Macnica (headquarters: Yokohama, Kanagawa Prefecture; Representative Director and President: Kazumasa Hara; hereinafter referred to as Macnica), a total service and solutions provider in semiconductors, networks, cybersecurity, and AI/IoT, has jointly developed an IoT infrastructure platform with Toyo Shinyaku Co., Ltd. (headquarters: Fukuoka City, Fukuoka Prefecture; President and Representative Director and President: Hattori Toshimitsu; hereinafter referred to as Toyo Shinyaku), a manufacturer of health foods and cosmetics, that can visualize and analyze the production status of the entire factory of the company's Intelligence Park (manufacturing health foods; hereinafter referred to as IP) in real time.

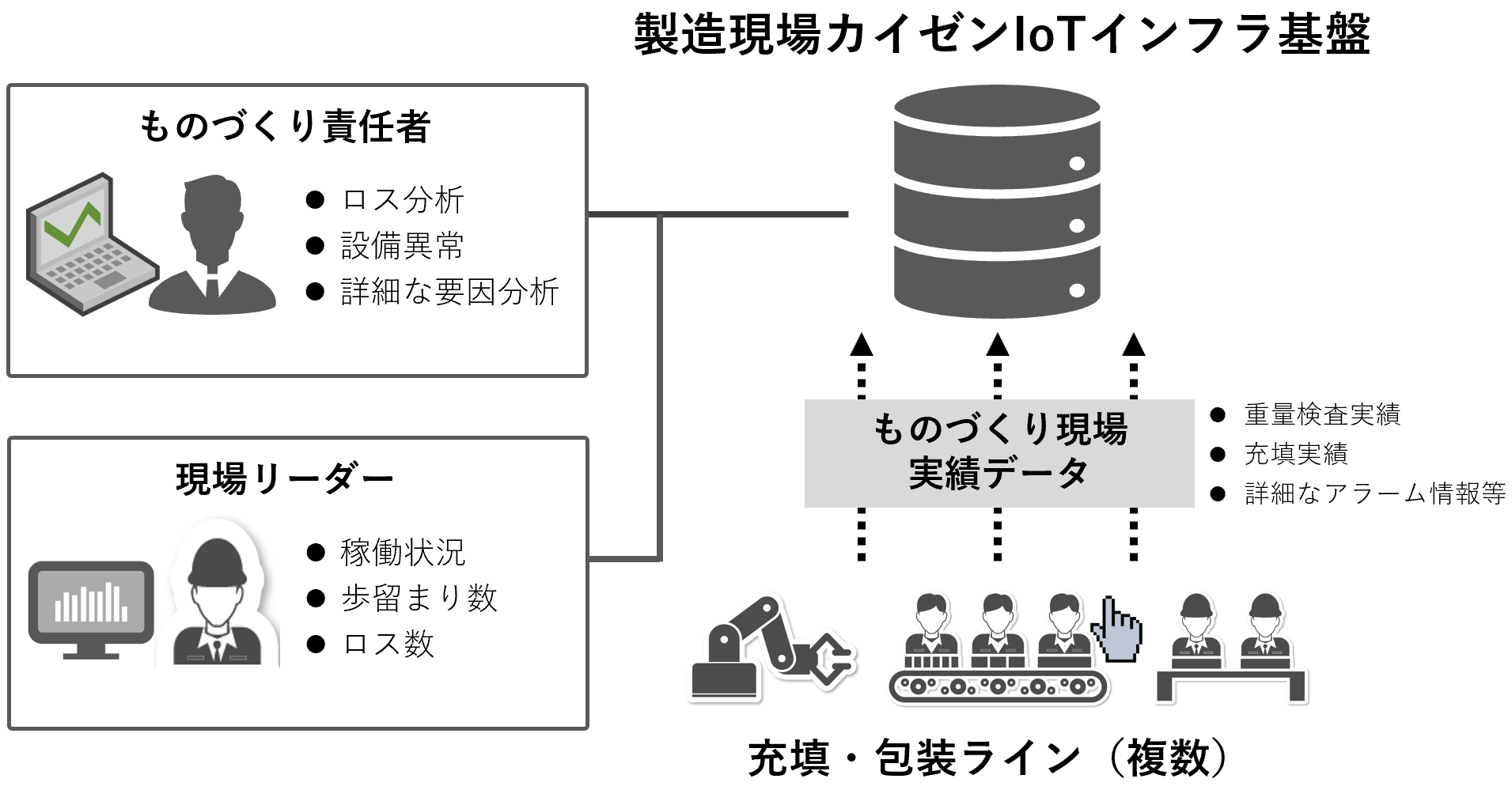

The IoT infrastructure developed this time utilizes the factory visualization solution provided by the Company, collects and processes the production information and equipment information of the Toyo Shinyaku IP, and remotely grasps the production status of the entire factory in real time. It is possible to analyze and quickly respond to equipment abnormalities and quality defect prevention.

