Issues in corporate waste treatment and food residue

Waste reduction and recycling are important themes for a sustainable future.

In Japan, since the concept of 3Rs was introduced in 2000 under the Basic Law for Establishing a Recycling-Oriented Society, the separation, recycling, and reuse of garbage have become widespread, and local governments and companies are taking environmentally conscious measures into consideration.

Among wastes, food waste such as processing residue and cooking waste generated during food manufacturing and cooking processes has a high water content, so incineration not only reduces combustion efficiency but also releases large amounts of harmful CO2 and particulate matter. There are concerns about the generation of substances.

For these problems, food waste of dehydration significantly by Weight reduction do

"screw press dehydrator I would like to introduce you to ``.

Extremely effective in reducing food waste

The screw press dehydrator "DMseries" is the perfect solution for reducing, volume, and reusing waste.

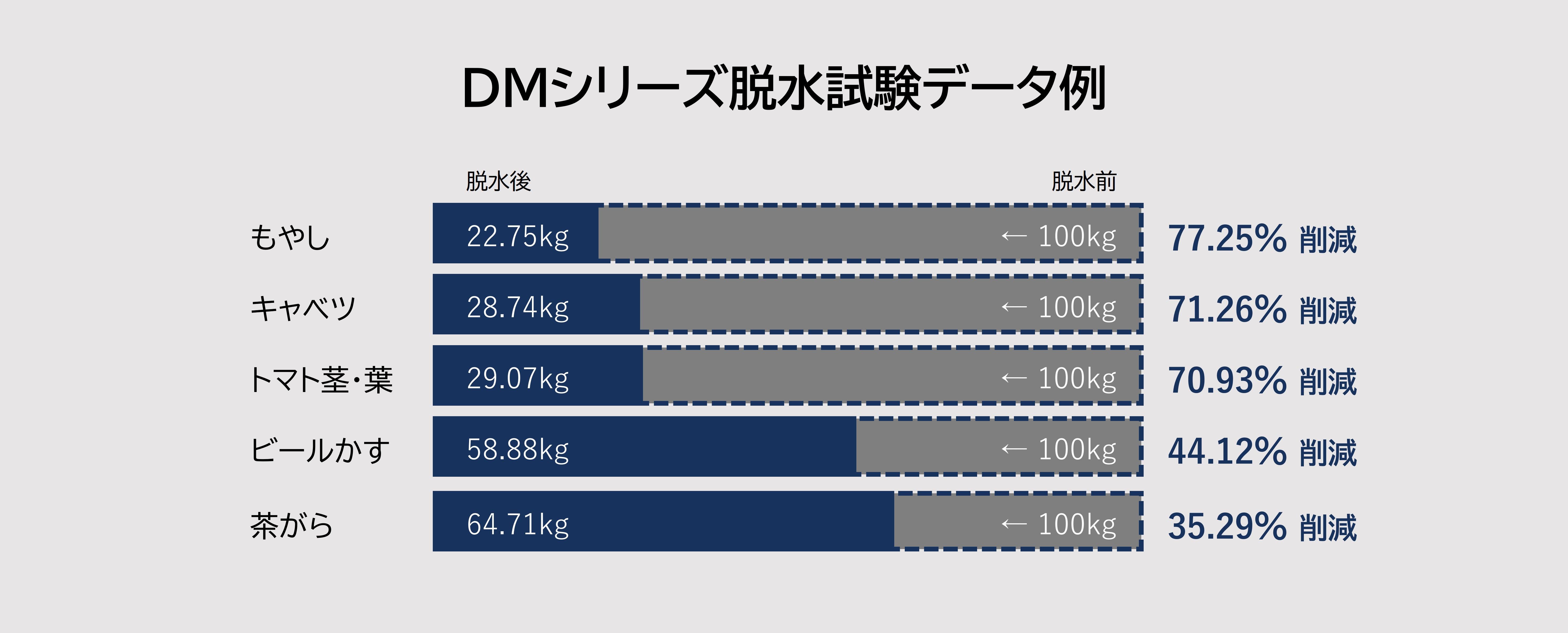

It can squeeze food waste such as bean sprouts, cabbage, various vegetables, fruits, and used tea leaves with overwhelming dehydration efficiency, making it possible to significantly reduce weight. For bean sprouts with a high moisture content, we achieved a weight reduction of over 70% compared to before dehydration.

By dehydrating food waste with the DMseries and significantly reducing its weight and volume, it is possible to reduce waste processing costs and CO2 emissions generated during incineration.

In addition, food waste has traditionally been processed at a high cost, but by dehydrating it and reducing its water content, it becomes easier to process it for reuse. It can be recycled as feed.

Efforts toward sustainability and reducing environmental impact lead to improved corporate brand and social credibility.

Dehydration results

Organic matter | Bean sprouts, cabbage, lettuce, Chinese cabbage, carrots, radish, burdock, onions, bean sprouts, tomatoes, young barley leaves, various used tea leaves, olives, tangerines, pineapples, apples, coconuts, pulp, etc.

Inorganic materials|waste plastic, paint scum, non-woven fabric, etc.

