Product Summary

This product can be used for buttons, touch displays, switches, etc. A major feature is that there is no false detection unless physical pressure is applied. The advantage of this product is that it supports a variety of input methods, environments, materials, and thicknesses. For example, it is possible to sense even when a worker is wearing gloves in a factory, or when the target object is wet or dirty with dust. It also supports a wide range of materials and thicknesses, including plastic, metal, glass, and wood. In addition, products that comply with automotive standards are also available, making it a product that can be considered for a variety of applications.

The product is available as a single sensor, a single analog front-end, or as a combination sensor and analog front-end in a single package.

Main features

- High sensitivity

- linearity

- Low power consumption

- small size

Comparison of MEMS Force Sensor and other methods

Table 1 shows a comparison with capacitive switches, infrared switches, and mechanical switches. Table 1 shows that it can be used in a variety of applications and environments. It also shows that it has advantages over other methods in terms of tuning sensitivity, RF, and EMI immunity.

| Criteria |

Qorvo Force |

Capacitive Switch |

IR |

Mechanical Switch |

| Life Cycle |

Millions |

Millions |

Millions |

100k's |

| Works When Wet |

Yes |

No |

Yes |

Yes |

| Oil、Grime、Dust Proof |

Yes |

Yes |

Yes |

No |

| Touch with Gloves |

Yes |

No |

Yes |

Yes |

| Prosthetic Finger |

Yes |

No |

Yes |

Yes |

| Any Contact Material |

Yes |

No (Plastic、Glass Only) |

No |

Yes |

| Multi Level |

Yes |

No |

No |

No |