■ Background

At Toyo Shinyaku, as a comprehensive contract manufacturer that can manufacture both "health foods" and "cosmetics" on a one-stop basis, we use our unique business model of "ODEM", which is both ODM and OEM, as a weapon, from product planning to prescription. We provide total support from design, manufacturing to sales promotion support. In 2019, we installed a new IP as a next-generation manufacturing base, and while promoting DX company-wide, we started working on a smart factory as a measure to "maximize the efficiency of equipment operation." Under such circumstances, the real-time visualization of the site by utilizing information has become a chronic issue. Although we managed the progress of the production line using Excel, we had to collect and analyze the data ourselves. In the company, which promotes business centered on ODEM, which is made-to-order, the company itself will not function unless data flows all the way from sales to manufacturing. Aiming to create an environment where it is possible, we have started joint development efforts for an IoT infrastructure that realizes real-time visualization of IP and remote factory management.

■Overview of IoT infrastructure

Through this joint development with Macnica, Toyo Shinyaku will be able to improve the results of post-packaging weight inspections, filling results from filling machines, and equipment installed on the line that fills and boxes products such as health foods. A variety of on-site information, including detailed alarm information, was collected into the master PLC, aggregated on the IoT infrastructure, and visualized using BI tools. In addition, information such as the number of yields such as the number of products rejected by inspection and the number of losses such as defective packaging boxes can be shared on the spot.In the past, data was aggregated in Excel after the day's work was completed. However, it is now possible to check progress in real time. Additionally, since it is possible to drill down and view detailed information from the operating status displayed in the BI tool, it is now possible to expand the scope of utilization by analyzing this data.

■ About the future

Toyo Shinyaku has taken the first step toward a smart factory by utilizing this IoT infrastructure. In the future, we will aim to integrate all information from sales to logistics by linking with the core system. In particular, we plan to take steps toward a smart factory while incorporating new ideas such as preventive maintenance for equipment maintenance and calculation of standard man-hours through flow line analysis.

Mr. Moriyama, who was deputy IP plant manager at Toyo Shinyaku at the time, said, "Because Macnica has a long track record and deep knowledge, we would like them to introduce us to the best examples that will be useful to us and to cooperate with us more proactively through proposals than ever before. We would also like them to continue to work hard to create an easy-to-understand environment on-site, such as by making proposals after clarifying the reasons for the operations."

Macnica will continue to work with Toyo Shinyaku under the mission of Digital Synergy Factory, a manufacturing DX support brand, "We will work with our customers to solve all their management issues and digitize their manufacturing sites. Together we will draw up a grand design and accelerate business transformation." We will support DX in.

■ Related links

・Digital Synergy Factory (https://www.macnica.co.jp/business/ai_iot/)

*Company names and product names mentioned in this text are trademarks or registered trademarks of Macnica and each company.

*The information published in the news release (including product price, specifications, etc.) is current as of the date of announcement. Please note that the information may be subject to change without prior notice.

About Toyo Shinyaku Co., Ltd.

Founded in 1997, Toyo Shinyaku is a general contract manufacturer of health foods and cosmetics. We are building a new business model called “ODEM” based on both ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing). We provide speedy response to various customer requests with total support, from consulting on all aspects of business, to product planning, product design, formulation development, manufacturing, delivery, and sales promotion support. Our research and development department has a system that enables us to search for functional ingredients, conduct tests on efficacy and safety, and conduct clinical trials. We have a wealth of reporting experience. In addition, the manufacturing plant complies with cGMP (U.S. GMP for proper management of the manufacturing, packaging, labeling, and storage of dietary supplements) for the first time as a domestic comprehensive contract manufacturer. We have acquired various certifications and certifications such as FSSC22000 and ISO22716, and have built a quality control system that meets international standards. For details, please see the website (https://www.toyoshinyaku.co.jp).

About Macnica

Since its establishment in 1972, Macnica has provided cutting-edge semiconductors, electronic devices, networks, and cybersecurity products with added technological value. Based on our traditional strengths of global cutting-edge technology sourcing and technology planning capabilities, we are developing new businesses in fields such as AI/IoT, autonomous driving, and robots. Under the slogan "Co. Tomorrowing," we will connect cutting-edge technology and Macnica 's intelligence to provide unique services and solutions, creating social value and contributing to the development of future society. the Company company is headquartered in Yokohama and operates global business with 85 locations in 23 countries around the world. Please see the website (https://www.macnica.co.jp) for details.

Inquiries from the press regarding this matter

株式会社マクニカ https://www.macnica.co.jp

コーポレートマーケティング統括部 広報室 宮原 e-Mail:macpr@macnica.co.jp

〒222-8561 横浜市港北区新横浜1-6-3 マクニカ第1ビル