product

- Transportation/storage status monitoring and tracking service - Macnica Tracks® -

- Transportation/storage status monitoring and tracking terminal - Qualcomm® QTS110 -

- Location monitoring and tracking device - Qualcomm® QTS112 -

- [FAQ] Transportation/storage condition monitoring and tracking service - Macnica Tracks® -

- List of documents

How to use technology to solve the logistics "waiting for goods" problem

Introduction

The "loading waiting problem," a serious issue in the logistics industry, is causing drivers to spend long hours tied up, lowering efficiency throughout the industry and exacerbating labor shortages. 2024 With the new law coming into force in 2019, there is an urgent need to resolve this issue. Towards resolving the "waiting for shipment problem"How to use technology We will introduce you to the following.

“Explains how "reducing waiting time for shipments" is possible by utilizing IT equipment that is quick to implement, easy to use, and cost-effective. I will.

Reducing "waiting time" in logistics is the key to solving the 2024 problem

Current status and issues of logistics

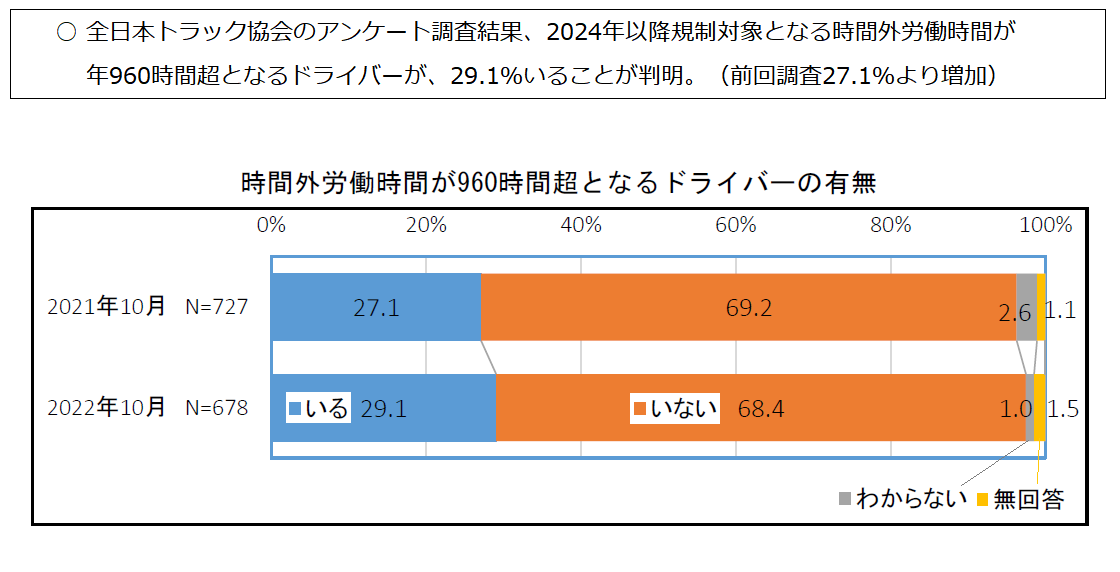

Japan's logistics industry is currently facing serious challenges of labor shortages and long working hours. There is a noticeable shortage of drivers, especially in urban areas, which is resulting in an increasing number of delayed deliveries and overcrowded delivery schedules. This situation is resulting in further extensions of working hours, and the working environment for drivers continues to deteriorate significantly. As a result, employees are overburdened, which is having a negative impact on the securing and retention of new talent. In the midst of this, a cap of 960 hours per year (excluding holiday work) will be imposed on overtime work for driver work from April 2024, which will have a major impact on logistics. (See the figure below)

Challenges facing the logistics industry and countermeasures (2022/12/13)

The key to solving these problems is efficiency and leveraging technology.

By visualizing and analyzing data on transportation status, it is expected that transportation efficiency will improve, waiting time will be reduced, and productivity will be improved. In addition, by visualizing the entire logistics process and promoting standardization and automation, it will be possible to eliminate waste and proceed with work more efficiently. Through such efforts, it is becoming essential to address the challenges facing the entire logistics industry and aim for sustainable growth.

