In recent years, various in-vehicle applications have been implemented in automobiles, and many problems have arisen in power supply circuits. Engineers are required to solve various design issues in a short development period, such as "I want to reduce noise," "I want to reduce circuit area," "I want to reduce power consumption," and "I need a device that complies with the ASIL standard." increase.

For those who have these issues, we recommend the power supply ICs of the former Maxim Integrated, which was integrated with Analog Devices. Here, we will introduce typical issues in power supply circuits for automotive applications, the features of Analog Devices (formerly Maxim) automotive power supply ICs, and recommended power supply ICs.

Issues in power supply design for automotive applications (1) Noise countermeasures

Technologies such as electrification, autonomous driving, and ADAS (advanced driver assistance systems) are rapidly spreading, and in-vehicle applications, from instruments to cruise control, continue to grow. High levels of functional safety and reliability are required for automotive applications because they are directly related to human life.

Under these circumstances, noise countermeasures have become a major issue in power supply design. Automotive applications require very strict standards such as CISPR25 to avoid malfunctions due to noise. Therefore, we often hear from engineers that they are looking for low-noise devices. Analog Devices (formerly Maxim) power supply ICs combine several techniques to reduce EMI noise.

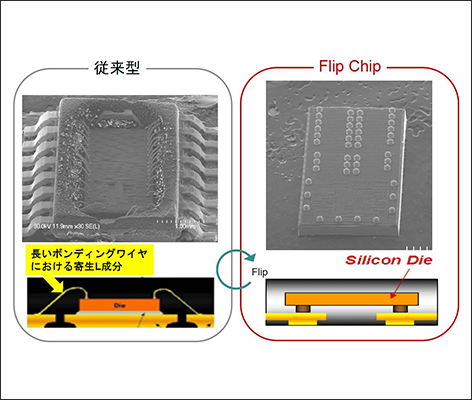

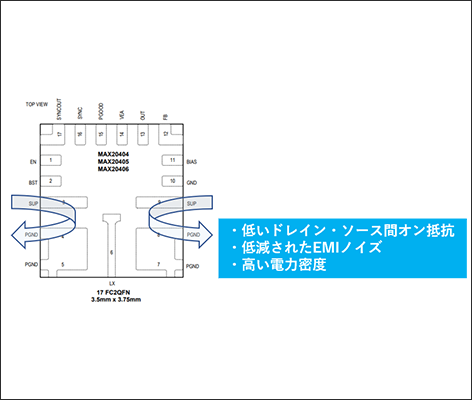

The internal wiring uses a flip-chip structure instead of the conventional bonding wire connection. Noise can be reduced even at high switching frequencies because wires with large noise effects are no longer needed. Inside the package, the input (SUP) and ground (PGND) have a symmetrical structure, which is effective in suppressing EMI noise.

It also uses spread spectrum technology to reduce EMI. It has a short minimum on-time and allows operation at a switching frequency of 2MHz. Adopting a power supply IC from Analog Devices (formerly Maxim) enables an effective approach to noise issues.

Challenges of Power Supply Design in Automotive Applications (2) Miniaturization

Another major challenge is miniaturization of the power supply circuit. As applications have become smaller in recent years, the mounting space for power supply circuits has become extremely small. A power supply circuit consists of multiple parts such as a power supply IC, inductor, resistor, and capacitor. Therefore, when working on miniaturization, it is important to comprehensively consider the circuit area, number of parts, power density, heat generation, cost, etc., including peripheral parts.

Analog Devices (formerly Maxim) power IC solutions have approximately a 60 % footprint reduction compared to typical power ICs. One of the technologies that contributed to its realization is the improvement of power density through the adoption of a 90 nm process die size. The flip-chip structure also contributes to the miniaturization of the package.

In addition, Analog Devices (formerly Maxim) power supply ICs feature excellent responsiveness and low on-resistance of the built-in FETs. Therefore, it is possible to reduce peripheral components such as output capacitors and temperature countermeasure devices. Fixed output and fixed frequency options are also available to reduce external components.

Power supply ICs from Analog Devices (formerly Maxim) enable significant miniaturization of the entire power supply circuit.

