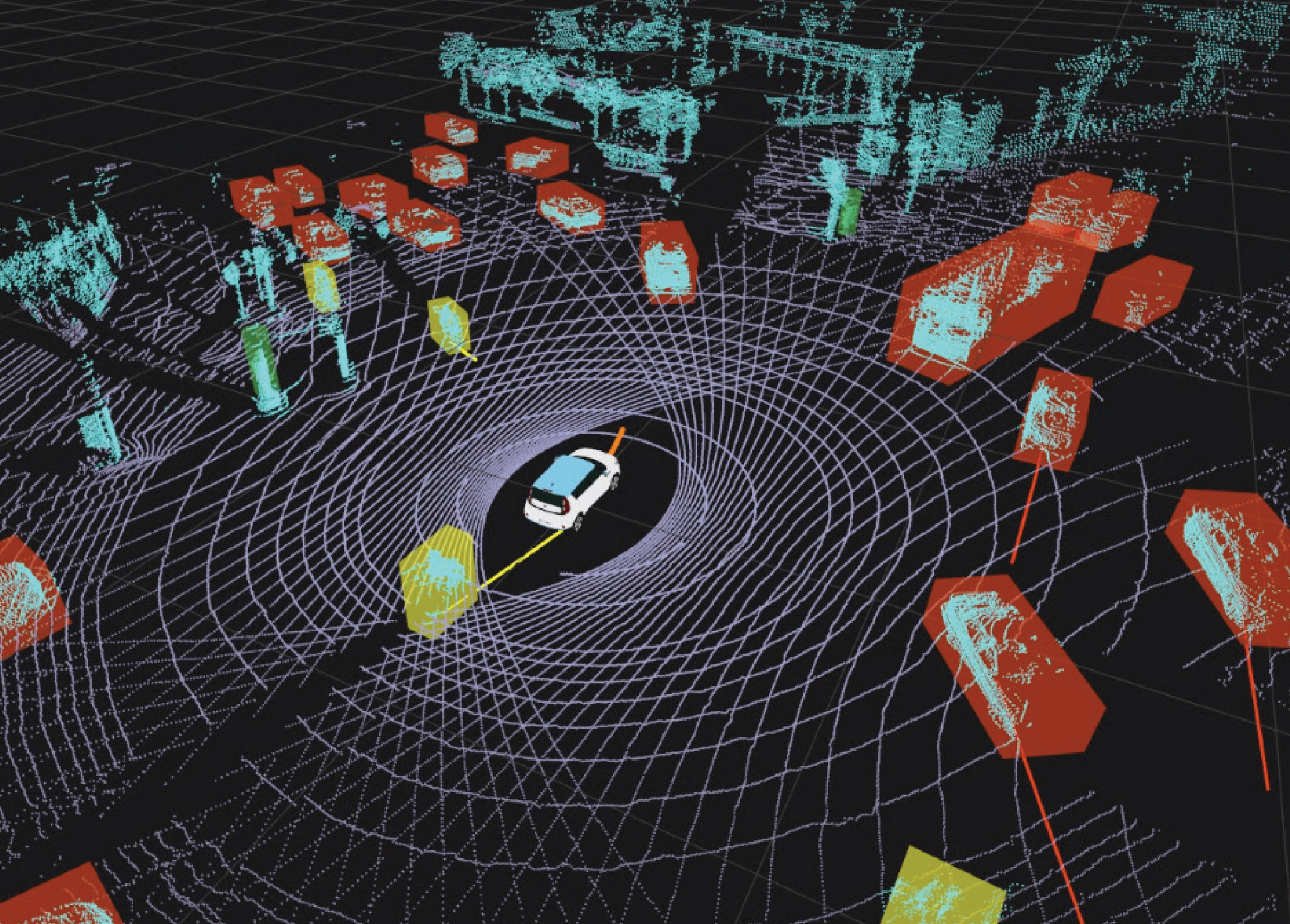

This breakthrough technology guides vehicles from the surrounding infrastructure rather than individual autonomous driving cars with sensors, computers and software. 3D sensors are installed in the facility, always with at least two sensors to improve the detection accuracy. This detection redundancy minimizes blind spots for vehicles.

Cloud

Determine a safe route for each autonomous driving car from origin to destination via the cloud. LV5 CTRL TWR can detect, classify and track other vehicles and pedestrians and even predict their movements. The system updates every 0.1 seconds and determines vehicle position with 99.9% accuracy (up to 4cm error).

wireless control

The LV5 CTRL TWR can use the local 5G or 4G networks that are standard in today's cars, or other low-latency V2X systems, to remotely autonomous driving vehicles. The system sends encrypted control commands to designated vehicles to achieve vehicle automation. By using these technologies, thousands of non-autonomous driving vehicles can be autonomous driving autonomously as long as they are connected to the LV5 CTRL TWR grid.

Powered by 3D Perception

The LV5 CTRL TWR is powered by Seoul Robotics' powerful cognitive platform, SENSR. SENSR is a 3D vision platform for LiDAR and 3D sensors that is extremely robust and accurate. SENSR can simultaneously fuse, coordinate and process data from hundreds of sensors based on deep learning AI (artificial intelligence) in real time, so all vehicles and people within the application area of LV5 CTRL TWR , can provide specific location information for other physical entities.

Key Features/Benefits

safety

By placing multiple sensors in the infrastructure, the system is able to minimize blind spots for all vehicles. This leads to fewer accidents and less damage to the vehicle. It also provides employees with a safer environment. In addition, it has multiple fail-safe systems in software and hardware.

operational efficiency

LV5 CTRL TWR enables an organization to streamline complex logistics operations by optimizing processes, people and technology to achieve improved outcomes. autonomous driving car capabilities enable 24/7 logistics operations, allowing thousands of vehicles to move simultaneously without human intervention. It is possible to redesign the entire factory for maximum efficiency and improve space utilization by 20%.

cost savings

Investing in LV5 CTRL TWR technology is important to improve production costs and increase overall profitability. OEMs can reduce logistics costs for complete vehicles by more than 70%. No vehicle retrofit is required as the technology is implemented in the infrastructure. OEMs can expect return on investment (ROI) within two years.

Outlook

The LV5 CTRL TWR has great potential to autonomous driving mobility beyond the logistics of finished vehicles, and to transform its operations in a wide range of applications, including commercial and public logistics.

• Vehicle distribution center

• Car rental company

• Used car auction house

• Automated Valet Parking (AVP)

• Public transport

• Track automation

• Forklift automation

• Warehouse and robot automation

About Seoul Robotics

Founded in 2017, Seoul Robotics is a company that uses deep learning AI to provide 3D perception solutions that expand the future of mobility. The company's 3D Perception Platform creates real-time, accurate 3D models of the world, demonstrating its unrivaled ability to detect, classify and track 4-wheelers, 2-wheelers (motorbikes/bicycles) and pedestrians. To do. This patented technology understands 3D data to increase accuracy and efficiency while still ensuring safety. It is used in various industries and applications such as autonomous driving, smart city, smart factory, security, ITS (intelligent transportation system), retail stores, venues, etc. The company's software platform is compatible with virtually all LiDAR and 3D sensors on the market, regardless of sensor type.

We will introduce other development support services that we provide using software from Seoul Robotics.

Inquiry

Please feel free to contact us for any questions or consultations.