"Utilizing technology:By utilizing the transportation/storage status monitoring and tracking service "Macnica Tracks™"..."

The two-hour rule in logistics*: Shippers and transport companies need to cooperate and take thorough measures

* "Guidelines for shippers and logistics companies' efforts to streamline logistics and improve productivity"

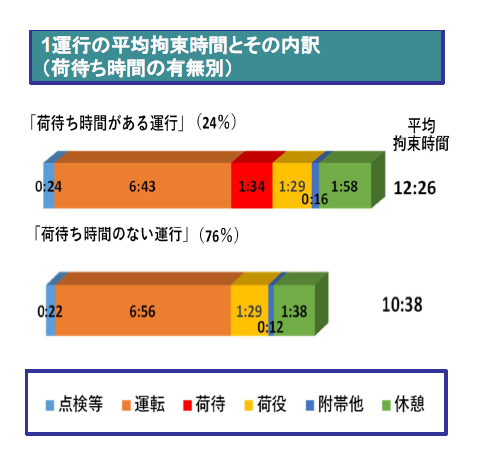

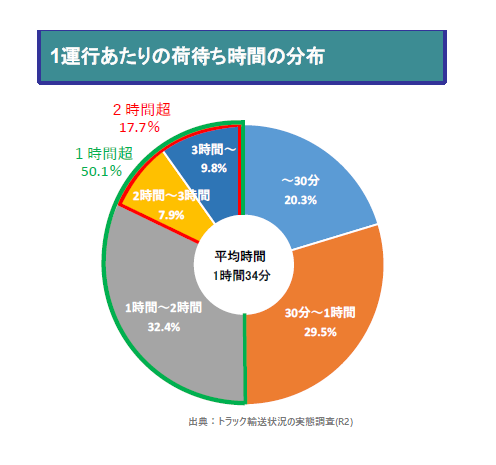

As those of you in the logistics industry will be aware, there is a "two-hour rule" in place that aims to complete vehicle loading and waiting within two hours.

The purpose of this rule is to prevent a decline in transportation efficiency due to long waiting times and loading and unloading, while at the same time improving the working environment for truck drivers. The background to this is the harsh reality of the logistics industry due to a shortage of drivers and low wages, and this rule is positioned as an important measure to improve the working environment. Specifically, if a waiting time of more than two hours occurs, it will affect the driver's entire work schedule. For example, it may be necessary to adjust the start time of work, or the next delivery schedule may be delayed.

This could lead to a significant decline in logistics efficiency, increased transportation costs, and further deterioration of working conditions. In addition, relevant laws and guidelines also state policies for reducing waiting times and proper management, and compliance with these is required across the industry.

By observing this two-hour rule, it is expected that the working environment for drivers will improve, the efficiency of the logistics system will increase, and the productivity of the logistics industry as a whole will increase, which will ultimately lead to the securing of drivers and the realization of a sustainable working environment. It is said that it is important for shippers and transport companies to cooperate and make efforts to strictly enforce this rule.

Main causes of waiting time

So what is the main cause of waiting times? The main causes are "schedule inconsistencies and inefficient management in the logistics process."

This occurs when insufficient information sharing between transport companies and logistics centers leads to discrepancies in the timing of cargo handover and loading/unloading.

For example, if the estimated arrival time is not clearly shared between the warehouse and the driver, the warehouse will be underprepared and the driver will have to wait outside the facility for several hours. In addition, there may be a shortage of loading and unloading space, and waiting times tend to increase even more during peak times when shipments and deliveries are concentrated. If such problems occur frequently, it will lead to a deterioration of the working environment of truck drivers and a decrease in the productivity of the entire logistics industry. Considering the causes, it is possible to reduce waiting times by "smooth information sharing". To do this, we can see a way to solve many issues by introducing new technology and appropriate management systems and establishing a system for sharing schedules and the status of logistics centers in real time.

Why is it necessary to record cargo waiting time?