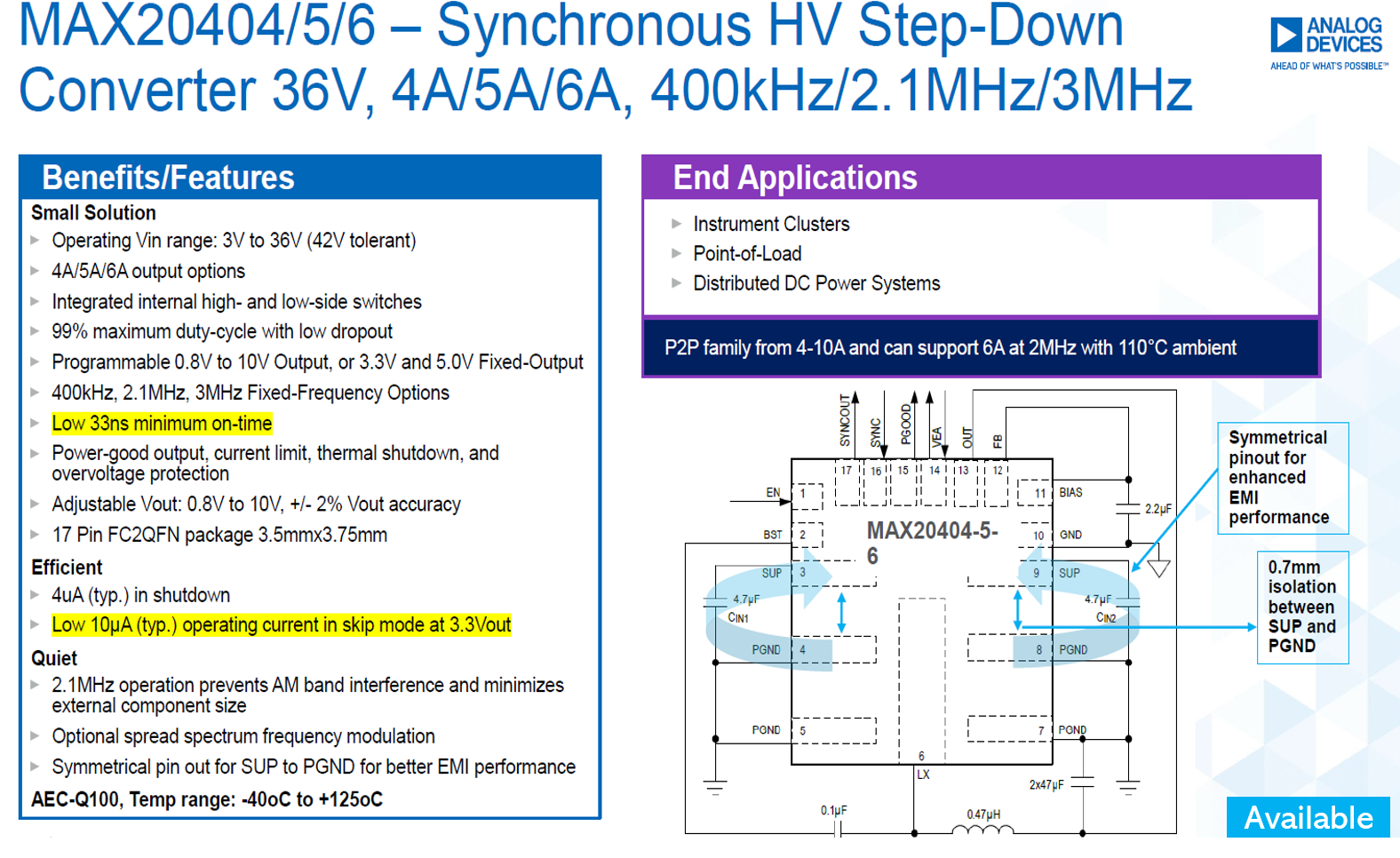

Maxim power supply ICs that solve design challenges (1) Highly scalable P90 series "MAX20404/5/6" and "MAX20408/10"

Now, we will specifically introduce the power supply IC solutions from Analog Devices (formerly Maxim) that are recommended for power supply circuit design in automotive applications. All of them have functions that contribute to solving the main issues of "low noise" and "miniaturization."

90 nm process devices such as the "P90" series "MAX20404/5/6" and "MAX20408/10" are attractive for their high scalability. With the same footprint, we offer a rich lineup that supports 4, 5, 6, 8, and 10A. It is widely used in automotive primary power supplies (12V system).

In recent years, design schedules have become very tight due to the need to get products to market quickly. By adopting the highly scalable P90 series, it is possible to deploy power supply circuits with a common footprint for multiple applications. Design assets can be reused, shortening the development period, reducing costs, and improving design flexibility.