Effects of introducing a screw press dehydrator

Effect 1|Cost reduction

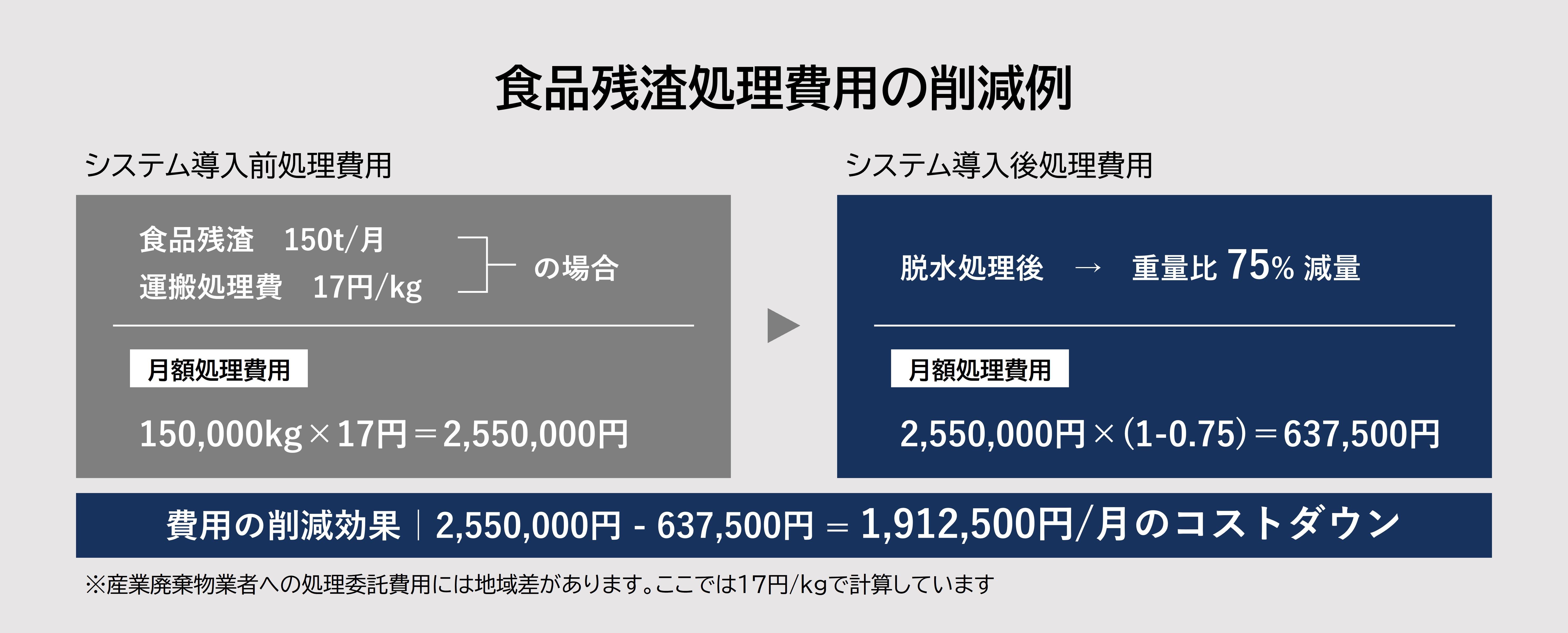

With its overwhelming dehydration efficiency, it reduces the amount of food residue and other waste, contributing to a significant reduction in industrial waste disposal costs. It also makes it possible to reduce labor costs by saving labor in the industrial waste treatment process.

Effect 2|Recycling

By turning squeezed waste into feed and recycling filtrate, we can create an eco-cycle that leads to zero emissions.

Effect 3|Reduce CO2

By reducing the amount of waste, the amount of incineration by industrial waste companies is reduced. It can significantly reduce the enormous amount of CO2 emitted through incineration and contribute to the realization of a low-carbon society.

Effect 4|Contribute to CSR

We contribute to the CSR activities and status improvement of companies, such as achieving zero emissions in the food society and realizing production systems that can be completed at our own factories.

Effect 5 | Improved work environment

With equipment that does not generate vibrations, noise, or scattering of processed materials, we have created a clean and stress-free working environment that is free from odors and dirt. It also contributes to improving the corporate image.

Features of the screw press dehydrator “DMseries”

Food waste fed into the DMseries is filtered and dehydrated using a wedge wire screen, and separated into filtrate and squeezed waste. The dehydrated pomace is discharged from the tip of the dehydrator into a container, and the filtrate is discharged into a septic tank.

Feature 1 | Simple design for easy cleaning and maintenance

The structure is simple, the water removal rate is good, and it is hard to get clogged, so it takes a short time to clean after work. There are few consumable parts and maintenance is easy. Realizes easy maintenance.

◆ Wedge wire screen with wide discharge opening

The screen uses 0.3-1.0mm wedge wire. The mesh structure has a higher discharge aperture ratio than punched metal screens and exhibits high separation performance.

◆Tapered screw that increases compression ratio

The screw shaft has a tapered design. The shape narrows toward the discharge port, which reproduces an extremely high compression rate and enables an improvement in the weight loss rate.

Feature 2|Easy operation for anyone

The operator simply adjusts the rotation speed and pressure. The simple operation system allows anyone to easily perform high-efficiency dehydration.

Feature 3 | Realization of labor saving and continuous autonomous driving

A method that allows continuous operation simply by continuously adding objects. High productivity can be achieved with minimal personnel.

Example of dehydration test data / Example of reducing food residue processing costs

These features provide overwhelming dehydration efficiency with high separation performance and volume reduction rate. This greatly contributes to reducing waste volume and processing costs. Among waste materials, we specialize in processing cut vegetables and cut fruits, which have extremely high moisture content.

Introduction example

It is often installed in food factories, juice extraction factories, etc. that handle vegetables and fruits with high moisture content. It is also used as an extractor for fruit juice extraction lines.

Inquiry

The DMseries screw press dehydrator has a lineup of seven types: DM10 (processing capacity 40-60kg) to DM60 (processing capacity 3000-5000kg). It can be used in accordance with the needs of customers such as food factories, juice extraction factories, and sake breweries.

For inquiries about reducing waste treatment costs or for details on product lineup and specifications, please contact us using the form below.