What is CBM (Condition Based Maintenance)?

CBM is an abbreviation of "Condition Based Maintenance", and is a concept of predictive maintenance that judges and implements the necessity of maintenance before failure by monitoring the condition of the target object. refers to

近年CBMは数多くの企業で取り組む最も大きな課題の一つです。

Efforts are particularly noticeable in the industrial machinery industry, where the opportunity loss in the event of a failure is large and the unit price is high, making it difficult to replace easily.

This time, we will introduce IMV's vibration pickup sensor VP8021-A, which plays an important role in realizing CBM.

Flow for realizing CBM

First, what kind of flow should be taken to realize CBM? The flow can be roughly divided into the following three categories.

-Sensing machine status

-Processing of sensing data

-Judgment of failure criteria based on processed data

The requirements definition for each flow differs depending on the target device. Among these, the flow that is particularly important and requires verification is generally referred to as "mechanical condition sensing."

This is because if the sensing data is wrong, the other two flows will be meaningless no matter how many times they are verified. The next section explores equipment state sensing in more detail.

Determination of sensing target

Now, the first thing that must be decided in sensing the device status is “what” should be the sensing target. There are many elements that can be sensed, such as vibration, current, and temperature, but the sensing target that is widely and commonly used in CBM is "vibration."

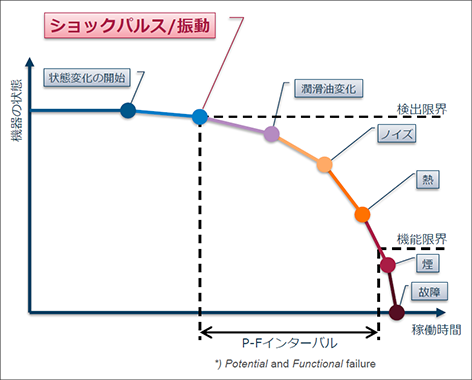

Here is a diagram showing the deterioration of the machine. Naturally, as time passes, the state of the machine changes.

Vibration is the first sign of deterioration on the curve from initial conditions to failure.

By measuring vibration, machine failures can be determined earlier.

To measure fault vibration

So what is mechanical vibration for measuring failures, and what kind of vibration sensor should be used?

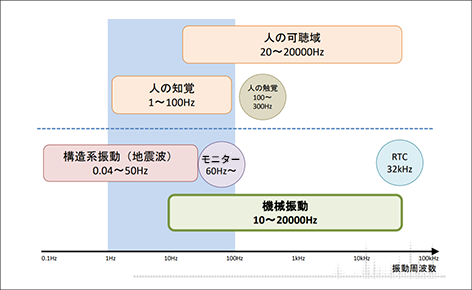

This figure summarizes the types of vibration for each frequency.

Mechanical vibration is generally said to be between 10Hz and 20,000Hz, and you can see that the frequency is many times higher than the vibrations we usually see.

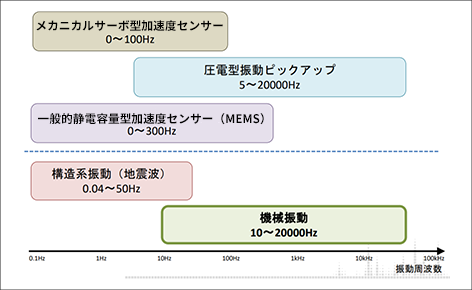

Vibration sensors commonly used to detect machine vibrations can be divided into the following three types.

-Mechanical servo type acceleration sensor

-General capacitive acceleration sensor (MEMS)

-Piezoelectric vibration pickup sensor

Among them, the sensor that can measure up to high frequencies is the piezoelectric vibration pickup sensor. However, many piezoelectric vibration pickup sensors are expensive, and some expensive ones cost more than 100,000 yen.

The capacitive vibration pickup sensor VP8021-A from IMV, which is introduced this time, can solve the biggest problem of piezoelectric sensors, which is "cost".

Now, let me introduce the details of the VP8021-A.

What is VP8021-A?

VP8021-A is a capacitive vibration pickup sensor. Inside the product, an inexpensive MEMS acceleration sensor "ADXL1002" provided by Analog Devices, which can measure even high-frequency vibration, is adopted.