The obligation to record waiting times plays an important role in efficient logistics management and legal compliance. The time spent waiting for loading and unloading is one of the factors that greatly affects the overall efficiency of many logistics sites. Properly recording this time makes it possible to identify waste and problems and build a data base for operational improvements.

Accurately recording this time increases transparency between shippers and carriers. For example, by using the recorded information to identify specific locations or shippers where shipments are likely to be delayed and taking measures to improve the situation, the efficiency of the entire operation can be improved. Furthermore, by using the data to set standard times, it becomes possible to formulate appropriate estimates and transportation schedules, allowing the entire logistics process to proceed smoothly.

By understanding and accurately recording waiting times, we can improve work efficiency.

In this way, recording waiting times is not just an operational hassle, but an essential process for efficient operation and improved competitiveness in the entire logistics industry. It also improves the working environment, making it easier for drivers to work, and helps to address labor shortages. Accurately understanding waiting times and using them to make improvements is the key to solving the challenges facing the logistics industry, and is an essential initiative for building a sustainable supply chain.

Using technology to reduce waiting and loading times

The key to taking rational measures is to "use technology"

I have mentioned the problem of waiting for shipments in logistics, but the key to a rational solution is to utilize technology.

Let's build a sustainable logistics network by visualizing transportation status and introducing a reservation reception system to improve loading efficiency. For example, one solution is to adopt a system that uses artificial intelligence (AI) to predict demand, develop optimal delivery routes, and reduce waiting time. This will enable shippers and the transportation industry to share data and strengthen cooperation. In order to maintain stable logistics after 2024, cooperation and continuous improvement across the industry is essential. In addition to improving the working environment of truck drivers, shippers are also required to fulfill their corporate social responsibility and work together to build a logistics system with a long-term vision. Through this process, let's realize the future of logistics where efficiency and compliance are compatible.

By using the transportation/storage status monitoring and tracking service "Macnica Tracks™"...

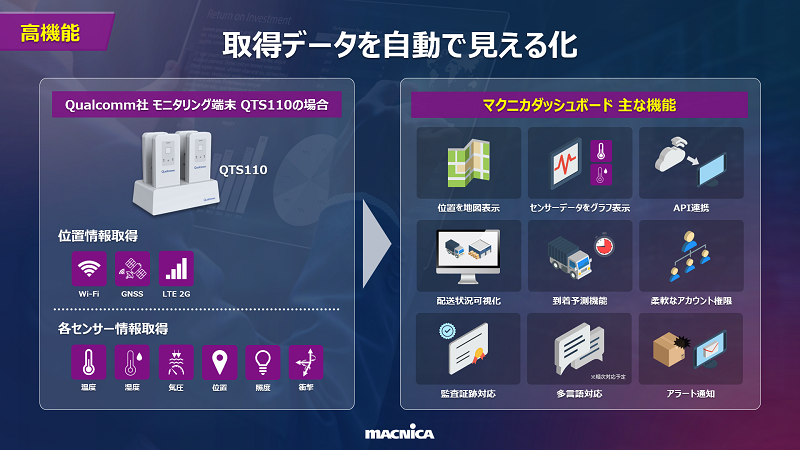

In Macnica, the IoT Macnica cloud service that visualizes and easily manages location information and sensor information (position, temperature and humidity, impact, drop, opening) acquired by monitoring terminals" Macnica Tracks™”We provide:

Macnica Tracks™ can be used to reduce waiting times in the logistics industry. This technology is designed to: It has the function of enhancing schedule management and information sharing in real time.

Providing a mechanism to facilitate efficient collaboration between truck drivers, warehouse workers, and shippers I will. This system significantly reduces waste throughout the transportation process and enables high productivity.

