Small savings make a big difference for data centers

The size of the data center is really, really big. Do an image search for "data center" and you'll find large, featureless buildings and multiple aerial images. They are often newly built on similarly vast and featureless plains. What this shows is that while new buildings are already sprawling, data center owners want to leave plenty of room for future expansion.

Amazon, Apple, Facebook, Google, and many lesser-known organizations operate such vast data centers at multiple sites around the world. For commercial reasons, we never say exactly how many servers we have, but it's common to think there are millions of servers in a data center.

This is where the engineering challenge arises. You have to pay for the energy that goes into these data centers. When you're running millions of servers, the energy savings per machine when considered holistically can be very significant.

One of the key areas is the power supply for each server. This can have a significant impact on overall energy usage. Among them are some basic problems that are relatively easy to deal with. For example, using a higher input voltage on the power supply will result in lower I2R heating losses than using a lower input voltage. It also helps to avoid over-specifying the power supply. It doesn't make sense to have a 500W supply to supply 300W. And then there's the basic conversion efficiency of the power supply itself. It is estimated that many server power supplies operate at 65% to 80% efficiency. So, in the worst case, a third of the energy you're paying for could be wasted in your data center instead of being used for its intended purpose.

More complex power supply designs can push this efficiency up to 90% or more. However, many designers still do not understand the simpler way to increase efficiency: how to use more efficient semiconductor devices.

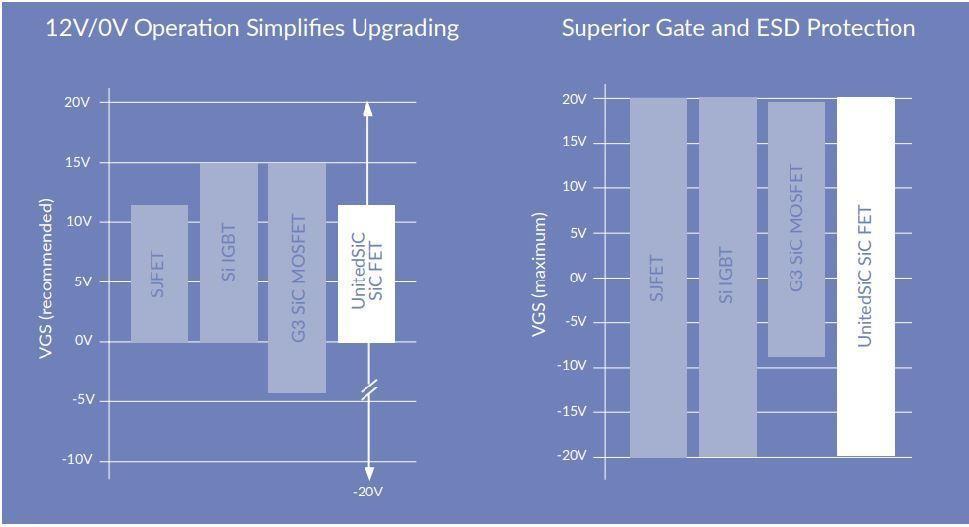

For example, Qorvo packages a normally-on silicon carbide (SiC) JFET with a Si MOSFET in a cascode architecture to produce a normally-off SiCFET device. It can be driven in the same way as Si IGBTs, Si FETs, SiC MOSFETs and Si superjunction devices, but has very low gate charge and excellent reverse recovery characteristics, which can be exploited for high efficiency You can build a switching power supply.

Components such as Qorvo's SiC FETs have several other advantages. The first is very low RDS(on), which reduces internal losses. This directly relates to increased efficiency. Second, it is available in a surface-mount DFN8x8 package, already used in space-constrained applications such as telecommunications equipment. By simply changing existing devices to these SiCFETs, designers can develop higher density power supplies within the existing thermal budget of a case or rack.

As mentioned at the beginning of this article, data centers are likely to get even bigger in the future. Reducing the energy consumed by servers not only saves on cooling costs, but also provides an opportunity to protect or improve system reliability. Optimization involves making a series of highly complex tradeoffs between capital and operating costs, energy efficiency and compute density, reliability, and more. The advantage of replacing SiC semiconductors for server power supplies is that it is an easy and cost-effective move, offering many small savings that make a big and worthwhile difference.

Inquiry

If you have any questions regarding this article, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.