| Intent |

Yes |

No |

Yes |

Yes |

| Tune Sensitivity |

Yes |

No |

No |

No |

| Gapless ID Integration |

Yes |

Yes |

Yes |

No |

| False positive |

No |

Yes |

No |

No |

| RF & EMI Immunity |

Yes |

No |

Yes |

Yes |

Table 1: Comparison of MEMS Force Sensor and other methods

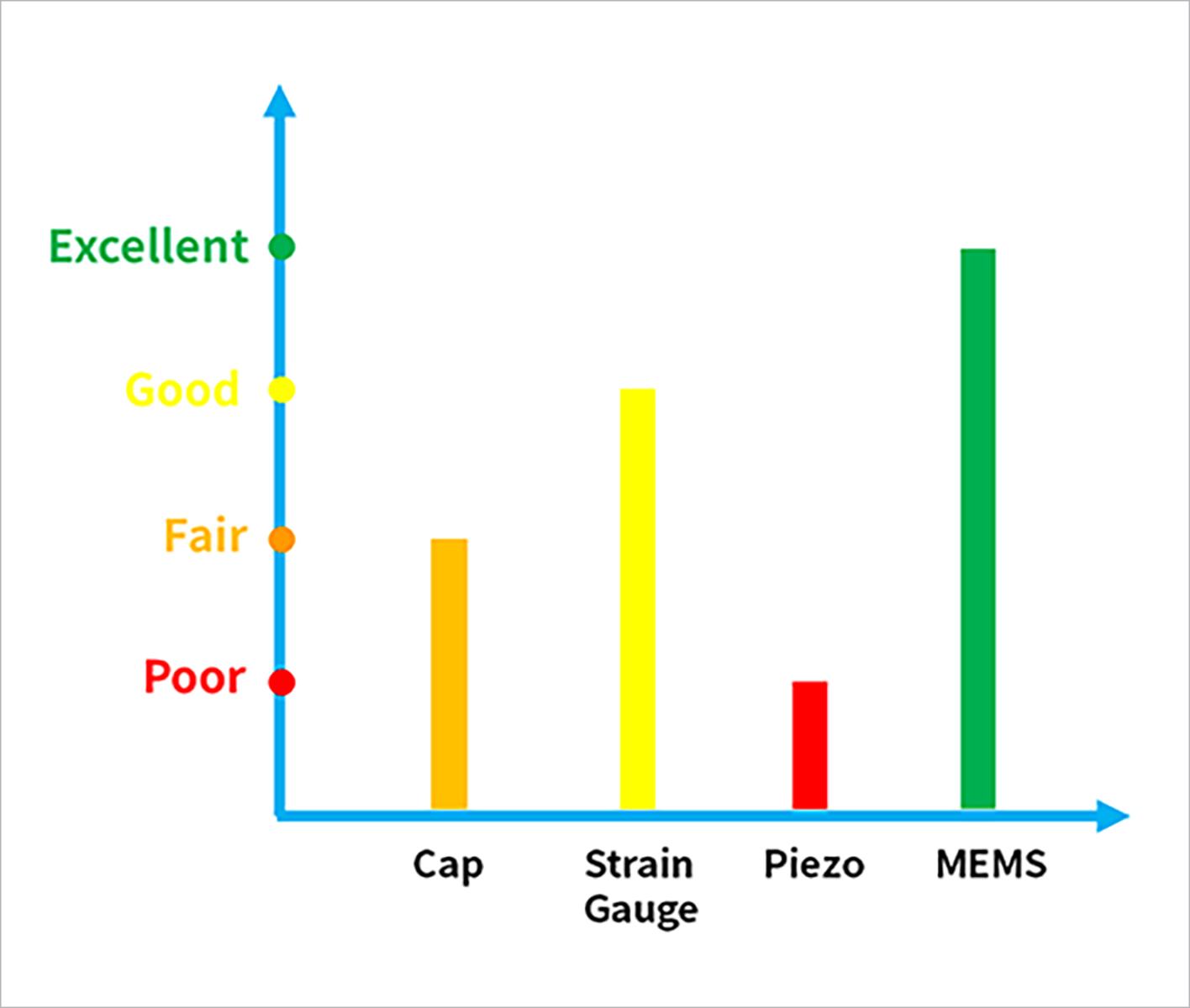

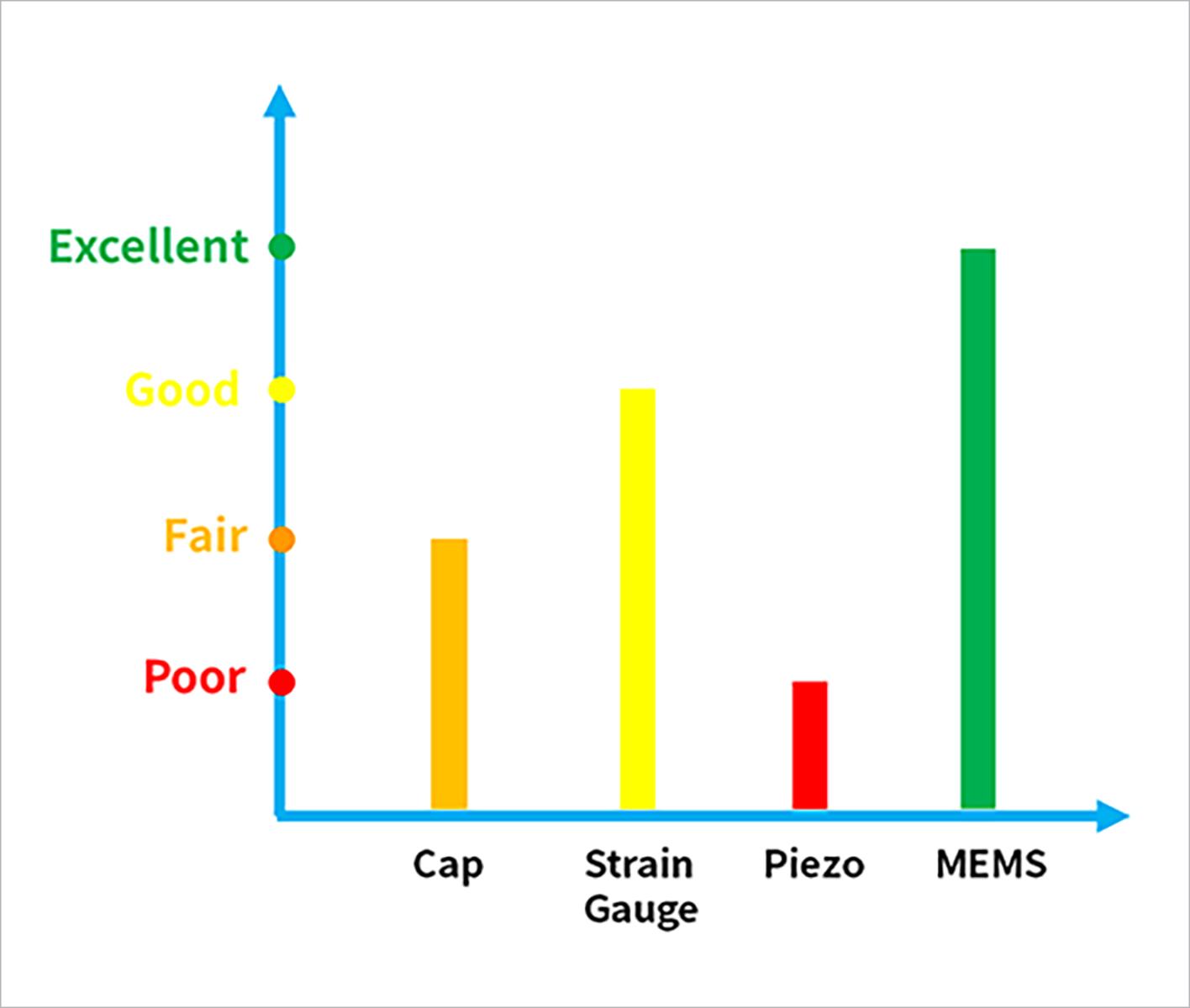

We also compared Qorvo's MEMS method with other methods in terms of accuracy (Figure 1) and uniformity (Figure 2). The comparison targets are the capacitive switch, strain gauge, and piezo method. Figures 1 and 2 show that Qorvo's MEMS method is superior.

Supports a variety of mounting methods

Qorvo's MEMS Force Sensor supports various mounting methods. The mounting methods are shown in the figure below.

Implementation method 1: Rubber, sensor, and board configuration directly below the touch surface

Mounting method 2: Rubber, board, and sensor configuration directly below the touch surface

Mounting method 3: Board and sensor configuration directly below the touch surface

Use applications

·button

・Touch display

・Switches, etc.

Evaluation Board

We have an evaluation board available to evaluate Qorvo's MEMS Force Sensor. It is possible to place the evaluation sensor board on the object you want to sense and check how it is being sensed using the dedicated software. This software allows you to adjust the sensitivity and other settings and verify it according to your actual usage.

Inquiry / Quotation

If you have any questions about this product or would like a quote, please contact us below.

Qorvo manufacturer information top page

If you want to return to Qorvo manufacturer information top page, please click below.