-Click here for details on Analog Devices' "ADXL1002"

By using this sensor, it is possible to acquire vibration data similar to that of a conventional piezoelectric vibration pickup sensor while keeping costs down.

It can be purchased for 25,000 yen to 30,000 yen (*1) at the time of mass production, and the introduction itself can be inexpensive.

-*1: Prices are subject to consultation depending on the order quantity. Please use the contact button or contact a Macnica Ultima Company representative.

Main features of VP8021-A

The features of IMV's "VP8021-A" are introduced below.

|

IMV "VP8021-A" |

|

|---|---|

| Vibration frequency range | 10Hz to 10kHz |

| Output specification | IEPE output |

| Acceleration linearity | ±5% |

| noise density | 464 (um/s²)/√Hz |

| Temperature sensitivity error | ±3% |

| Operating temperature limit | -30℃~120℃ |

| size | 17mm x 27mm |

About data processing acquired by VP8021-A

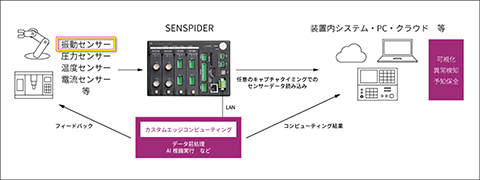

Since the data acquired by the VP8021-A is of high frequency, a processing terminal capable of AD conversion of signals of up to 10 kHz is required.

Macnica offers SENSPIDER, which can process high-frequency signals and implement AI to realize edge computing. For details, please check the official website here.

If you are considering CBM, but are worried about the cost, please contact us!

Vibration measurement demonstration video by VP8021A + SENSPIDER

So far in this volume, we have introduced the realization of CBM using vibration sensors.

Precise diagnosis can be easily performed by performing FFT analysis of vibration data from IMV's acceleration pickup sensor (VP8021-A) using SENSPIDER + Sigma.

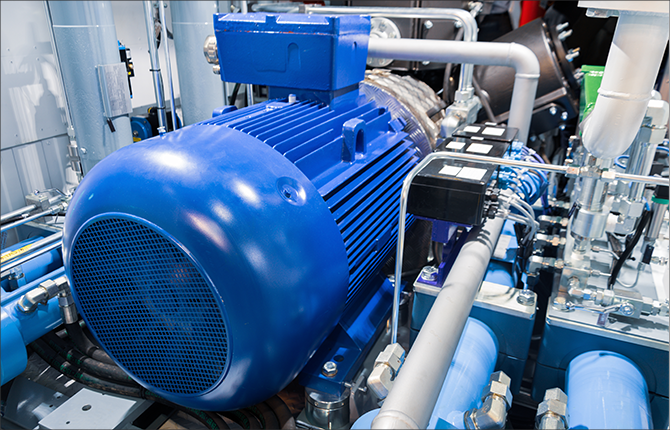

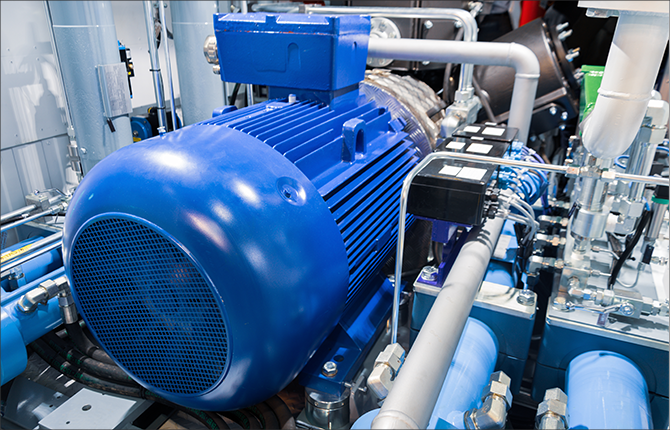

Application example

・Injection molding machine

·boiler

·mixer

·compressor

・Industrial equipment equipped with other motors and bearings

Click here for recommended articles/materials

Click here to purchase products

Click here for manufacturer site/other related links

Inquiry

If you have any questions regarding this article, please contact us below.

Analog Devices Manufacturer Information Top

If you want to return to Analog Devices Manufacturer Information Top, please click the button below.