Figure 1. An example of Macnica Tracks™ functionality

Visualization of delivery status

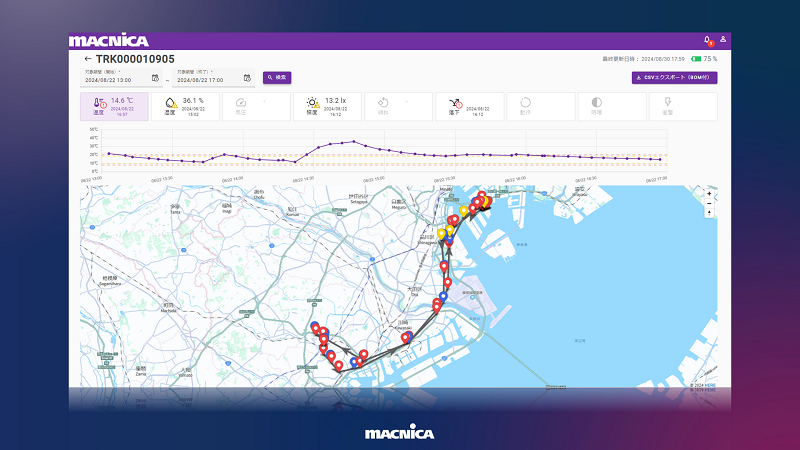

By installing Macnica Tracks™, you can visualize the delivery status of each delivery job (delivery started, delayed, arriving at intermediate destination, arriving at destination, etc.) in a list on the screen.

By more accurately understanding the timing of incoming and outgoing shipments and adjusting on-site work schedules, this will result in a significant reduction in waiting times.

Push notifications via email

By utilizing the geofence function (a function that uses location information measured by the device to detect entry and exit from a pre-set area), delivery status can be notified in real time by email, so that arrival schedules can be detected in advance and warehouse workers can prepare for unloading before the cargo arrives. (Example of setting: Notifying delivery status at the stop before the destination)

Understanding the factors behind destination dwell time (distinguishing between waiting for cargo and loading/unloading time)

Furthermore, we have heard that "although we are already using real-time positioning with GPS etc., we cannot distinguish the waiting time after arriving at the destination and the actual time required for loading and unloading!" However, by utilizing the opening detection function using the illuminance sensor of Macnica Tracks™, it is possible to automatically detect the opening of a container, grasp the breakdown of the time the container is staying at the destination, and perform highly accurate analysis.

Reducing the burden on drivers and office workers

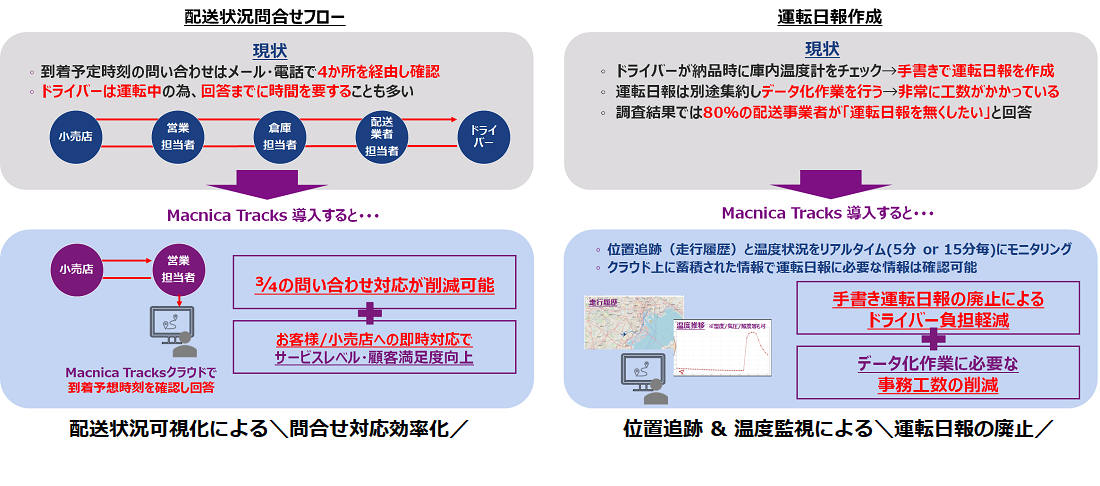

Macnica Tracks™ can also be used to streamline and reduce administrative tasks such as checking delivery status and daily driving reports. Specifically, confirmation tasks that previously required phone calls between supply chains can now be visualized and shared in real time as data, eliminating the need for inquiries. Furthermore, drivers no longer need to write notes by hand, reducing administrative man-hours. (See Figure 2) This also contributes to ensuring efficient delivery routes and preventing sudden delays, improving the performance of the overall supply chain.