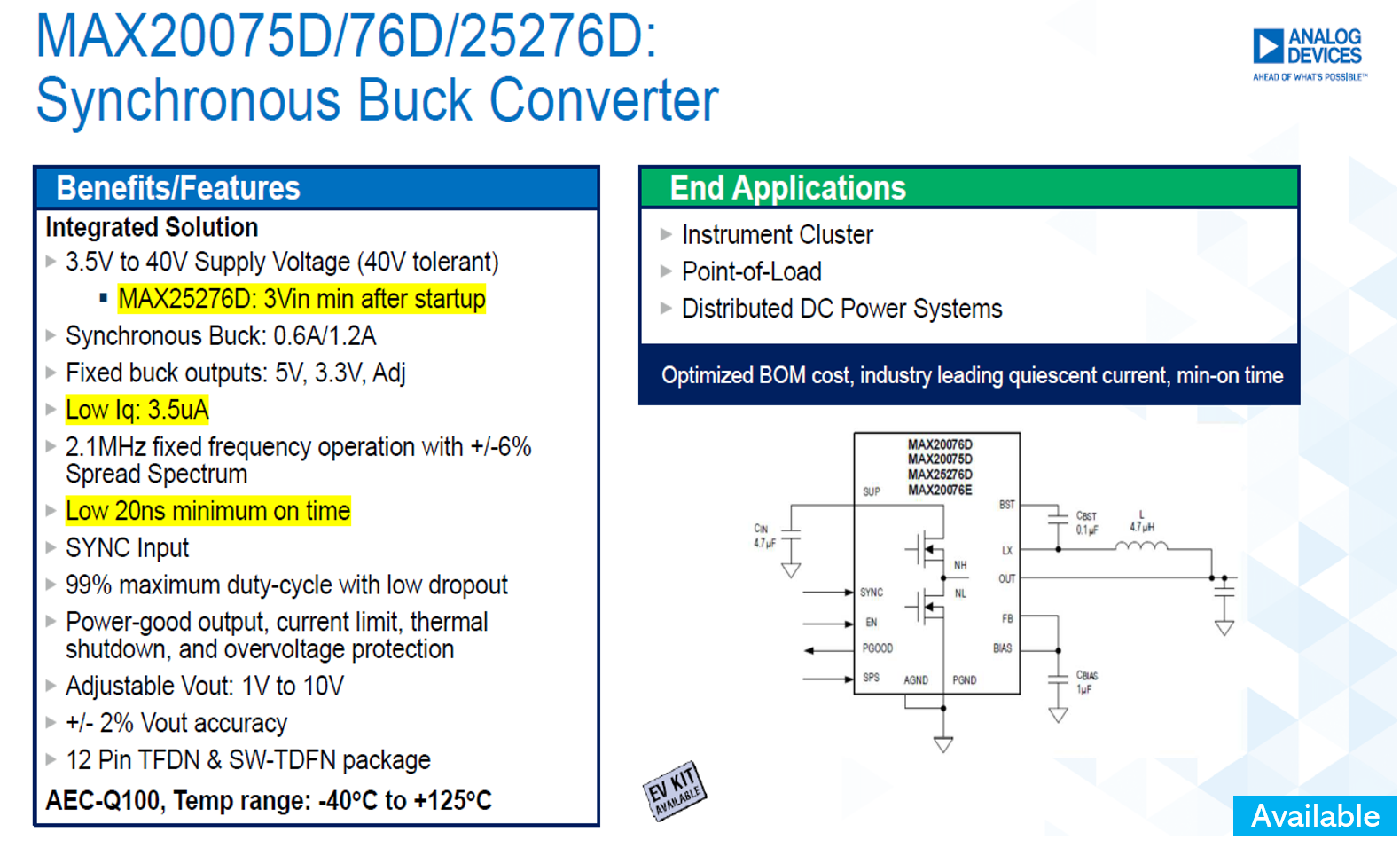

Maxim power supply ICs that solve design challenges (2) Achieve ultra-low Iq of 3.5μA "MAX25231/232/223" "MAX20075D/6D/7/9"

"MAX25231/232/223" and "MAX20075D/6D/7/9" released as "Ultra-Low Iq Family" can greatly contribute to the reduction of power consumption. In recent years, it has been widely adopted for automotive applications that require low power consumption.

In automotive applications, various control boards are installed inside, so there are many cases where power consumption limits occur for each function, which poses a design challenge for OEM products. Therefore, the quiescent current (Iq) value is one of the important items.

Devices in the 'Ultra-Low Iq Family', including the MAX20075, offer very low Iq values of 3.5 μA. This power supply IC is recommended for those who are concerned about power consumption restrictions in OEM products.

Maxim Power Supply IC Solves Design Challenges(3) Compatible with ASIL Standards "MAX20411" and "MAX20011"

Automobile safety standard ASIL-D corresponds to MAX20411, MAX20011 is.

Not previously offered by Analog Devices ASIL Compatible power supply I C joined the lineup with the integration of Maxim. In-vehicle infotainment system, cluster system, ADAS ECU, inverters, camera modules, etc.

old Maxim of ASIL Power supply line-up I C In addition to the general protection functions installed in , various monitoring functions and functions required for self-diagnosis are implemented. ASIL A power supply that meets strict safety requirements I C is.

In this article, we will introduce the best solutions for problem solving for those who design power supply circuits for in-vehicle applications. ADI (Maxim) power supply I C introduced. Evaluation boards for each of the devices introduced are available. Please do not hesitate to contact us.

Application example

・ ADAS (Advanced Driver Assistance System)

·Electric car

・In-vehicle camera module

Click here to purchase products

Click here for manufacturer site/other related links

- <Technical Article> Smaller ECUs for ADAS: Lumping Power Around the Signal Chain

- <Technical Article> Balancing Power Requirements for ADAS Applications

- What is a secondary power supply that solves the size and noise design issues associated with the increase in power of automotive ECUs?

- Clears CISPR25 Class5 requirements! Switching regulator that facilitates noise design for automotive ECUs

- Ideal Diode Solution to Enhance Automotive ECU Safety and Solve Heat and Space Issues

Inquiry

If you have any questions regarding this article, please contact us below.

Analog Devices Manufacturer Information Top

If you want to return to Analog Devices Manufacturer Information Top, please click the button below.