"Motors" are used in a variety of applications, and there are many types of them.

This time, we will introduce the contents of a demonstration video that compares the five specifications required for motors used in high-voltage water pumps between AC motors and brushless DC motors (BLDC motors).

The demo uses motor drivers and reference designs from Texas Instruments (hereafter TI), and there is also a product introduction at the end, so please take a look.

Water pump demonstration video using AC motor/BLDC motor

Video flow

0:00 - 1:06 Water pump demo configuration

- Lower left: AC motor, Lower right: BLDC motor

The water pumped up by the two motors at the same time passes through the left and right outer pipes and returns from the center pipe. - Top: The digital meter controls the flow rate of the assembled water, Bottom: The LCD panel controls the power consumption of the motor

- Devices used: AC induction motor (120V), BLDC motor, AC to DC Flyback converter, TIDA-01493

- By connecting an AC to DC converter on the BLDC motor side, 5 points can be compared using the same AC power supply.

1:06 - 2:48 Introduce 5 benefits of using BLDC motors

We have introduced in detail the points that you should keep in mind, so please take a look there.

Points to keep in mind

5 reasons why BLDC motors can be used, not just "driving large equipment = AC motors"

If you compare how an AC-DC converter works when pumping the same amount of water with the same AC voltage...

- 31% less power required

- 75% reduction in motor volume

- 13% less noise

- Wide range of AC input voltage available = Can be used in various countries and regions

- Speed control is possible = Can be used in various applications and situations

| Advantage | Item | ac motor | BLDC motor |

| 1 | electric power | 44.3W | 30.5W (31% power reduction compared to AC motors) |

| 2 | size | - | 1/4 the volume of AC motors |

| 3 | noise | 77db | 64db (13% noise reduction compared to AC motors) |

| 4 | AC input voltage/frequency Correspondence range |

Single AC voltage single frequency |

88 - 265 [V] 50 - 60 [Hz] |

| 5 | Speed control | Fixed | variable (223 gallons/min to 4 gallons/min) |

Target applications for BLDC motors

- Fans and ceiling fans

- air purifier and humidifier

- dryer circulation fan

- Drainage and water pumps

TI BLDC motor driver used in demo video

DRV10987

The DRV10987 is a three-phase sensorless 180° sinusoidal motor driver with integrated power MOSFETs capable of supplying up to 2A of continuous drive current.

The device is low noise and specifically designed for fan and pump applications with low external component count.

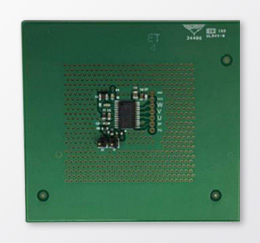

TIDA-01493

TIDA-01493 is a sensorless brushless DC (BLDC) motor driver reference board featuring the DRV10987.

Applications include dryer fans, drain pumps, and air purifiers. In these applications, the substrate is often covered with an encapsulant to protect the device from moisture. When the device temperature gets too high, the encapsulant can melt, so this reference design optimizes the heat dissipation of the DRV10987 so that it does not reach melting temperature.

This product is not for sale on the TI and Macnica-Mouser sites, but provides design data.

Contact Us

If you have any questions or would like to know more about the products introduced in this article, please contact us below.

Click here for recommended articles/materials

How to choose a TI motor driver / 5 recommended evaluation boards

Motor control using a microcomputer -Brushless DC motor control explained with video-

I tried to operate a brushless DC motor and encoder with Sitara AM437x

LAUNCHXL-F28027F realizes sensorless motor control in just 5 minutes