Figure 2. Example of the benefits of using Macnica Tracks™

Macnica Tracks™ is attracting attention as an effective solution not only for improving efficiency at logistics sites, but also for minimizing logistics costs. This has the potential to be an effective solution to the labor shortage and 2024 problem facing the logistics industry. The reduction in incidental work due to the aforementioned time saving also contributes greatly to improving the working environment for drivers and workers. By adopting such cutting-edge technology, it can be one of the means to pave the way for providing better services to society as a whole while increasing competitiveness.

There are an increasing number of cases where people are considering replacing their GPS trackers with "Macnica Tracks™".

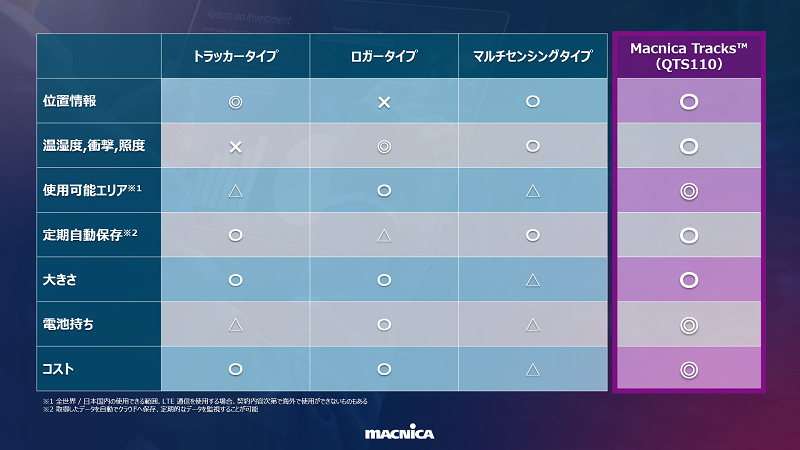

When it comes to incorporating the latest technology, there are many types of monitoring devices, such as trackers, loggers, and multi-sensing devices. Although they are good at obtaining location information, there are many complaints that they cannot obtain temperature or impact data, and although they can obtain a wide variety of data, they are expensive. Macnica Tracks™ is.

Macnica Tracks™ Compared to various monitoring terminals, it has many advantages (see Figure 3), and can also be introduced at low cost, so there are an increasing number of customers who are considering replacing it or who want to conduct demonstration experiments first. By using it in conjunction with a digital tachograph already installed for labor management, etc., it is possible to perform GDP-compliant status management more easily and inexpensively than by changing the model of the digital tachograph, which is also appreciated. From both shippers and transport companies We appreciate your interest.

"First, let's take a look at the actual dashboard screen."

"I want to know more about the product"

"I would like to know how it can be used if it is introduced in my company."

"I want to evaluate the actual equipment/perform a demonstration experiment"If you have any requests, please feel free to inquiry please.

Figure 3. Comparison of various monitoring devices by item

Overview of Macnica Tracks™

Here is an overview of Macnica Tracks™. (The device in the photo is the "QTS110")

An example of a dashboard: Location information is always visible. By sharing an account, both shippers and carriers can share the information in real time.

lastly

In this article, we have introduced an article about the "waiting for shipment issue", which is one of the factors of the 2024 problem of logistics, and I hope you understand that the use of technology is the key to countering that problem. In this article, we mainly introduced the functions that Macnica Tracks™ can contribute to: "delivery status visualization, advance arrival grasp by push notification, and dwell time factor analysis by open detection".

Many people may have the impression that the threshold is high when it comes to technology adoption, but Macnica Tracks™ In addition to the functions introduced in this article, has various benefits that are useful in the logistics industry. It is a system that is simple to use and easy to install just by placing a terminal. In the future, it is ideal for those who want to efficiently manage the transportation of goods and want to start managing the cold chain anew. If you are interested in the cost, please contact Macnica!

Inquiry

In this article, we introduce Macnica Tracks™For any questions, estimates, or other inquiries, please contact us using the form below.