Inductors and capacitors must be selected according to the application. We will explain the points that need to be considered for selection.

The content of this time is Part 1 “Selection of Power Inductor”.

If you want to see other articles, there is a summary page, so please take a look there.

Power inductor selection flow

There are several points that must be considered when selecting power inductors for use in power circuits. This time, I will explain three points to note.

I think there are many cases like this as a general design flow.

・Selection of power supply IC

・Determination of switching frequency

・Determination of inductance

・Parts selection based on inductance and rated current

This time, let's consider the specifications of input VIN = 12V, output VOUT = 3.3V, and load current IOUT = 4A.

As related articles, please refer to "Design Method of Switching Regulator" and "Constant Calculation and Precautions for Step-Down DC/DC Converter".

Select LT8640 as the power supply IC and 1MHz as the switching frequency.

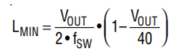

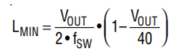

The inductance is Lmin = 1.51μH from the following formula described in the datasheet.

Precautions when selecting components 1: Inductance change

Once the necessary inductance has been determined, it becomes possible to select components. However, if the inductance is increased, the shape will become larger, so select the necessary and sufficient inductance value.

In general, E12 series constants are often lined up, so we will select 2.2μH this time.

For the E series, please refer to the related article "Bits of Knowledge: Values of Resistors and Capacitors".

There are two points to check for inductors.

・Inductance tolerance

・DC superimposition characteristics

Consider tolerance first. Most power inductors have a tolerance of 20-30%. In the case of 2.2μH±20%, the lower limit is 1.76μH, which satisfies the minimum value required by the power supply IC.

If 1.8 µH is selected, it will not meet the requirements if it is close to the lower tolerance limit.

Next, let us consider DC superimposition characteristics. The core material used is important for this property.

Here, we will compare the ferrite type and the metal type, which are widely distributed.

Figure 1 shows the characteristics of two Wurth Electronics inductors that have the same inductance and similar rated currents.

Figure 1: Comparison of DC superimposition characteristics

744777002 uses a ferritic core material. The characteristic is that the inductance continues for a period of little change, and when it starts to decrease, it drops sharply.

When selecting a ferrite type, select the one whose usage area is the period with little inductance change.

74438366022 uses a metal core material. It can be seen that the inductance decreases gradually as the current increases.

It can be seen that the metal system has the property of being difficult to magnetically saturate.

This change in inductance is caused by a change in the magnetic permeability μ of the core material. Increasing the current further reduces the inductance and causes magnetic saturation.

Inductance change also changes with operating temperature. Figure 2 shows the inductance change at 100°C for the two types of inductors mentioned above.

Figure 2: Comparison of DC superimposition characteristics (100°C)

From Fig. 2, it can be seen that the metal system does not show much temperature change, but the ferrite system has a smaller point at which the inductance starts to decrease.

Temperature characteristics must also be considered for applications used in high temperature environments.

Precautions when selecting parts 2: Consideration of overcurrent

Selection of the power inductor is a point that should be considered even in the event of an abnormality such as a short circuit. Most power supply ICs have an overcurrent protection function.

However, when the inductor becomes magnetically saturated, a steep current change occurs as shown in Figure 3.

Figure 3: Behavior during magnetic saturation

From Analog Dialogue, Analog Devices

Except for special power supply ICs, it may not be possible to respond to sudden current changes, and expected operation may not be obtained.

The LT8640 has overcurrent protection values specified in Figure 4, so select an inductor that does not saturate even when 12.5A flows.

Figure 4: LT8640 overcurrent holding value

From Analog Devices, LT8640 datasheet

The 744777002 investigated this time is not suitable for use with this specification because the inductance drops to about -90% at 12.5A.

The 74438366022 only drops about -20% at 12.5A, so it can be considered usable.

Precautions when selecting parts 3: Temperature rise

Power inductors must be used within the operating temperature range of ambient temperature + self-rise.

電源回路に使用するパワーインダクターの自己上昇についてはDC損失とAC損失を考慮する必要があります。

DC loss can be calculated by the current rating of the inductor and the current used.

As a related article, please refer to "Basics of LC - Part 3 Characteristics of Inductors".

However, it is difficult to calculate AC loss because it requires information such as core material characteristics and winding information that is not disclosed, so we use simulation tools.

Figure 5 shows the AC loss simulation results for 74438366022 in this specification using Wurth Electronics "REDEXPERT".

Figure 5: AC loss simulation

“REDEXPERT” will give you the specs and the part number and it will give you the DC and AC loss values and the resulting self-rise.

It can be confirmed that the current specification is a self-rise of about 20°C.

Information on simulation tools

Inquiry / Quotation

If you have any questions or requests for quotations regarding this product, please contact us using the form below.

Click here to buy now

Wurth Electronics Manufacturer Information Top

If you would like to return to the Wurth Electronics manufacturer information top page, please click below.