1. WHAT IS HYPERRAM™?

Before knowing HYPERRAM™, you need to understand HyperBus™. HyperBus™ technology was first announced in 2014 by Cypress, which said, "The HyperBus™ interface leverages the legacy capabilities of parallel and serial interface memory while increasing system performance, simplifying designs, and reducing system cost. We will realize ”, he commented. HYPERRAM™ is a new technology solution supporting the HyperBus™ interface. The first generation provided throughput of up to 333Mbytes/second, while the second generation HyperRAM™ 2.0 enabled a speedup of up to 400Mbytes/second.

2. What is the current status of HYPERRAM™ in Winbond?

Winbond Electronics has also decided to enter the market for this product in collaboration with Cypress, which first introduced HyperRAM™ in 2015. Winbond Electronics has already released HYPERRAM™ in densities of 32Mbit/64Mbit/128Mbit, with 256Mbit/512Mbit products in development. This will help Winbond Electronics further expand its product portfolio to meet diverse application needs and build a more complete ecosystem. It is currently available in 24BGA (6x8mm²) for automotive grade, 49BGA (4x4mm²) and WLCSP (Wafer Level Chip Scale Package) for consumer wearable market, and KGD (Known Good Die).

3. What is the current state of the HYPERRAM™ ecosystem?

In addition to Cypress, major MCU companies such as NXP, Renesas, ST, and TI currently offer MCUs that support the HyperBus™ interface, and their new products will continue to support this interface. . Meanwhile, the control interface development platform is also ready. Cadence, Synopsys, and Movivail have also begun offering HyperBus™ memory control IP, enabling faster design cycles for IC vendors. As a result, HYPERRAM™ has the most mature application environment compared to other Octal RAM. HYPERRAM™ also complies with JEDEC standard JESD251 Profile 2.0. Additionally, Winbond's participation in the HYPERRAM™ camp makes it the third supplier in the market after Cypress and ISSI, giving customers more choice.

