Do you have any problems?

- Want to reduce food waste disposal costs

- I am worried about the bad smell of garbage until it is collected

- I'm in trouble because I don't have a space to put a large amount of raw garbage.

- I want to work on reducing food waste in the employee cafeteria through environmental activities

What is E-Cube

Garbage processors can be broadly classified into three types, depending on the processing method: incineration type, drying type, and microbial decomposition type.

E-cube is a 100% volume reduction, completely self-contained garbage processor that converts kitchen garbage and pre-cooking residue (*1) into water using the power of microorganisms.

Microorganisms decompose garbage as it is ground, and the remaining water after treatment is finished can be discharged into a septic tank or sewage.

Various sizes are available according to the amount of garbage discharged, from a minimum of 10 kg to a maximum of 750 kg.

*1: Garbage, leftovers before cooking | food that can be chewed and digested by humans, leftover food, cut off vegetables, leftovers from cutting fish, etc.

Three features of E-Cube

E-cube can be used by anyone without draining water or taking out residuals before putting it in. Since garbage is turned into water after treatment, there is no need to dispose of leftovers, making running costs low.

In addition, food waste can be put in at any time, so it eliminates the odor and space problems when storing food waste.

Object to be processed

〇 Items that can be processed

Chewable items, grains, livestock products, edible parts of seafood, vegetables, fruits, processed foods, etc.

△ Poor handling

Do not use strong fibrous materials such as corn husks.

If the ratio of rice (leftover food) exceeds 70%, the processing capacity drops *Replenishment of Bio Chaff D (for large amounts of leftover food)

× Items that cannot be processed

Metals, thick bones of tuna, pigs, cows, etc., shellfish, corn cobs, fibrous skins of corn, bamboo shoots, bananas, etc., oils and fats, large amounts of onion skins, seeds (pickled plum seeds, etc.), etc. * A small amount (up to 2%) is acceptable

maintenance

|

frequency |

content |

|

every day |

Check the control panel lamp |

|

If you find a foreign object, take it out |

|

|

every week |

Check the amount in the tank |

|

Rinse away food waste adhering to the side wall inside the tank |

|

|

monthly |

Wipe the level sensor dry |

|

Drain cleaning |

|

|

once every 3 months |

Replenish the biochaff (fungus bed) (*2) |

|

once every six months |

Lubricate the stirrer shaft bearings, gears, and chains. |

*2: The replenishment amount varies depending on the model.

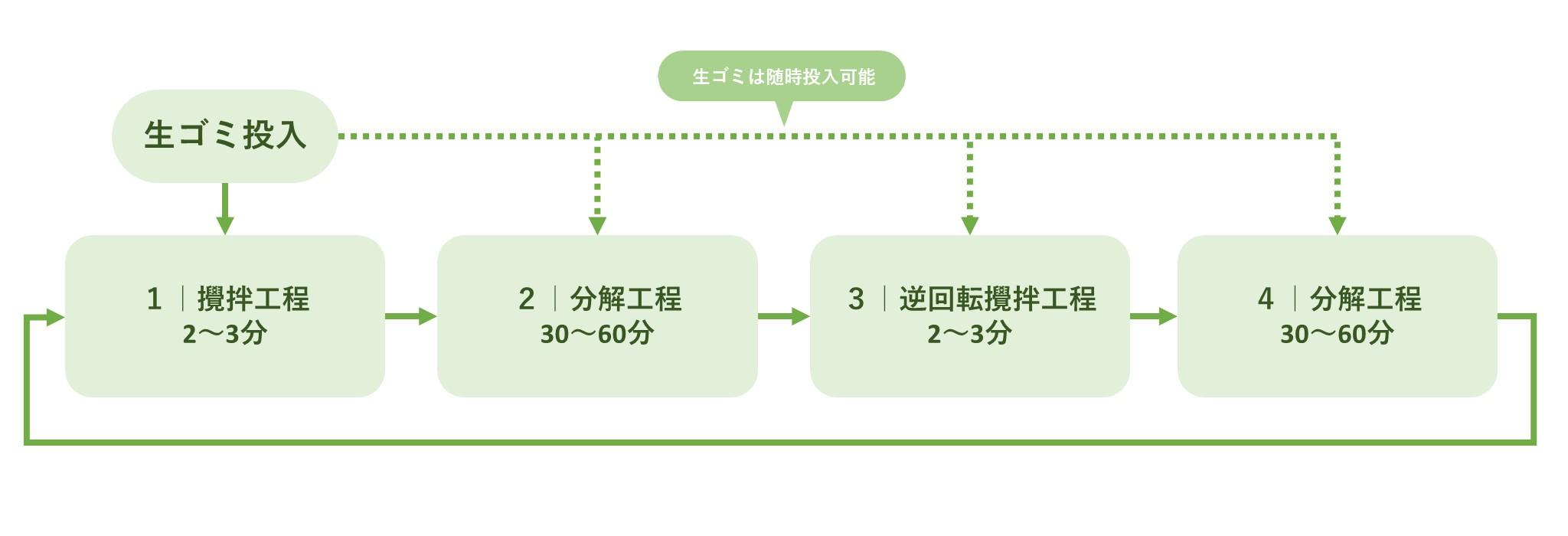

Processing process of E-cube

function

| input port | Even during stirring, it stops at the same time as the lid is opened. (Safety device) |

| warming heater | The inside of the tank is heated and controlled at the optimal temperature for fermentation decomposition (around 35°C, the same as human body temperature). |

| stirring | The fungus bed, garbage, enzymes, etc. are evenly mixed to promote efficient fermentation and decomposition. (intermittent stirring function) |

| water supply | Automatic intermittent water supply for promotion of fermentation decomposition, temperature control in the tank, and deodorizing effect. |

| drainage | Drains water after decomposition. Wastewater is treated as miscellaneous wastewater (sewage). |

| Bio chaff (fungus bed) | A biochaff is composed of Azeron spp. using rice husks as a matrix. 30% of the initial amount is replenished annually during rated operation. |

Case study

It has been installed in various facilities such as stations, hotels, shopping malls, employee cafeterias, lunch centers, factories, hospitals, and nursery schools.

Inquiry

E-cube has a lineup of 13 types with a processing capacity of 10 to 750 kg. We offer a variety of sizes to suit your emissions requirements.

From small-scale facilities such as nursery schools and restaurants to large-scale facilities such as hotels, hospitals, and food service centers, we can accommodate your needs. For more information on the lineup and specifications, please contact us using the form below.