Overview

High-frequency switches using wide bandgap semiconductors contribute to the efficiency of power conversion. Silicon carbide switches, for example, can be implemented as SiC MOSFETs or as SiC FETs in a cascode configuration.

This article traces the origins of SiC FETs, their evolution to the latest generation, and compares their performance with other technologies. In four installments, I will discuss the differences in physical characteristics, approaches and features for ideal switches, reliability, and unique uses in real-world applications.

To prove the reliability of SiC FETs

In addition to the high temperature and high voltage resistance of wide bandgap switches, the advantage of SiC FETs is that they do not use a SiC gate oxide film, unlike SiC MOSFETs, which are subject to deterioration due to high electron beams. Cascode's Si-MOSFETs are rugged low-voltage types with high threshold voltages, thick gate oxides, and are protected by internal Zener clamps. In fact, SiC FETs are so reliable that they now routinely achieve automotive AEC-Q ratings. The key is reliability under unintended stresses such as overvoltages and short circuits. SiC FETs have robust avalanche behavior that is activated by breaking the drain-gate of the JFET.

As a result, the current flowing through Rg in Figure 2, "Approaches and Features for the Ideal Switch" reduces the voltage, turning on the JFET and clamping the overvoltage. Si MOSFETs thus avalanche, but are highly controlled and consume very little power because avalanche protection diodes are included in the fabrication of each cell. SiC MOSFETs also have avalanche ratings, but GaN HEMT cells do not, requiring manufacturers to evaluate their parts at lower voltages to ensure sufficient margin between working and breakdown voltages.

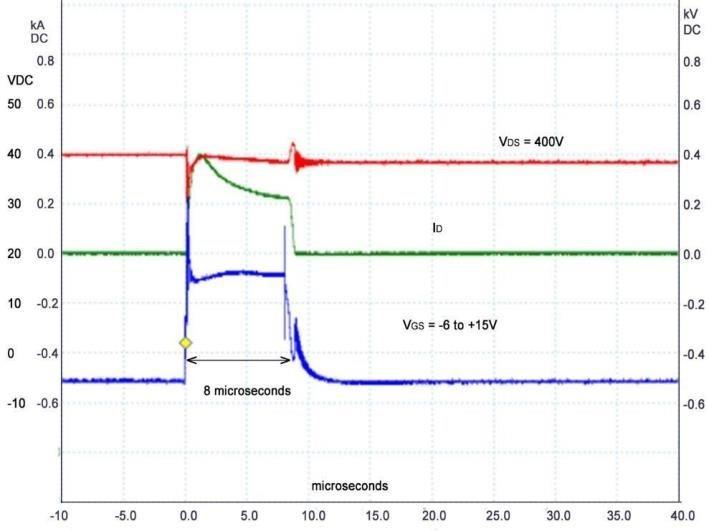

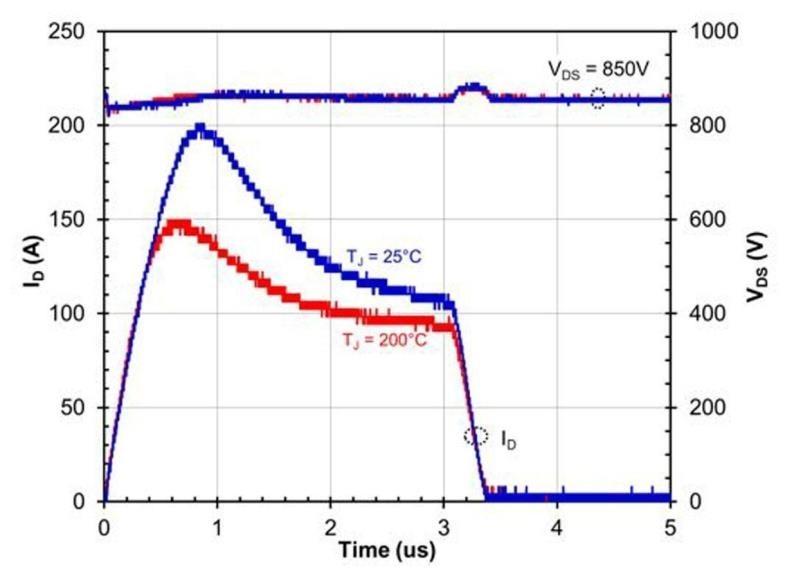

SiC FETs also have moderate short-circuit current characteristics. At high currents, the slope of the voltage drop across the channel limits the current with a natural "pinch-off" effect. The short-circuit current does not depend on the gate voltage, unlike MOSFETs and IGBTs, and the positive temperature coefficient of the on-resistance of the channel of SiC FETs also reduces the limiting current and distributes the stress to individual cells within the die. Helpful. This effect is so stable that SiC FETs can be used as precise current-limiting devices in linear circuits. Figure 1 shows that the 750V SiC FET survived the 8µs stress without degradation. Figure 2 shows the effect of a 1200V rated SiC FET on increasing on-resistance with temperature and reducing the short-circuit current to a final value that is almost independent of the initial junction temperature.

Packaged SiC FETs must minimize temperature rises and gradients to maintain reliability, but SiC's strength lies in its thermal conductivity, which is more than three times that of silicon and GaN. . The latest devices also use sintered silver instead of solder to attach the die, improving interface thermal conductivity by a factor of six, resulting in lower junction temperature rise and higher reliability. can keep.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.