4. What are the benefits of HYPERRAM™?

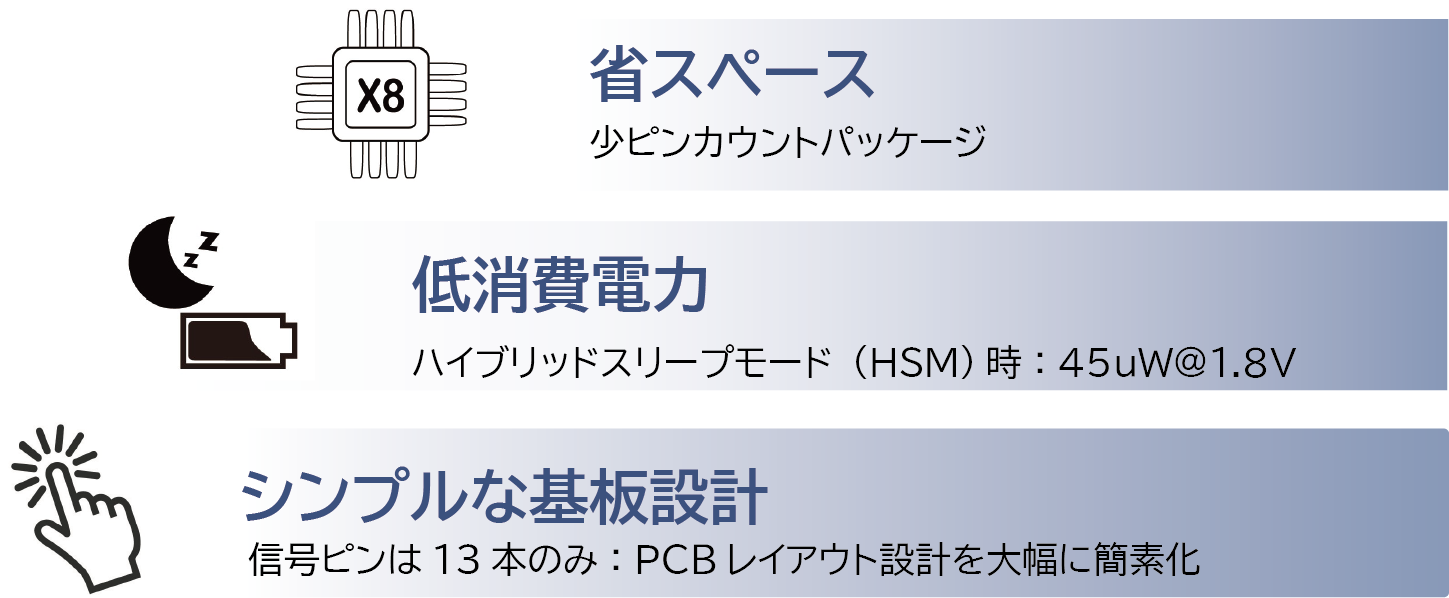

Hans Liao, DRAM Market Technology Manager, Winbond Electronics, said, "The three key features of HYPERRAM™ - low pin count, low power consumption and simple application design - will greatly improve end device performance. We are connected.”

Taking Winbond's 64Mbit HYPERRAM ™ as an example, the standby power consumption is 90uW@1.8V and 110uW@3V, while the same capacity SDRAM consumes about 2000uW@3.3V. Moreover, the power consumption of HYPERRAM ™ is only 45uW@1.8V and 55uW@3V in hybrid sleep mode(*1). This is very different from SDRAM's standby mode.

Figure 2: Power consumption comparison in standby mode and hybrid sleep mode for 64Mbit HYPERRAM™, Low Power SDRAM, pSRAM and SDRAM (Source: Winbond Electronics)

Figure 3: Power consumption comparison in operating mode for 64Mbit HYPERRAM™, Low Power SDRAM, pSRAM and SDRAM

(Source: Winbond Electronics)

Even with Low power SDRAM, the form factor is larger than HYPERRAM ™ and requires more PCB area, so this is not an ideal solution.

Additionally, the HYPERRAM ™ has only 13 signal pins, which greatly simplifies PCB layout design. Also, when designing the end product, it is possible to realize other functions with more pins of the MCU, or to use the MCU with fewer pins to improve cost efficiency.

Simplified control interface is another feature of HYPERRAM ™. Based on the pSRAM architecture, HYPERRAM ™ has a self-refresh function (*2) and can automatically return to standby mode. This simplifies system-side memory specifications and simplifies firmware and driver development.

5. How is HYPERRAM™ positioned compared to other DRAM products?

Compared to other DRAM products, HYPERRAM™ has lower pin count and lower power consumption while operating at the same bandwidth. In addition, it offers customers the choice of a new interface HyperBus™.

Figure 4: Comparison of pin count and power consumption between HYPERRAM™ and other DRAM products

(Source: Winbond Electronics)

6. What applications and industries is HYPERRAM™ suitable for?

HYPERRAM™ is ideal for applications requiring low power consumption and high MCU computing power in the automotive, Industrial 4.0, smart home and wearable markets. Examples include instrument clusters, HMI industrial control panels, smart home devices, voice control devices, in-vehicle computers and smart bands. In addition, characteristics such as low cost, low power consumption, and computational efficiency are also suitable for IoT edge device applications.

Figure 5. HYPERRAM™ HMI usage example (Source: Winbond Electronics)

And for battery-powered devices such as smart speakers and smart meters, low power consumption becomes increasingly important as battery life is key to product success, along with rich IoT capabilities and easy-to-use human interfaces. In addition to using a low-power MCU, other low-power peripheral components should also be considered to achieve long battery life, and HYPERRAM ™ is designed for this.

(*1) Hybrid Sleep Mode (HSM):

Hybrid sleep mode is one of the power saving modes that allows memory data retention while most of the internal circuitry is disconnected. It was designed for battery-powered products and products with long standby times.

(*2) Self refresh:

In DRAM, each bit of memory data is stored as the presence or absence of charge on a small capacitor on the chip. Over time, the charge in memory cells leaks. Therefore, without a refresh, the stored data will eventually be lost. To prevent this, an external circuit periodically reads and rewrites each cell, restoring the charge on the capacitor to its original level.

Also, Winbond's datasheet states that "The self-refresh command allows the DRAM to retain data even when the rest of the system is powered off. The DRAM in self-refresh mode can read data without an external clock. holds.”

Product introduction page

・ Click here for the product introduction page.

Inquiry

If you have any questions regarding this article, please contact us below.

Back to Winbond Manufacturer Information Top

If you want to return to Winbond manufacturer information top page, please click below.