マクニカ、製造現場の生産性向上をAIで実現!映像からヒューマンエラーを即座に自動判定するRetrocausal社の「Pathfinder」を提供開始~作業ミスの流出を未然に防ぐことで生産性の向上に貢献~

Macnica, Inc. (headquarters: Yokohama, Kanagawa Prefecture; Representative Director and President: Kazumasa Hara; hereinafter Macnica"), a total service and solutions provider in semiconductors, networks, cybersecurity, and AI/IoT, is pleased to announce that it has signed a reseller agreement with Retrocausal, Inc. (headquarters: Redmond, Washington, USA; CEO: Zeeshan Zia; hereinafter "Retrocausal") for Pathfinder (a tool for instantly and automatically identifying work errors). As a result, Macnica, as a strategic partner of Retrocausal, will begin selling the product in Japan to companies aiming for digital transformation.

In recent years, as labor shortages and succession problems for veteran workers have been pointed out, factories and other production sites are shifting to factory automation, and robots and sensors are beginning to be used in the production process. However, manual work by humans is still required in factories, especially in the assembly process, and it is necessary to reduce human error in that work.

On the other hand, in a factory, it is necessary to proceed with work according to a certain procedure according to the manual. For example, in order to prevent the outflow of defective products due to human error, such as making a mistake in a task or skipping a step, the reality is that many factories carry out pre-shipment inspections that are more thorough than necessary. is.

Real-time detection of human error during work is necessary to reduce the burden on the manufacturing floor, including such inspections, and to improve quality and efficiency.

Therefore, Macnica, which has been supporting Digital Manufacturing, will now start handling Retrocausal's Pathfinder (an instant automatic detection tool for work errors).

Since 2019, Retrocausal has been providing specialized support to the manufacturing industry, contributing to improving productivity by preventing work errors from occurring. Based on this knowledge, we use a unique patented AI algorithm and a highly usable UI to analyze worker movements in the manufacturing process and provide highly accurate models and UIs, allowing anyone to work on improving the workplace. We support the construction of

■ Use case

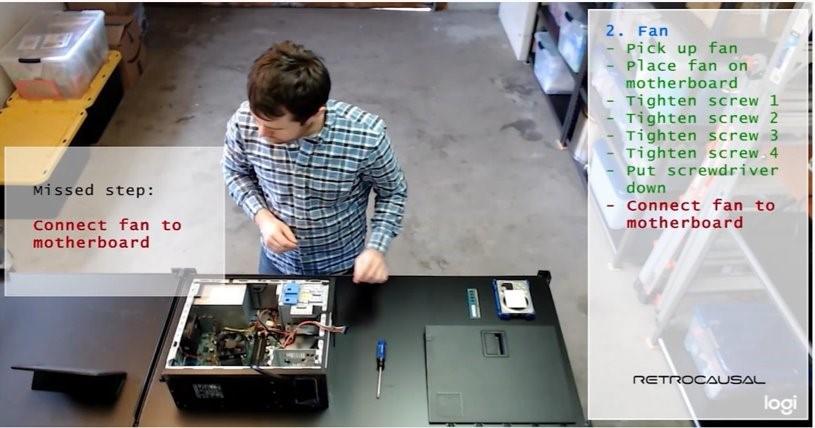

Let's take the process of assembling a desktop computer as an example.

We will install the CPU, fan, RAM, etc. in order, but if you forget to "connect the power cable" that should be done at the end of installing the fan, when the worker tries to start installing the next RAM, Pathfinder will automatically detect and issue an alert (see below). By pointing out the human error that occurred in this way, the work can be corrected immediately. In addition, this will not only prevent the outflow of work mistakes, but also improve the proficiency of workers, which will lead to improvements in future human errors.

Blue ⇒ Current process / Green ⇒ Work completed / Red ⇒ Omission, work mistake

In the future, Macnica will continue to support the development of DX human resources and the acceleration of operational efficiency in order to promote DX in various industries in addition to the manufacturing industry.

*Company names and product names mentioned in this text are trademarks or registered trademarks of Macnica and each company.

*The information published in the news release (including product price, specifications, etc.) is current as of the date of announcement. Please note that the information may be subject to change without prior notice.

About Retrocausal, Inc.

Retrocausal provides solutions that help manufacturing workers avoid assembly errors, better train them and improve processes, trusted by the most prominent manufacturers in the US, Japan and South America. Solution provider.

Retrocausal's Pathfinder platform uses AI to analyze work on a manufacturer's assembly line in real time, providing audio and visual alerts when mistakes occur, ensuring workers Allow assembly to complete. In addition, the Pathfinder platform will continuously time-study the assembly process to help companies accelerate Kaizen events.

About Macnica

Since its establishment in 1972, Macnica has provided cutting-edge semiconductors, electronic devices, networks, and cybersecurity products with added technological value. Based on our traditional strengths of global cutting-edge technology sourcing and technology planning capabilities, we are developing new businesses in fields such as AI/IoT, autonomous driving, and robots. Under the slogan "Co. Tomorrowing," we will connect cutting-edge technology and Macnica 's intelligence to provide unique services and solutions, creating social value and contributing to the development of future society. the Company company is headquartered in Yokohama and operates global business with 85 locations in 23 countries around the world. Please see the website (https://www.macnica.co.jp) for details.

Inquiries from the press regarding this matter

株式会社マクニカ https://www.macnica.co.jp

コーポレートマーケティング部 広報室 宮原 e-Mail:macpr@macnica.co.jp

〒222-8561 横浜市港北区新横浜1-6-3 マクニカ第1ビル